Synthetic method of polyaniline

A synthesis method and polyaniline technology are applied in the field of inexpensive and environmentally friendly synthesis of polyaniline, can solve the problem of high synthesis cost, and achieve the effects of satisfying industrial production, shortening the initiation latency period, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix hydrochloric acid, aniline and water, and prepare 1.0 L of a mixed aqueous solution of aniline and hydrochloric acid with a hydrochloric acid concentration of 1.5 mol / L and aniline concentration of 0.2 mol / L in a reactor.

[0021] Then add ferrous chloride aqueous solution to the reactor under stirring, then slowly add hydrogen peroxide to the reactor under stirring until the concentration of ferrous chloride in the mixed system reaches 10 -5 mol / L, the concentration of hydrogen peroxide reaches 3×10 -2 mol / L. Then, 1.0 L / min air was bubbled into the mixed aqueous solution of aniline and hydrochloric acid to carry out the polymerization reaction of aniline. Air was introduced to react for about 6 hours, and then the reaction solution was dried with a dryer to obtain the solid phase after the reaction, washed with a small amount of water, then dried, and dried at 80°C for 48 hours to obtain the polyaniline product.

Embodiment 2

[0023] Mix hydrochloric acid, aniline and water, and prepare 1.0L of a mixed aqueous solution of aniline and hydrochloric acid in a reactor with a hydrochloric acid concentration of 1.0 mol / L and an aniline concentration of 0.5 mol / L.

[0024] Then add ferrous sulfate aqueous solution to the reactor under stirring, then slowly add hydrogen peroxide to the reactor under stirring until the concentration of ferrous sulfate in the mixed system reaches 10 -5 mol / L, the concentration of hydrogen peroxide reaches 3×10 -2 mol / L. Then, 2.0 L / min air was bubbled into the mixed aqueous solution of aniline and hydrochloric acid to carry out the polymerization reaction of aniline. Air was introduced to react for about 8 hours, and then the reaction solution was dried with a dryer to obtain a solid phase after reaction, which was washed with a small amount of water, then dried, and dried at 80°C for 48 hours to obtain polyaniline products.

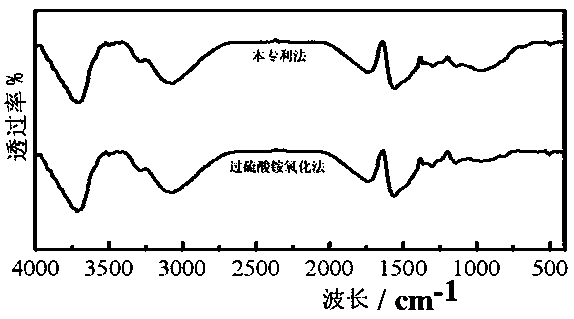

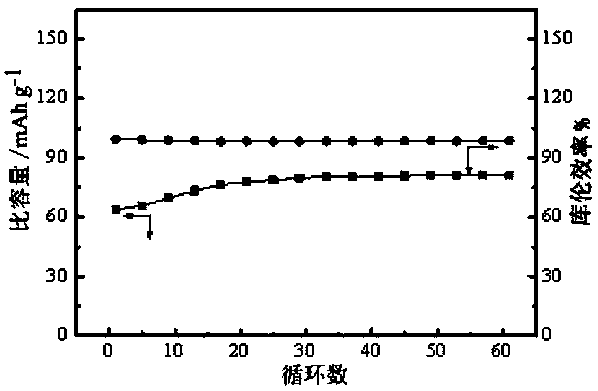

[0025] two, figure 1 For adopting the polyan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com