A handheld self-adaptive laser cleaning device with folded optical path

A laser cleaning and hand-held technology, applied in the field of laser cleaning, can solve the problems of the normal service life of the equipment, low cleaning efficiency, weak fiber coupling interface with maximum transmission length and minimum bending radius, and improve the quality and efficiency of cleaning and processing. , The overall size is compact and compact, and the effect of improving the normal service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

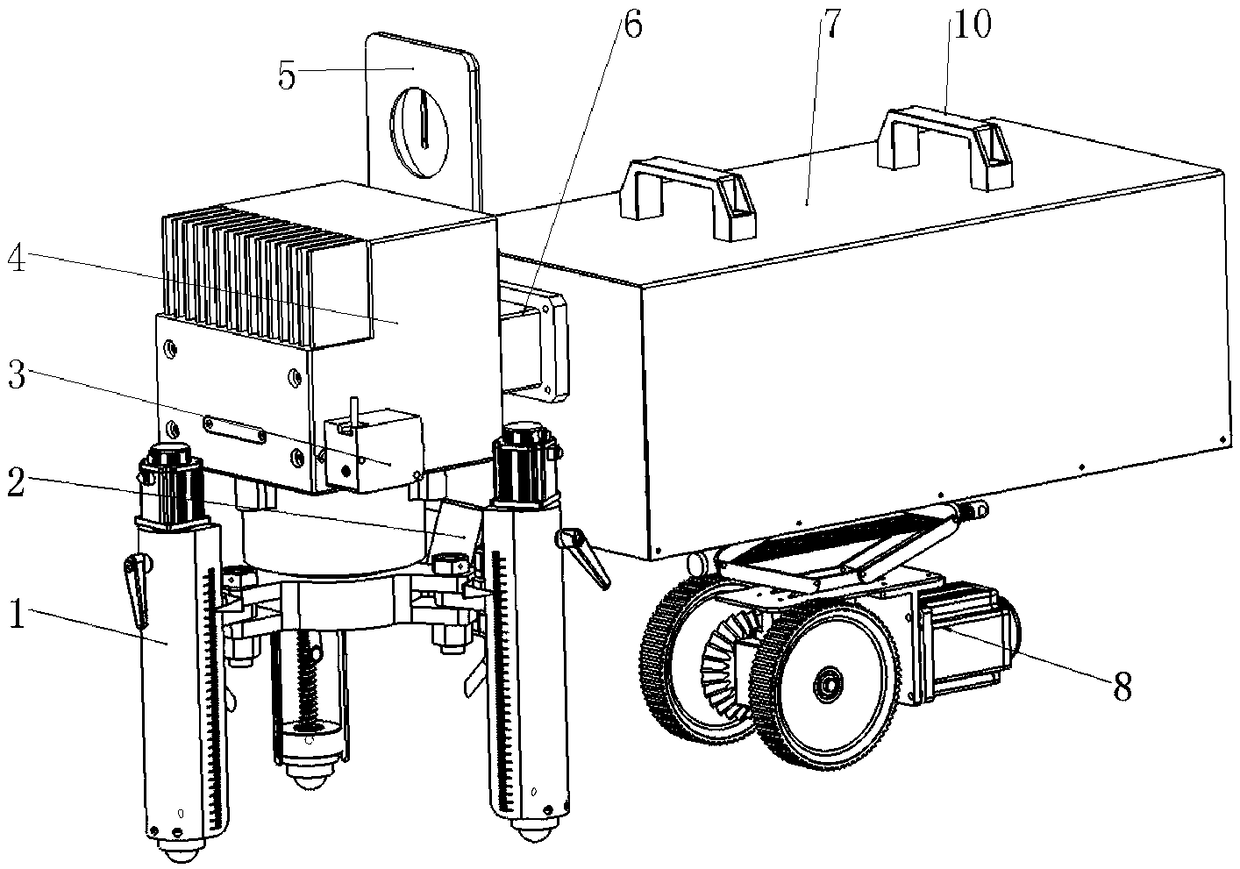

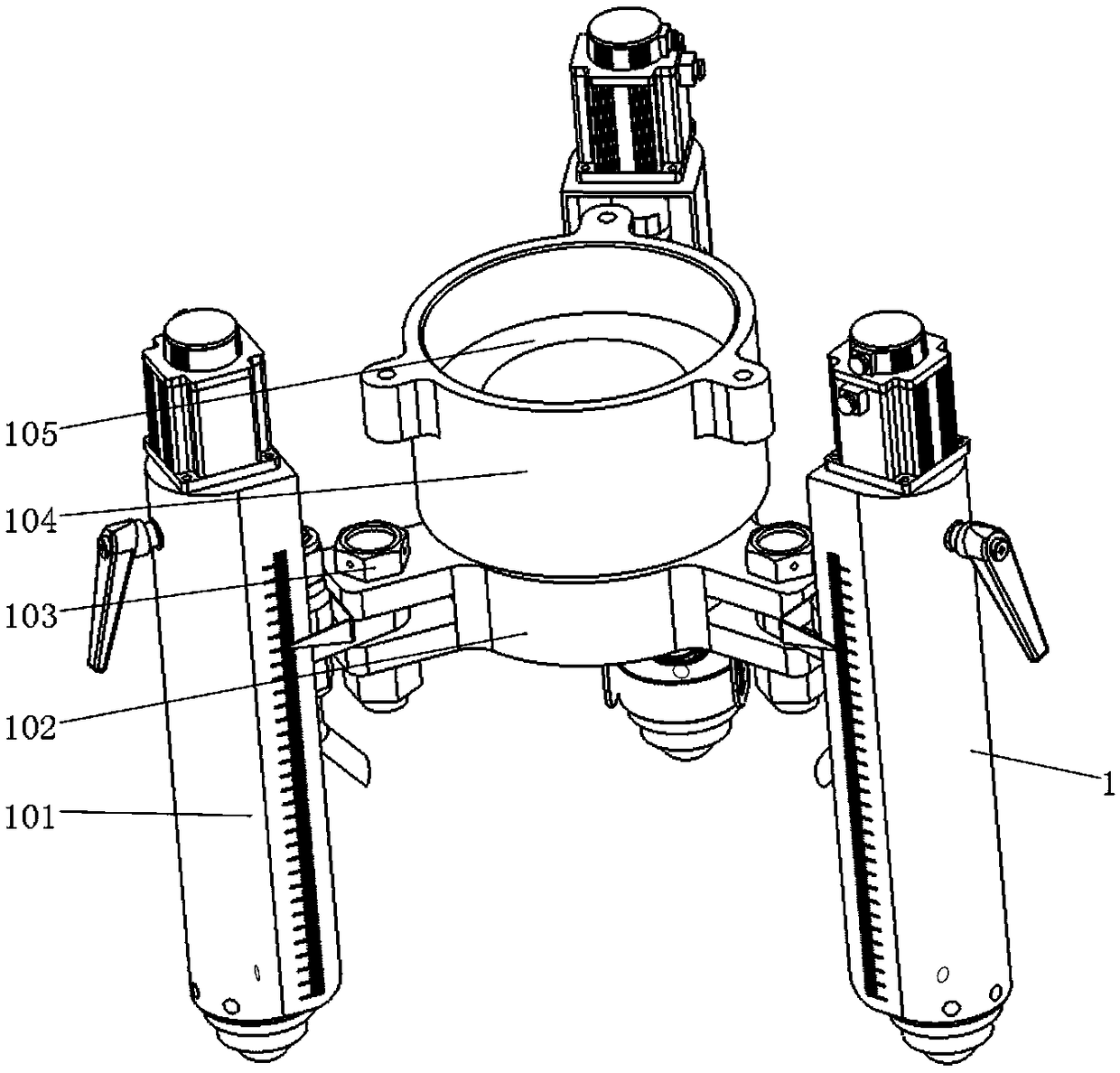

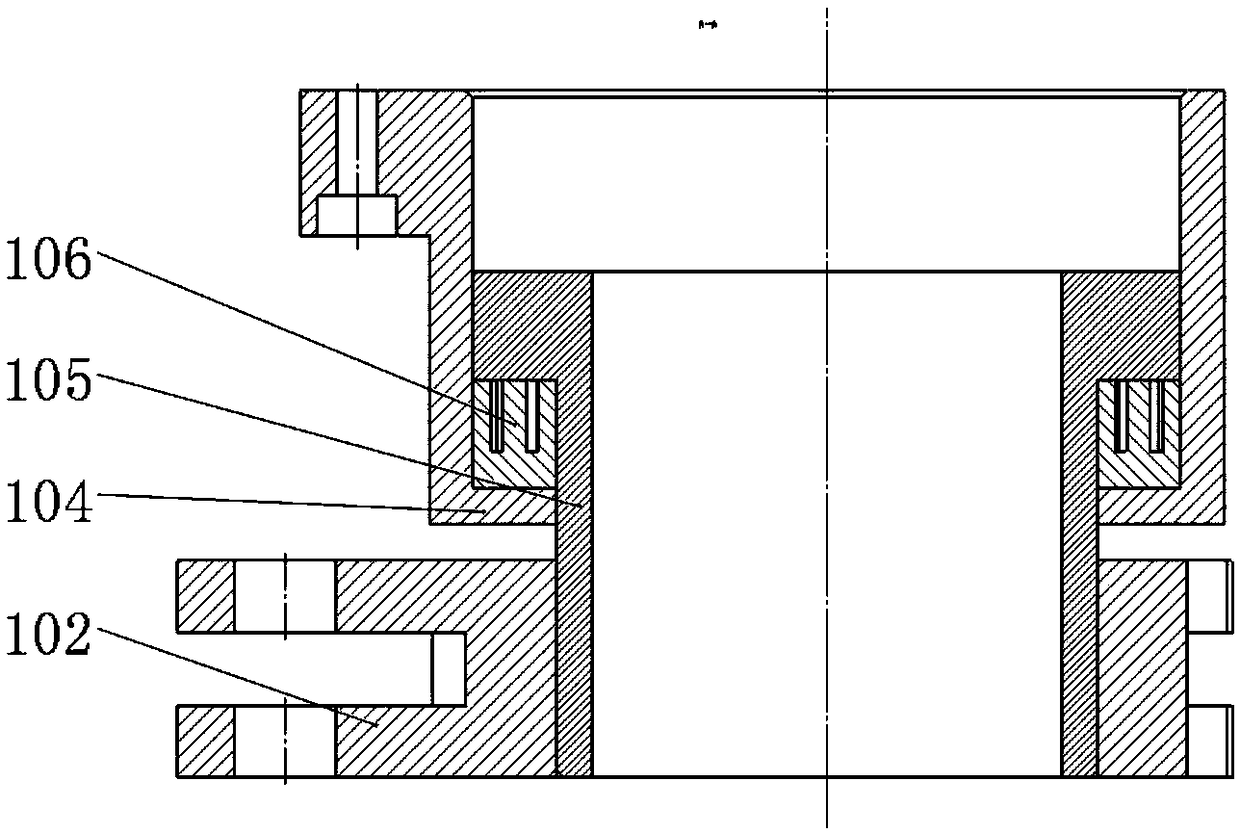

[0045] Such as Figure 1-9 As shown, the present invention provides a hand-held self-adaptive laser cleaning device with folded optical path, which includes a lifting focusing assembly 1, a laser distance measuring sensor 3, a galvanometer scanning system 4, a lifting guide electric drive assembly 8 and a laser-folding optical path system.

[0046] The galvanometer scanning system 4 is used to realize that the incident laser beam is reflected by the deflection scanning lens driven by the motor and transmitted through the fixed focal length objective lens, and then emitted, focused on the surface of the workpiece, and the laser beam is scanned on the surface of the workpiece according to the set trajectory Movement: a lifting focus assembly 1 is arranged below the laser beam exit end of the galvanometer scanning system 4, and a laser d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com