Method for constructing special-shaped solid concrete structure through wet sprayed concrete technique

A technology of concrete structure and shotcrete, which is applied in the field of shotcrete, and can solve the problems of low production efficiency, pulse phenomenon of spraying material, and affecting the quality of shotcrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention is exemplified below by describing the construction process of a water slide with a special-shaped trough section using the method provided by the present invention.

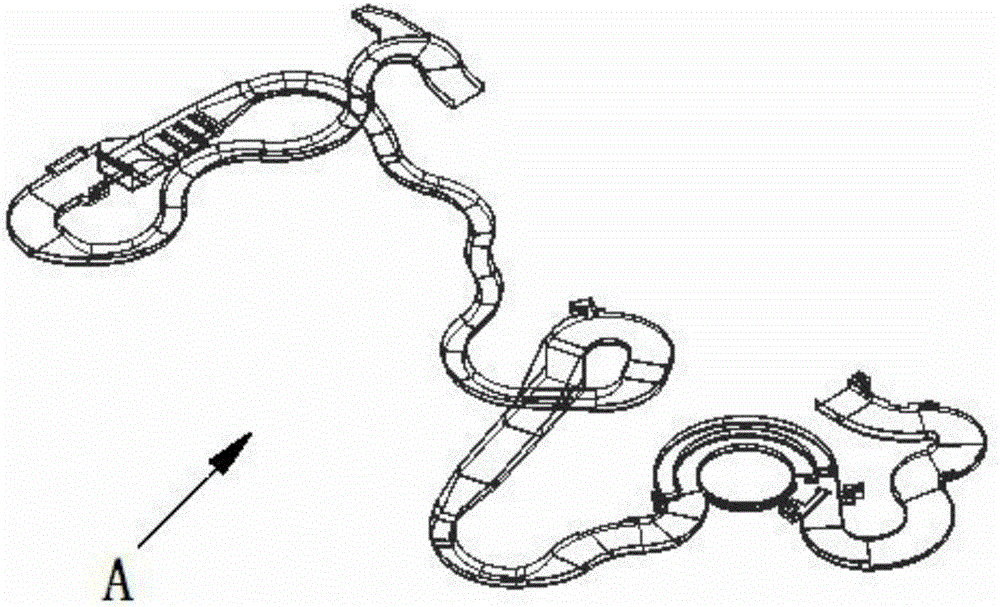

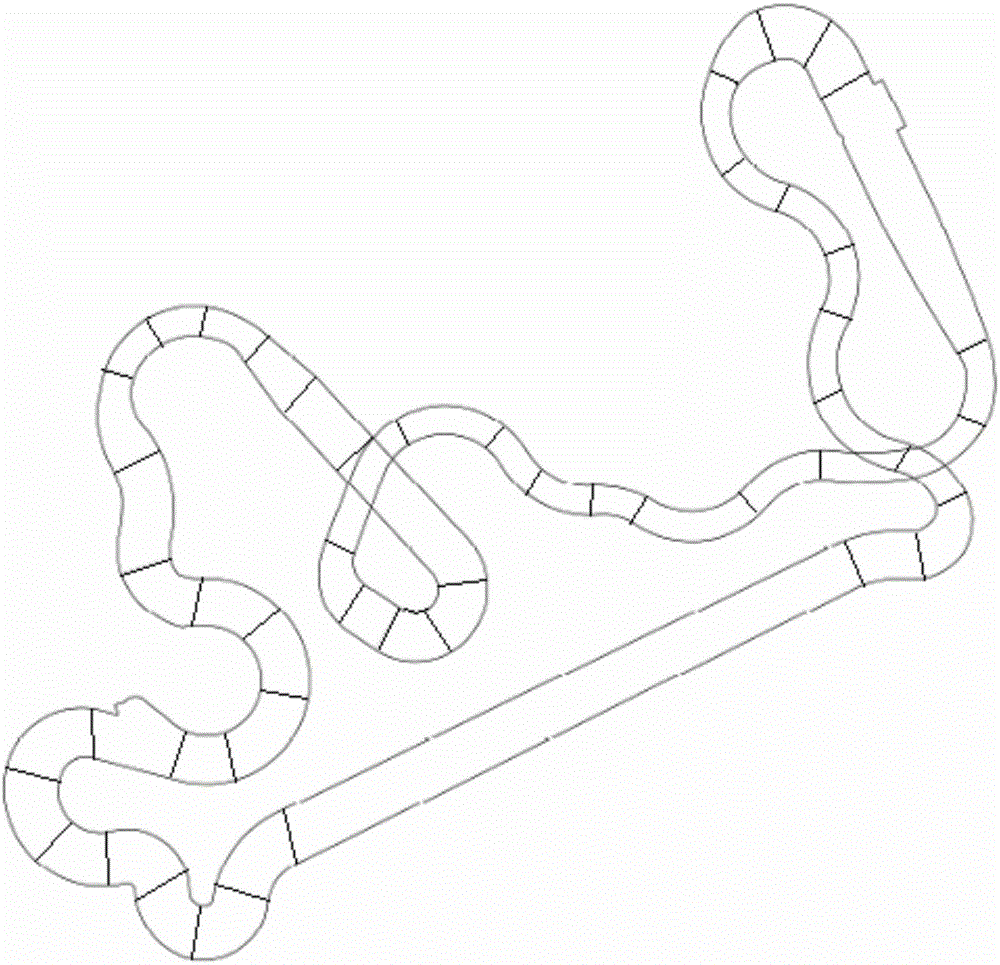

[0105] Such as figure 1 Shown is a space special-shaped water slide A designed by the designer. The special-shaped water slide includes a raft foundation 1, a support wall 2, a water slide bottom plate 3 and a water slide side wall 4 from bottom to top (see Figure 13 ), wherein the water slide floor 3 and the water slide side wall 4 form the water slide body structure. The special-shaped water slide A has a space curved surface structure. Along the extension direction of the special-shaped water slide, the water slide is divided into 54 sections for concrete pouring, and expansion joints are left between each section, such as figure 2 As shown, in order to adapt to the thermal expansion and contraction of the water slide under the climate temperature change.

[0106] In summary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com