A system and method for pyrolysis conversion and utilization of self-adhesive waste

A waste and pyrolysis technology, which is applied in special forms of dry distillation, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as waste of valuable resources, restrictions on self-adhesive adhesives, and increased environmental burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

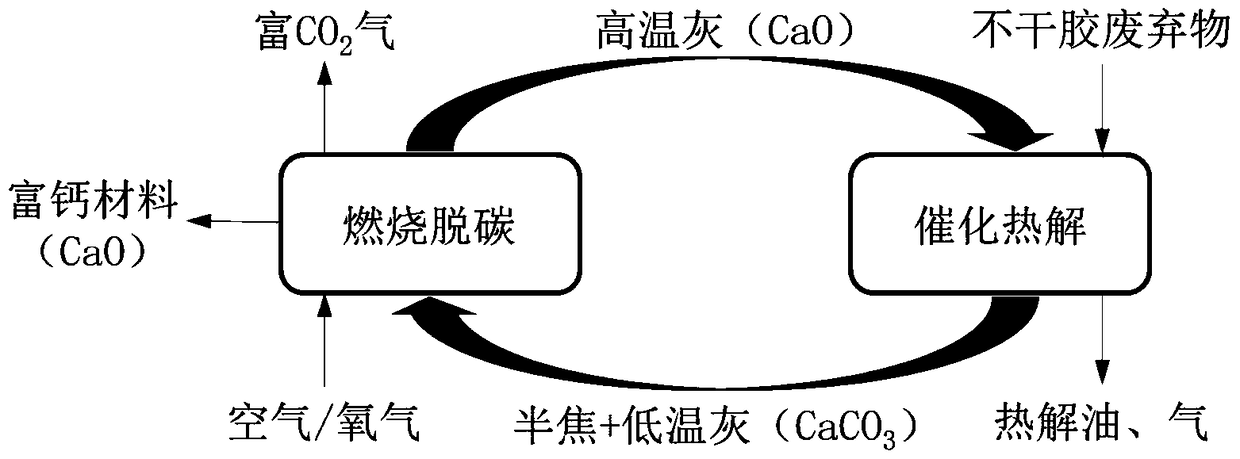

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

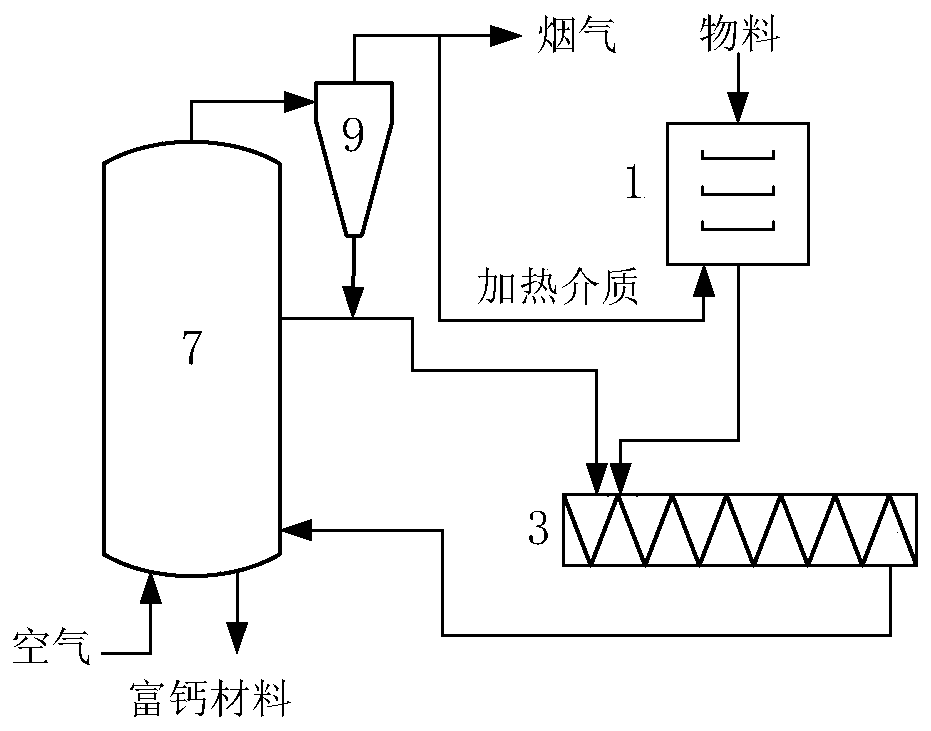

Embodiment 1

[0070] Send the raw material of adhesive waste crushed to 1-5cm into the rotary kiln preprocessor, and then fully heated after countercurrent contact with the hot flue gas heating medium fed from the bottom of the rotary kiln preprocessor, the temperature of the rotary kiln preprocessor is controlled at 240°C. The chlorine-containing substances in the self-adhesive waste decompose to produce hydrogen chloride, which enters the lime milk absorption pool under the entrainment of the heating medium flow; the pretreated material enters the paddle type pyrolysis reactor, and is sent by the heat carrier conveying device. The high-temperature fuel ash is fully mixed, and rapid catalytic pyrolysis is carried out under the action of calcium oxide in the fuel ash. The temperature of the paddle-type pyrolysis reactor is controlled at 500°C to produce a mixture of pyrolysis semi-coke and pyrolysis oil gas; pyrolysis oil gas The mixed product is separated by the first gas-solid separation ...

