Method for embedding thin plate metallographic sample

A metallographic sample and thin plate technology, which is applied in the field of inlaid thin plate metallographic samples, achieves the effects of reducing consumables, shortening sample preparation and image acquisition time, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

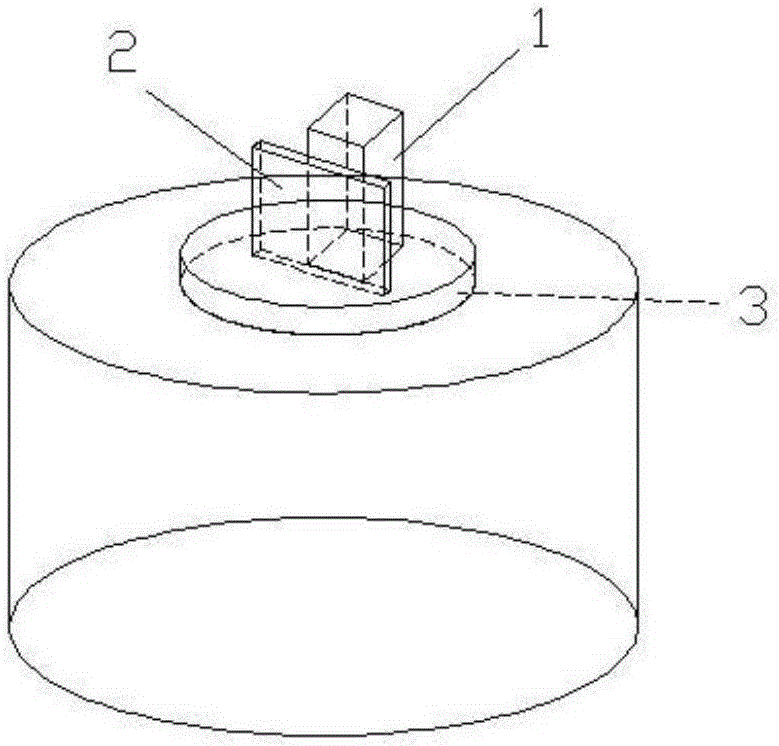

[0027] Ten thin plate specimens 2 (0.5 mm) were mounted using this method. Bind the thin plate sample 2 on the waste sample with glue, put the whole sample into the mosaic machine, set the mosaic parameters, the mosaic result is: the surface of the thin plate sample is smooth, the purpose of edge protection is achieved, and it is easy to collect metallographic photos and data analyze.

Embodiment 2

[0029] After using this method, the three failed thin plate samples 2 were inlaid. Sheet sample 2 is a cold-rolled sheet product (thickness 0.8mm) of DC04 produced by a steel factory. Cracks occurred during stamping deformation. Due to stamping deformation, the thickness of the failure part is very thin. The sheet sample 2 was bound with adhesive tape On a waste sample 1, put it into the mosaic machine as a whole, set the mosaic parameters, the mosaic result is: the defect surface of the thin plate sample 2 is flat, retaining the original state of the sample, providing a real and powerful original for failure analysis data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com