Circular cutter

A cutter and circular technology, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of not easy to cut a circle, judgment errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

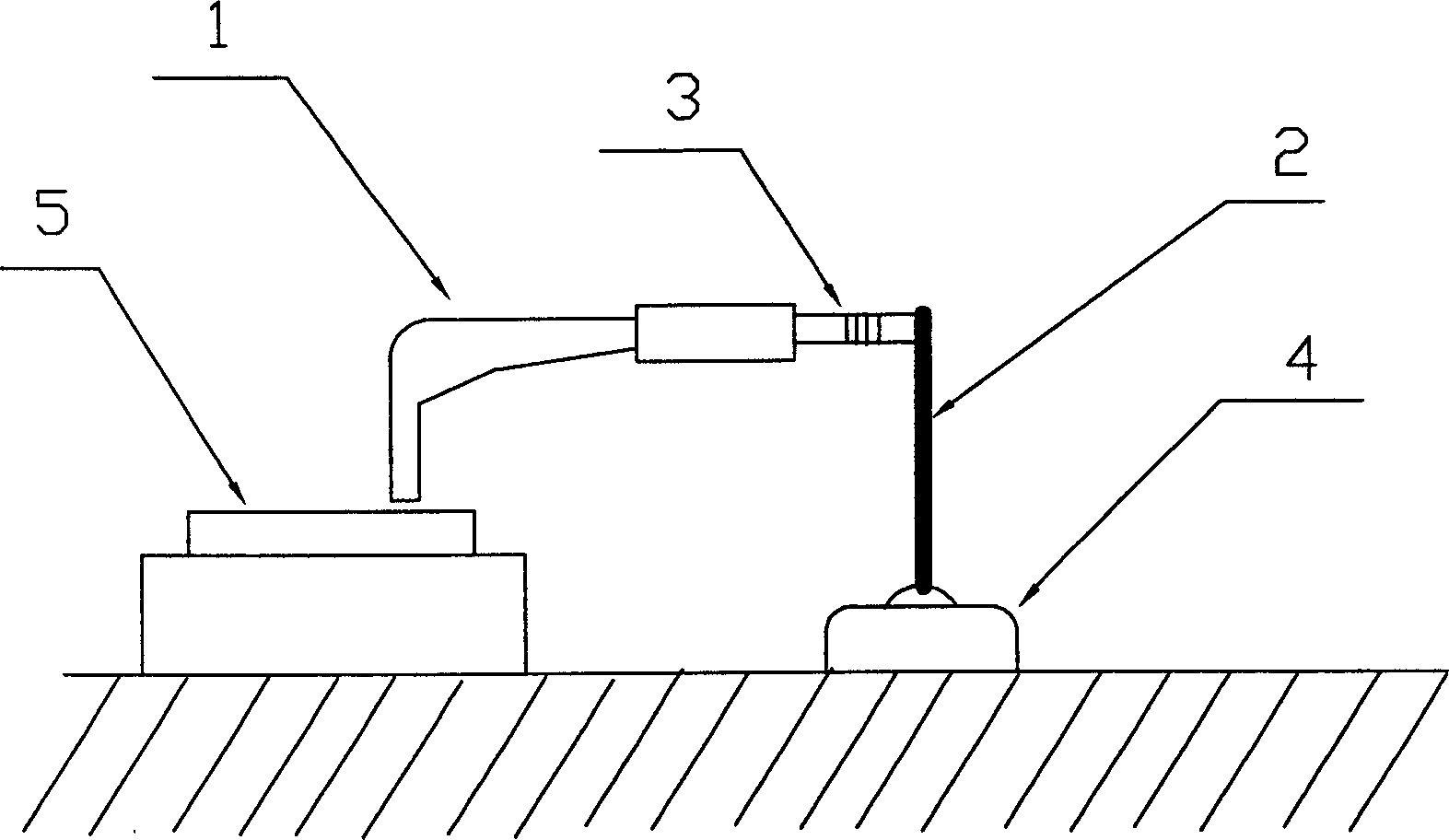

[0005] As shown in the figure, a cutting torch 1, a shaft handle 2, a cutting torch handle 3, a base 4 and a steel plate 5. Both the torch handle 3 and the shaft handle 2 adopt a retractable structure. The torch handle 3 forms an angle of 90° with the axel 2. Shaft 2 is connected with base 4 and can rotate on the base. Base 4 keeps cutting torch 1 stable by its own weight. Before cutting the steel plate 5, adjust the length of the torch handle 3 and the height of the shaft handle 2, then ignite and cut the steel plate 5, and push the torch handle 3 to rotate around the shaft handle 2 to cut out the required arc-shaped steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com