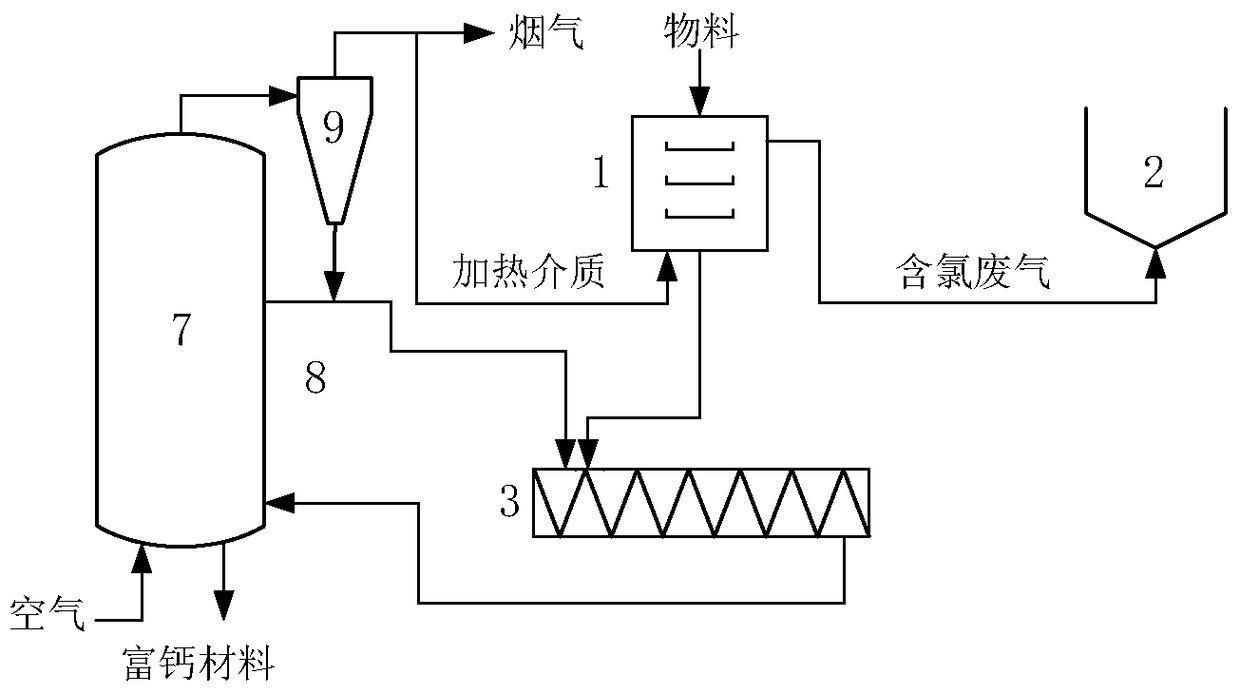

Embodiment 2

[0072] In this example, the same experimental method and steps as in Example 1 are adopted, the difference is that the particle size of the self-adhesive waste raw material is controlled at 0.1-1 cm; The temperature of the preprocessor is controlled at 350°C; the heating medium is steam generated by heat exchange of hot flue gas; The reactor adopts a riser-type combustion reactor, and the temperature of the combustion reactor is controlled at 700°C.

Embodiment 3

[0074] In this embodiment, the same experimental method and steps as in Example 1 are adopted, the difference is that the particle size of the self-adhesive waste raw material is controlled at 5-10 cm; the preprocessor adopts a spiral downflow preprocessor, and the preprocessor temperature At 150°C; the heating medium is steam generated by heat exchange during the condensation process of pyrolysis gas phase products; the auxiliary gas is oxygen; the pyrolysis reactor adopts a spiral pyrolysis reactor, and the temperature of the pyrolysis reactor is controlled at 300°C; the combustion reactor adopts a boiling furnace Combustion reactor, the temperature of the combustion reactor is controlled at 850°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com