Construction method of a rainproof and seepage-proof indoor solid waste landfill

A construction method and landfill technology, applied in construction, industrial construction, soil protection and other directions, can solve the problem of site selection, construction difficulty, can not meet the requirements of solid waste (hazardous waste) pollution prevention and control, leachate two secondary pollution and other problems, to achieve the effect of reducing site selection limitations, increasing landfill capacity, and reducing capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The landfill built in the embodiment of the present invention is built in the environmental protection industry base.

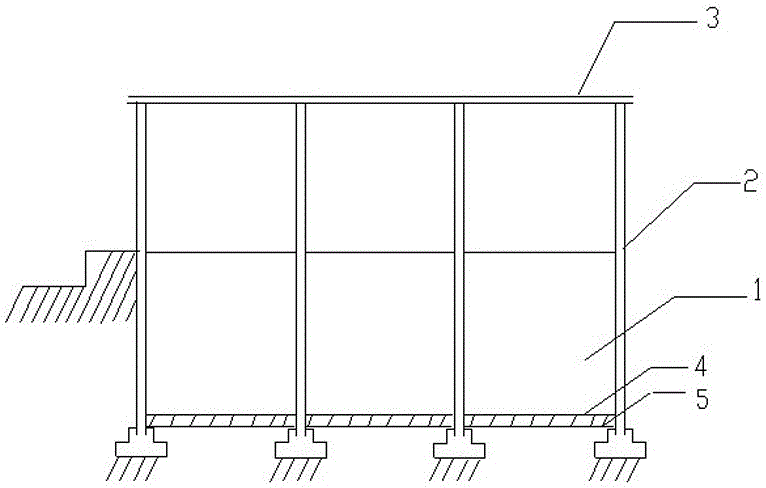

[0022] Such as figure 1 As shown, the landfill built by the present invention mainly includes a landfill 1, a column 2, a roof 3, a base soil anti-seepage layer 4 and an engineering membrane anti-seepage layer 5.

[0023] When excavating, the excavated earth shall be piled up around to reduce earth transportation and increase the volume of landfill 1. The depth of landfill 1 shall be controlled at 5-6 meters below the ground and 1-2 meters above the ground.

[0024] After the landfill 1 is dug, the building foundation construction is carried out. The structure adopts reinforced concrete, and then the column 2 and the roof 3 of the building are built. The span of the column 2 is designed according to the economic span, and the roof 3 adopts organized drainage.

[0025] After the above work is completed, the anti-seepage treatment of the base soil of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com