Reed plywood and its processing method

A technology of rubber board and reed glue, which is applied in the direction of wood processing equipment, sugarcane machining, manufacturing tools, etc., can solve the problems of not being able to saw, plan and reuse, not being able to use building formwork, and long production cycle, etc., to achieve light weight, High production efficiency and brilliance on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

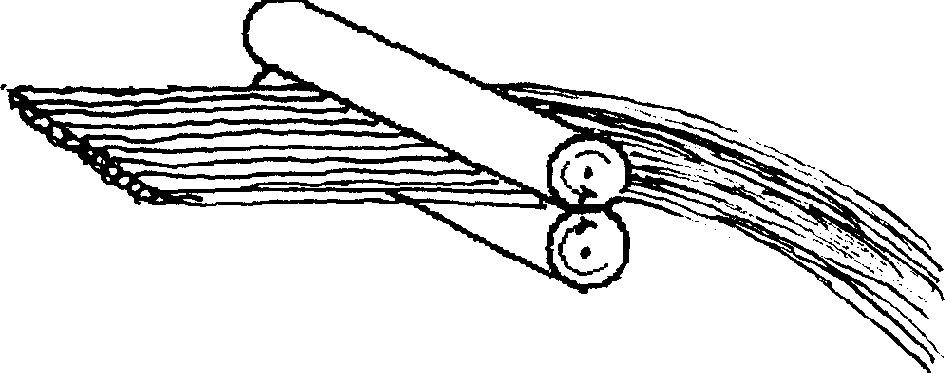

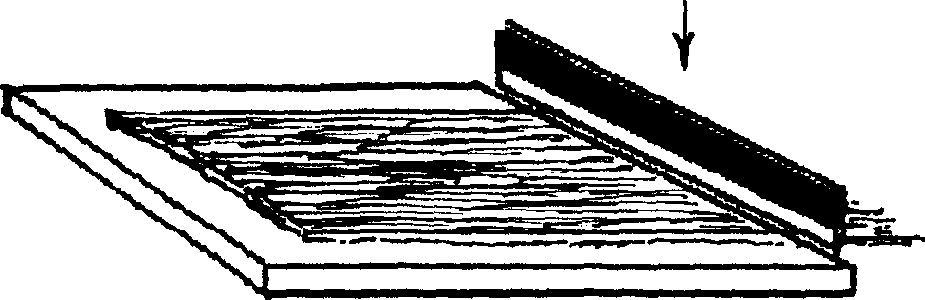

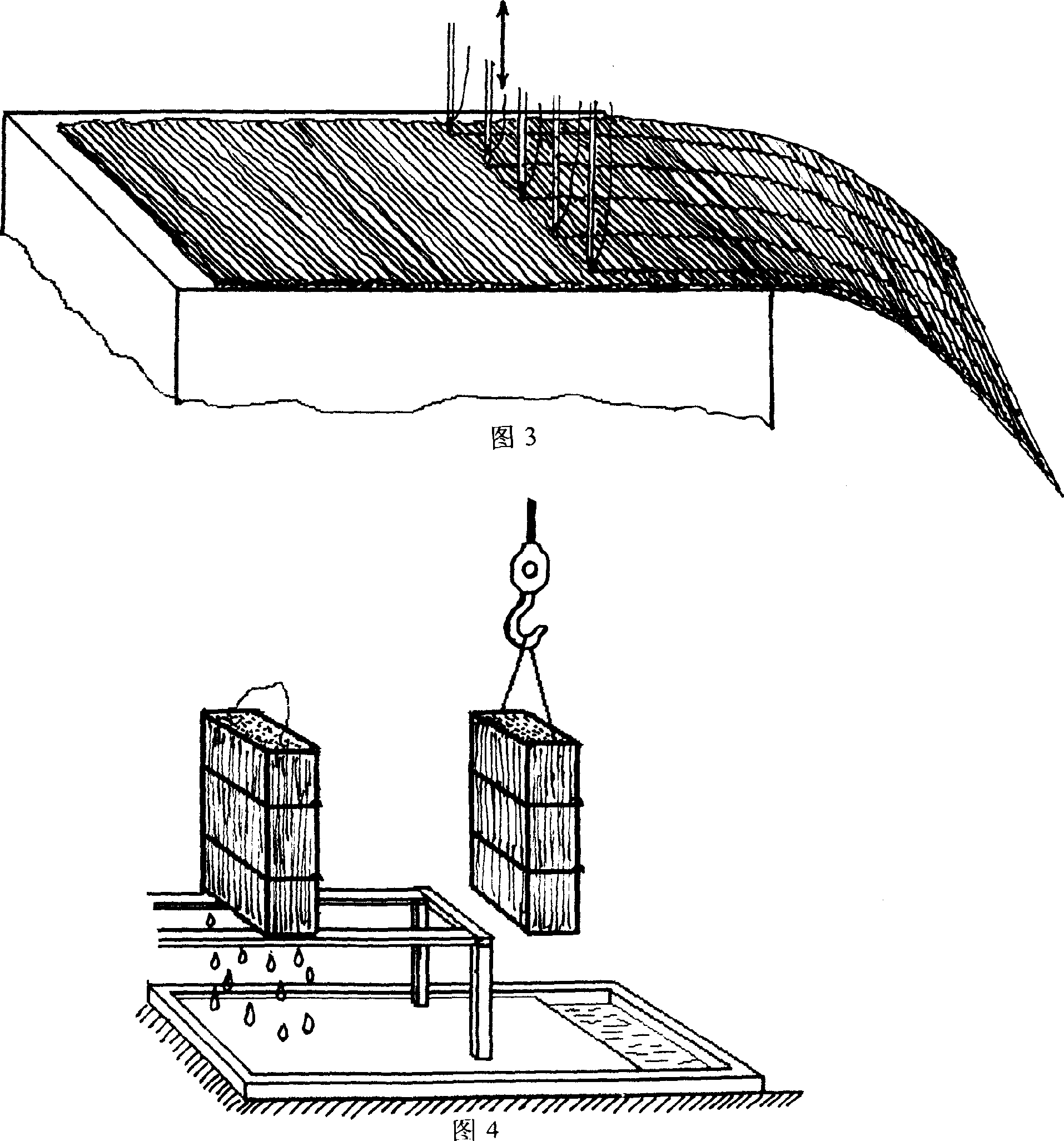

[0012] Embodiment 1, (a) longitudinally send the reed into useful material into the self-made special-purpose roll-type automatic rolling machine and carry out rolling, and the pressure range is at 1-2.5MPa, the reed blank that makes tubular reed form longitudinal rupture; Send the reed blank longitudinally into The mechanical cutting machine can cut according to two sizes of 1350mm and 2550mm respectively. (b) Send the cut 1350mm reed billet horizontally into the 1400mm wide self-made special automatic reed weaving machine, use the warp thread to weave according to the spacing of 100mm, and weave the reed curtain with a length of 2550mm × width 1350mm as the weft piece of the reed rubber board ; The cut 2550mm reed billet is also sent horizontally to the 2600mm wide self-made special automatic reed weaving machine, and the warp is used for weaving according to the spacing of 100mm, and the reed curtain with a length of 1350mm × width of 2550mm is woven as the warp sheet of the...

Embodiment 2

[0013] Embodiment 2, in step (b), use warp thread to weave weft sheet reed curtain and warp sheet reed curtain respectively by 300mm spacing; In step (f), hot pressing adopts hot press machine to send into 170 ℃ of high-pressure steam heating, at 900kg After pressing under pressure for 25 minutes, remove the heated high-pressure steam without depressurization, and send it into cooling water for cooling for 12 minutes. The rest are the same as example 1.

Embodiment 3

[0014] Embodiment 3, in step (b), use warp thread to weave weft sheet reed curtain and warp sheet reed curtain respectively by 500mm spacing; In step (f), hot-press setting adopts hot press to send into 185 ℃ of high-pressure steam heating, at 1200kg After pressing under pressure for 30 minutes, without decompression, remove the heated high-pressure steam, and send it into cooling water for cooling for 15 minutes. The rest are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com