Process for preparing foam composite material of magnesium alloy-pearlite

A composite material and magnesium alloy technology, applied in the field of magnesium alloy-perlite foam composite material and its preparation, can solve the problems of corrosion protection of environmentally friendly foam magnesium products, reasonable design, lack of property protection, and increase of composite materials, etc. Achieve the effects of easy industrial mass production, low equipment depreciation cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

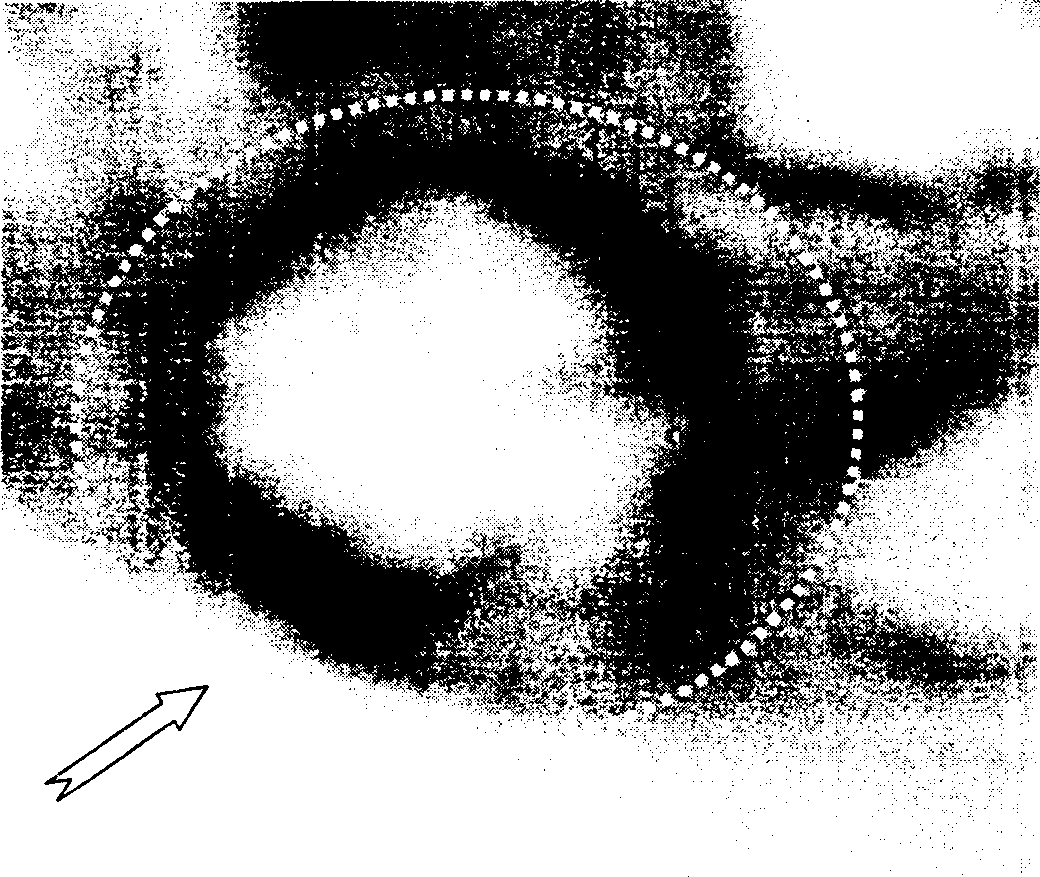

[0011] Use 200-mesh aluminum powder and polyvinyl alcohol dilute solution to prepare aluminum powder slurry, and spray the aluminum powder slurry to the particle size interval V p On the surface of expanded perlite particles with openings of 14 mesh to 40 meshes, hot air drying, the weight of aluminum powder sprayed on the surface of expanded perlite with openings is 1.5% of the weight of expanded perlite, and then the expanded perlite containing aluminum powder on the surface The pearl particles are put into the vacuum suction casting mold, the gap between the particles is adjusted by the vibration method to adjust the air permeability, and the vacuum pump is started to make the vacuum degree of the vacuum tank reach 0.06Pa. The AZ91 magnesium alloy is heated and melted at a temperature T c Controlled at 670°C±5°C, the alloy liquid is connected to the suction casting port, the vacuum hand valve is opened to start suction casting, the speed of suction casting is controlled by ...

Embodiment 2

[0013] V p =14 mesh~24 mesh; The weight of the aluminum powder that is sprayed on the expanded perlite surface of opening is 4% of the weight of expanded perlite; T c =750°C±5°C; V c =0.5m / s, the magnesium alloy-perlite foam composite material of the present invention is obtained. Among them, ρ=1.18g / cm 3 ; σ max =221MPa; σ y =78MPa. All the other are with embodiment 1.

Embodiment 3

[0015] Mix calcium carbonate powder of equal weight in the aluminum powder; V p =8 mesh~18 mesh; The weight of the mixed powder of aluminum powder and calcium carbonate powder sprayed on the surface of open-cell expanded perlite is 2% of the weight of open-cell expanded perlite; T c =700°C±5°C; V c =0.1m / s, the magnesium alloy-perlite foam composite material of the present invention is obtained. Among them, ρ=1.24g / cm 3 ; σ max =179MPa; σ y =82MPa. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com