A kind of device and preparation method of embossed quartz stone pattern plate

A technology of quartz stone and skin texture, applied in the field of texture processing, can solve the problems of poor decontamination ability, low pass rate, complicated process, etc., and achieve the effect of easy cleaning and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

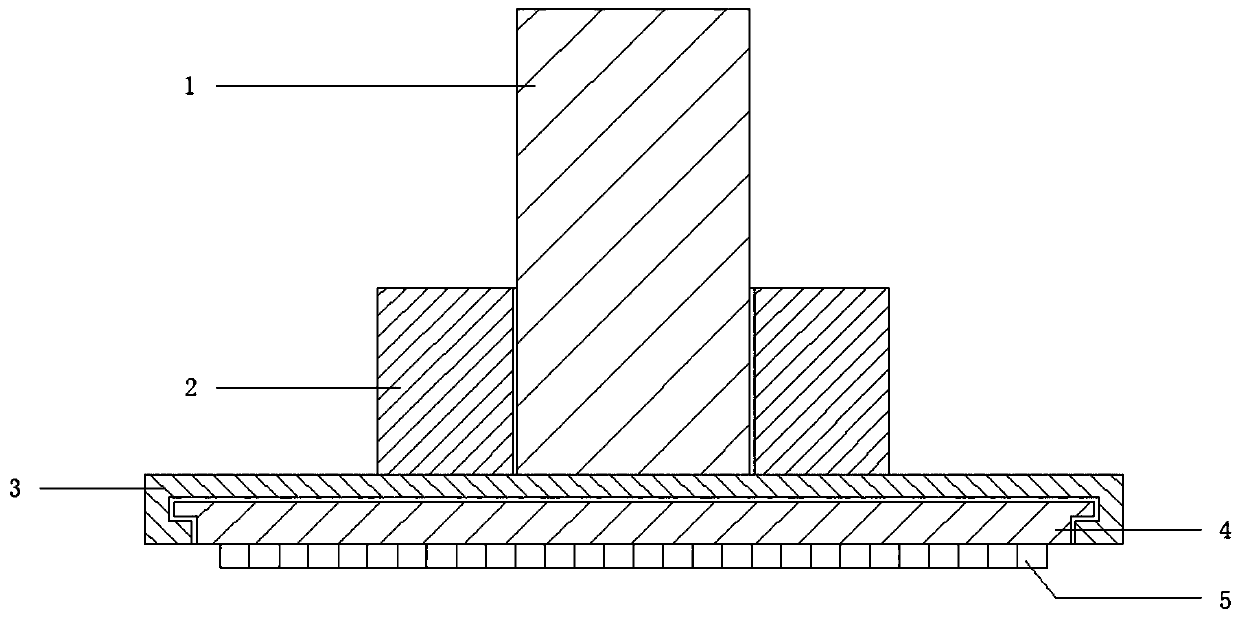

Image

Examples

Embodiment 1

[0029] In order to test the adhesion of liquid paraffin to polyethylene wax powder, the following experiment is now done.

[0030] (1) Take a quartz slab of 500×500×20mm, clean the surface of the quartz stone with diesel oil, and after cleaning, wipe the surface of the quartz stone with a dry cloth;

[0031] (2) Utilize the computer to design the texture, and then engrave the texture on the limestone board with an engraving machine. After the limestone board has carved the pattern, spray water-soluble amino-modified polydimethylsiloxane on the pattern. After natural air drying, the limestone The plate is inserted into the limit plate, and then the liquid paraffin is sprayed on the pattern, and the first embossing is carried out after the liquid paraffin is slightly dry;

[0032] (3) After the first embossing, spray the polyethylene wax powder evenly on the surface of the quartz stone, and after another embossing, use a soft brush to sweep the excess polyethylene wax powder int...

Embodiment 2

[0040] In order to test the effect of water-soluble amino-modified polydimethylsiloxane, the following experiment is now done.

[0041] (1) Take a quartz slab of 500×500×20mm, clean the surface of the quartz stone with diesel oil, and after cleaning, wipe the surface of the quartz stone with a dry cloth;

[0042] (2) Utilize the computer to design the texture, and then engrave the texture on the limestone board with an engraving machine. After the limestone board has carved the pattern, spray water-soluble amino-modified polydimethylsiloxane on the pattern. After natural air drying, the limestone The plate is inserted into the limit plate, and then the liquid paraffin is sprayed on the pattern, and the first embossing is carried out after the liquid paraffin is slightly dry;

[0043] (3) After the first embossing, spray the polyethylene wax powder evenly on the surface of the quartz stone, and after another embossing, use a soft brush to sweep the excess polyethylene wax powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com