Preparation method of silicon-based heteropolyacid doped magnetic composite membrane material

A heteropolyacid and composite membrane technology, applied in chemical instruments and methods, special compound water treatment, organic compound/hydride/coordination complex catalyst, etc., to achieve excellent Fenton performance, suitable for large-scale industrial production, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

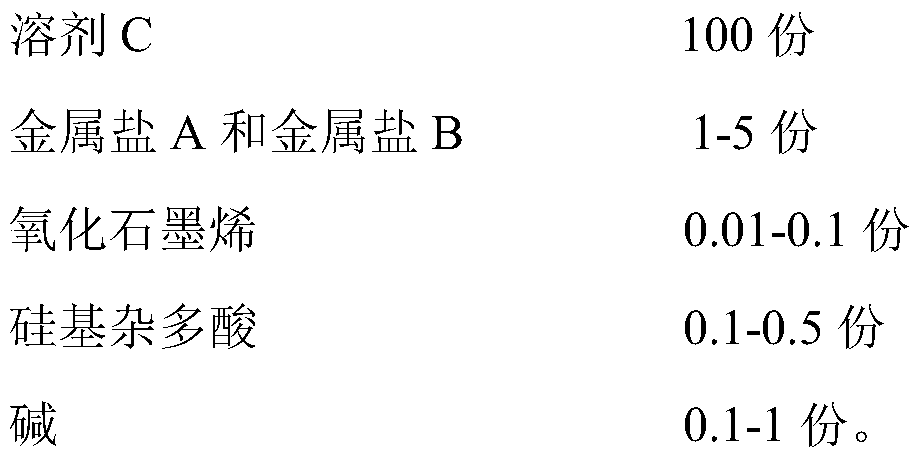

[0029] 0.3 g of ferric nitrate, 0.3 g of cobalt nitrate and 0.01 g of graphene oxide were added to 20 ml (22.68 g) of formamide and stirred for 60 minutes. Then add 0.05 g of silicotungstic heteropoly acid, and continue stirring for 60 minutes. Then add 0.1 part of sodium hydroxide and react in solvent at 90° C. for 80 minutes by solvothermal reaction. The product was filtered with suction and washed with ethanol and water. The filter membrane was dried at 100° C. for 15 hours to obtain a magnetic membrane composite material.

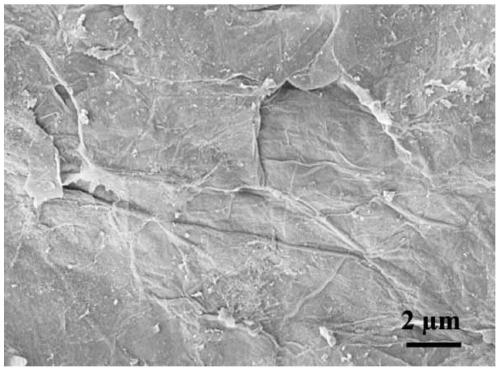

[0030] Depend on figure 1 The scanning electron microscope image shows that its morphology is film-like, composed of graphene oxide and inorganic nanoparticles, and the inorganic nanoparticles are cobalt ferrite magnetic particles doped with silicon-tungsten heteropolyacid. It can be seen from the figure that the nanoparticles are dispersed in the film layer formed by graphene oxide nanosheets.

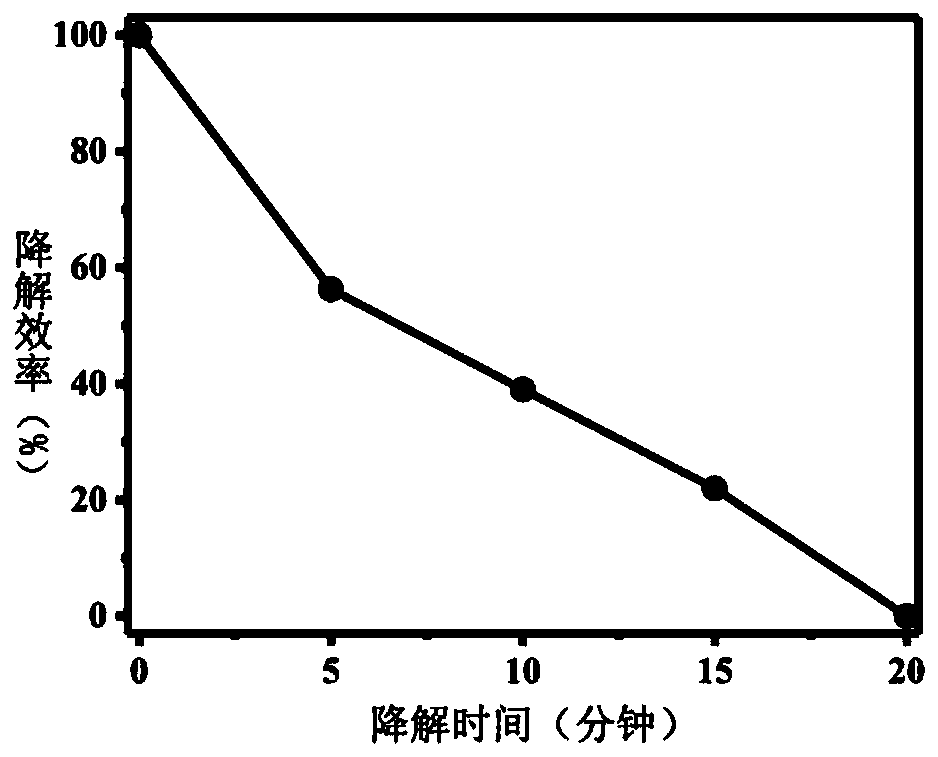

[0031] Add 0.05g silicon-based heteropolyacid-doped m...

Embodiment 2

[0033] As described in Example 1, the difference is that 0.3 g of nickel nitrate is added, and the silicon-based heteropolyacid-doped magnetic composite film can be completely chlorobenzene within 20 minutes.

Embodiment 3

[0035] As described in Example 1, the difference is that 0.5 gram of iron nitrate and 0.5 gram of cobalt nitrate are added, and the silicon-based heteropolyacid-doped magnetic composite film can be completely chlorobenzene within 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com