Pellet chain grate bulk material comprehensive treatment method and system

A comprehensive processing and chain grate technology, which is applied in data processing applications, furnaces, instruments, etc., can solve the problem that the internal recycling of materials in the pelletizing plant cannot be realized, the service life of the conveyor belt of the belt conveyor can be reduced, and the material occupied by bulk material transportation can be solved. yard and other problems, so as to improve the operation efficiency of the stockyard, reduce the storage cost, and reduce the input cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

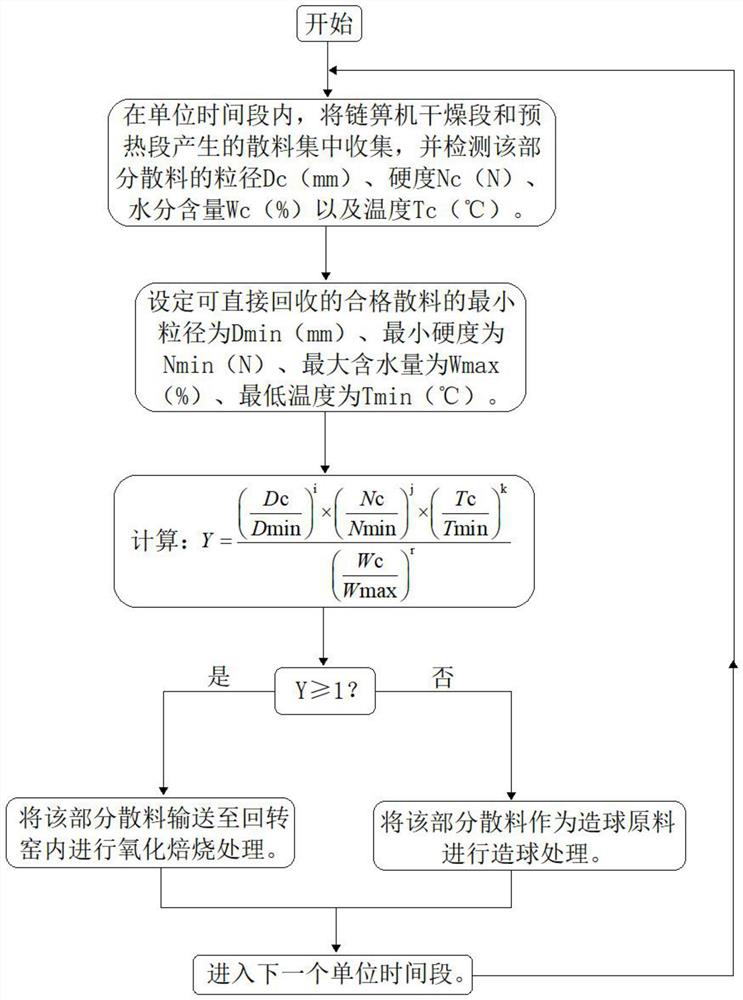

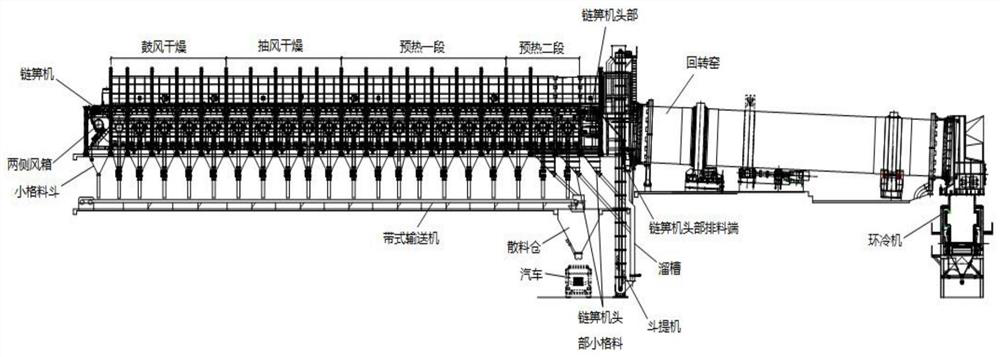

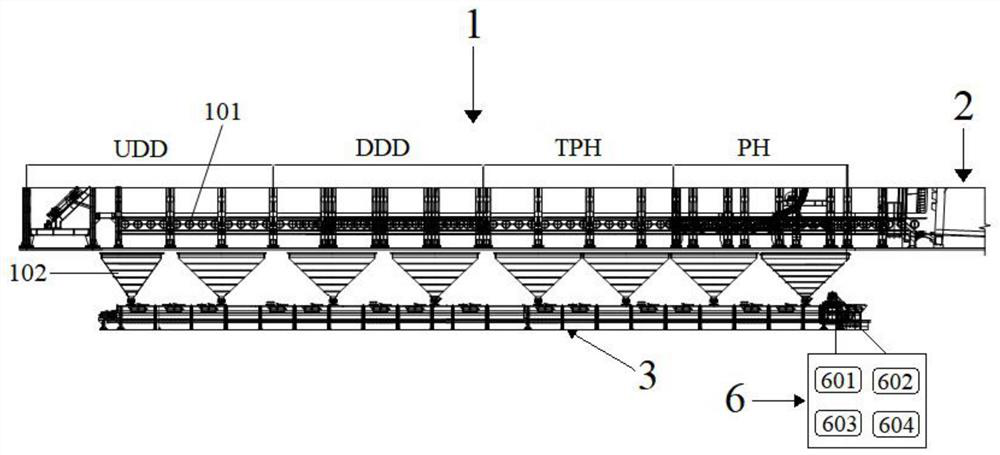

[0110] Such as image 3 and 4 As shown, a system for the comprehensive processing of pellet chain grate machine bulk materials or a system for the method for comprehensive processing of pellet chain grate machine bulk materials described in the first embodiment: the system includes chain grate machine 1, rotary Kiln 2, bulk material centralized collection and treatment device 3. The discharge port of the chain grate machine 1 communicates with the feed port of the rotary kiln 2 . The chain grate machine 1 includes a drying section and a preheating section. The bulk material centralized collection and processing device 3 is arranged below the drying section and the preheating section of the chain grate machine 1 . The discharge end of the bulk material centralized collection and processing device 3 is connected to a transition bin 6 for materials to be inspected. The material transition bin 6 is provided with a material particle size detection unit 601 , a material hardness...

Embodiment 2

