Steel pipe bending machine and forming process thereof

A technology for bending machines and steel pipes, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of lower production efficiency, large deformation of steel pipes, and unclear, etc., and achieve reasonable structural design, small deformation of steel pipes, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

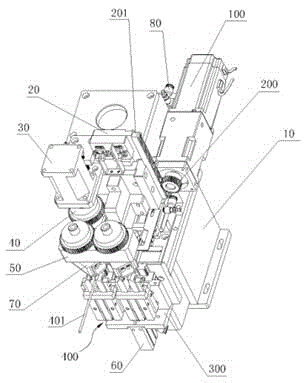

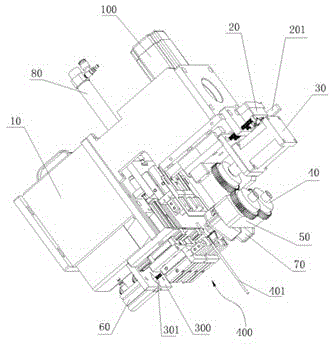

[0018] refer to Figure 1~3 , a steel pipe bending machine, including a base 10, the base 10 is provided with a cylinder 100, the end of the cylinder 100 is provided with a gear 200, the gear 200 meshes with the rack 201, and the gear 200 is on the rack 201 can lift and slide, the rack 201 is fixed on the baffle plate 20 on the base 10, the base 10 is also provided with a motor 30, the lower end of the motor 30 is provided with a transmission gear set 40, and the transmission gear Group 40 drives the steel pipe to move to ensure the process feed of the steel pipe bending machine.

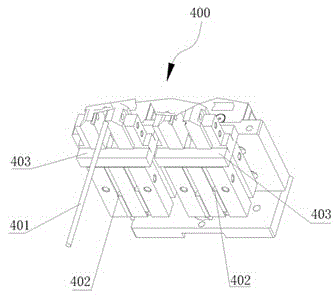

[0019] The lower end of the transmission gear set 40 is provided with a spacer 50, and the lower part of the spacer 50 is provided with a pneumatic control switch 70, which is used to control the opening and closing of the steel pipe bending machine. The front end of the base 10 is provided with a There is a workbench 300, the lower end of the workbench 300 is provided with a lifting cylinder 60, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com