Arc-shaped rounding mechanism for rounding ridge part of book block

A curved and book block technology, applied in book binding, book binding flattening machine, printing, etc., can solve the problems of general round efficiency and small contact area, and achieve good quality, uniform arc surface and smooth arc Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings.

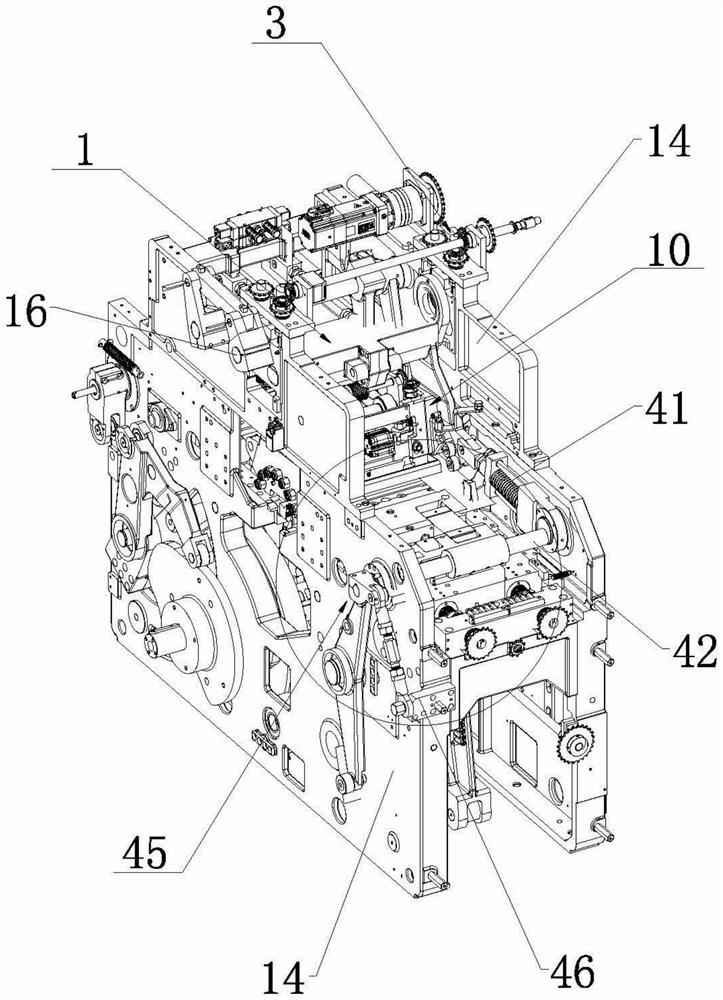

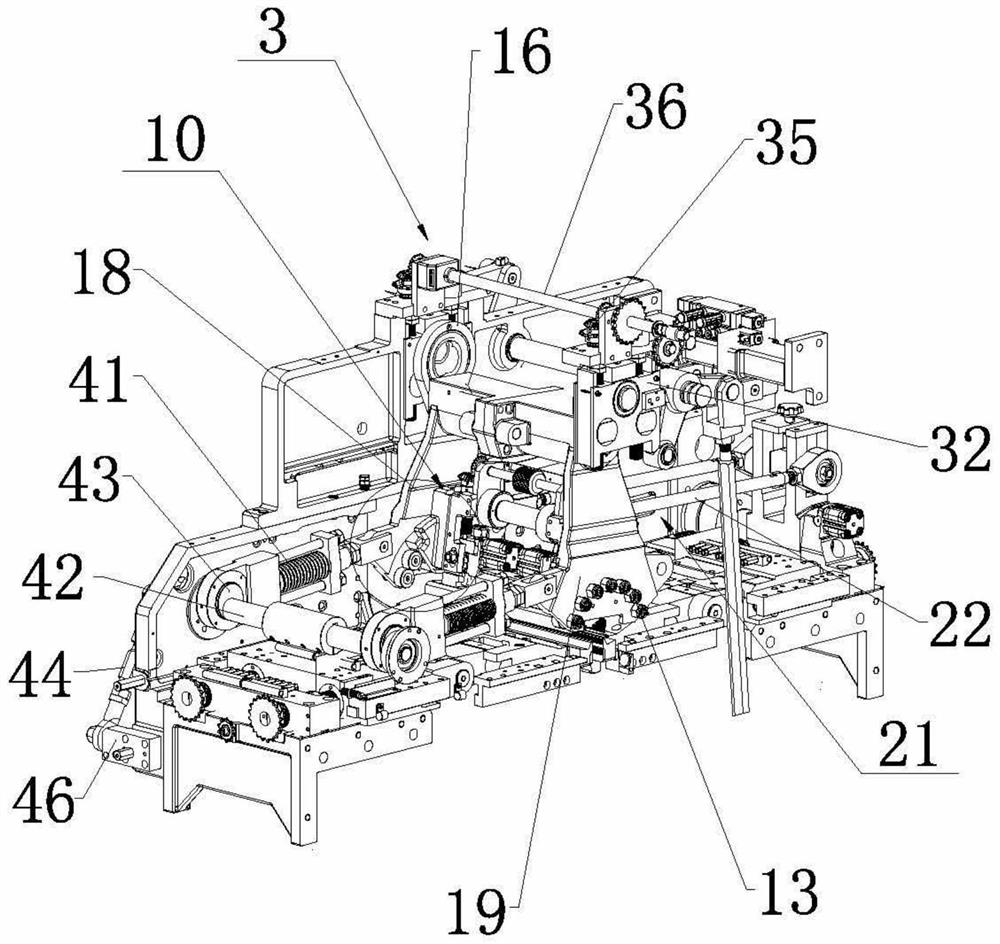

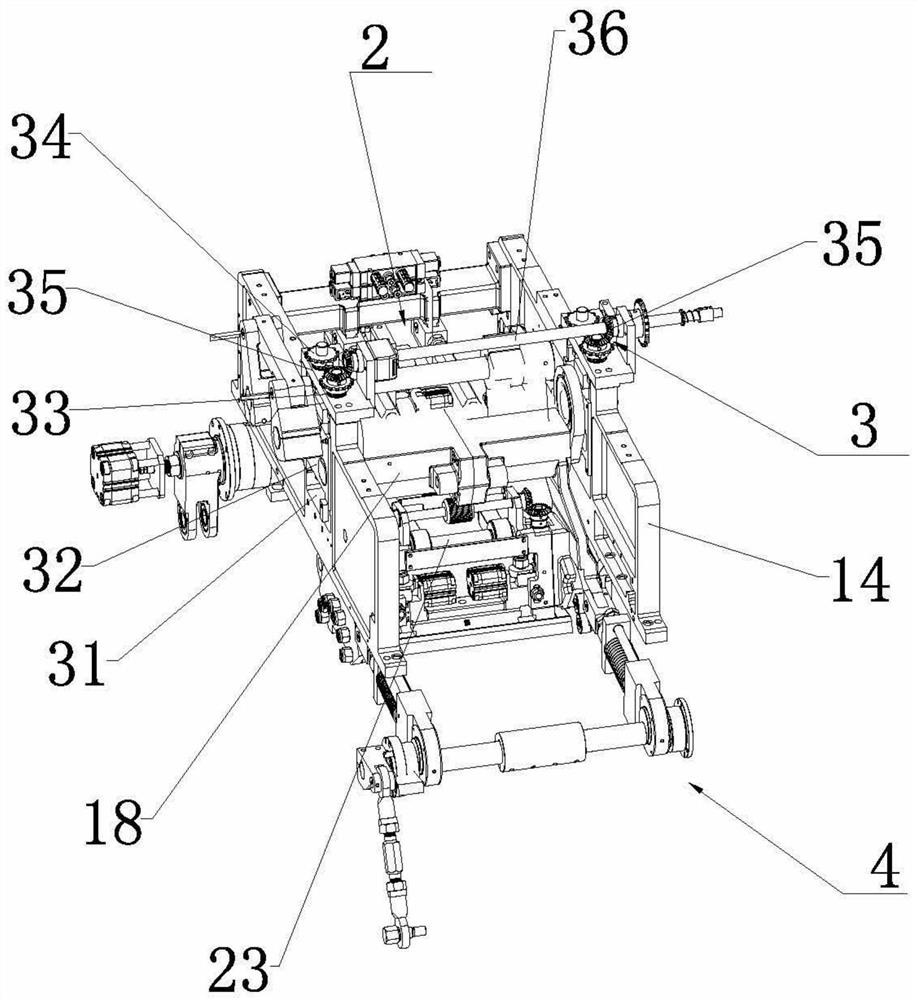

[0035] like Figure 1-6 As shown, an arc-shaped rounding mechanism for rounding the spine of the book block includes a full-round mold 1 for fitting the spine of the book block, and the full-round mechanism also includes a full-round mold 1 for driving the round mold 1 The arc-shaped swinging arc drive mechanism 2 and the longitudinal drive mechanism 4 for longitudinal movement; the full-circle mold 1 includes a mold assembly 10 and a guide mounting seat 18 for installing the mold assembly 10. The mold assembly 10 includes an arc-shaped track 12 and a The arc-shaped friction surface 11 which is in frictional contact with the spine of the book block in an arc-shaped motion, and the guide mounting seat 18 is provided with a guide moving piece that moves on the arc-shaped track 12 .

[0036] After the book block is clamped and positioned on both sides by the clamping mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com