[0112] Repeat Example 1, except that the drying section of the chain grate machine 1 includes a blast drying section UDD and a draft drying section DDD. The preheating section of the chain grate machine 1 includes a section of preheating TPH and a section of preheating PH. The blast drying section UDD, the draft drying section DDD, the first stage of preheating TPH and the second stage of preheating PH are sequentially arranged in series. Hot air boxes 101 are arranged on both sides of each of the blast drying section UDD, the draft drying section DDD, the preheating stage TPH and the preheating second stage PH. A small compartment hopper 102 is provided below each of the blast drying section UDD, the draft drying section DDD, the preheating section TPH and the preheating section 2 PH. The bulk material centralized collection and processing device 3 is located below the small cell hopper 102 of the blast drying section UDD, the draft drying section DDD, the preheating section...

Embodiment 3

[0114] Repeat Example 2, such as Figure 5 As shown, only the bulk material centralized collection and processing device 3 includes a first conveyor 301 , a screening machine 302 , a second conveyor 303 and a third conveyor 304 . The first conveyor 301 is arranged below the small cell hopper 102 of the blast drying section UDD, the draft drying section DDD, the preheating section TPH and the preheating section PH. The screening machine 302 is arranged at the discharge end of the first conveyor 301 . The outlet of the screened material of the screening machine 302 is connected with the inlet of the transition bin 6 for the material to be inspected through the second conveyor 303 . The discharge port of the underscreen material of the screening machine 302 is connected with the feed port of the crusher 7 through the third conveyor 304 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com