Preparation method for synthesizing graphene through biomass burning and application thereof

A combustion synthesis, biomass technology, applied in graphene, chemical instruments and methods, hybrid/electric double layer capacitor manufacturing and other directions, can solve the problems of high cost and complex graphene preparation process, achieve short reaction time, easy to batch Chemical production, process equipment and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The preparation method of biomass combustion synthesis graphene described in the present embodiment is as follows:

[0037] Weigh 1.5 parts of wood chips and 1 part of magnesium powder according to the mass parts and mix them evenly, place the mixed powder in a crucible combustion synthesis device, the combustion synthesis atmosphere is air, and the air pressure is controlled at 1.01Mpa. In the above atmosphere, use resistance wire to heat and ignite The powder mixed with sawdust and magnesium powder, after the combustion product is cooled to room temperature, the combustion product is pickled with 20% hydrochloric acid until the pH value of the pickling solution is less than 5 and remains unchanged, then the product is filtered and washed until the washing solution is medium properties, dried in a vacuum oven at 120°C for 12 hours.

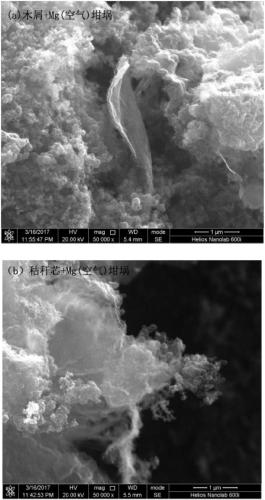

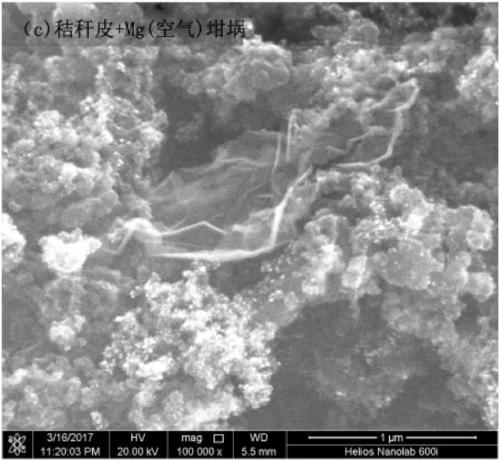

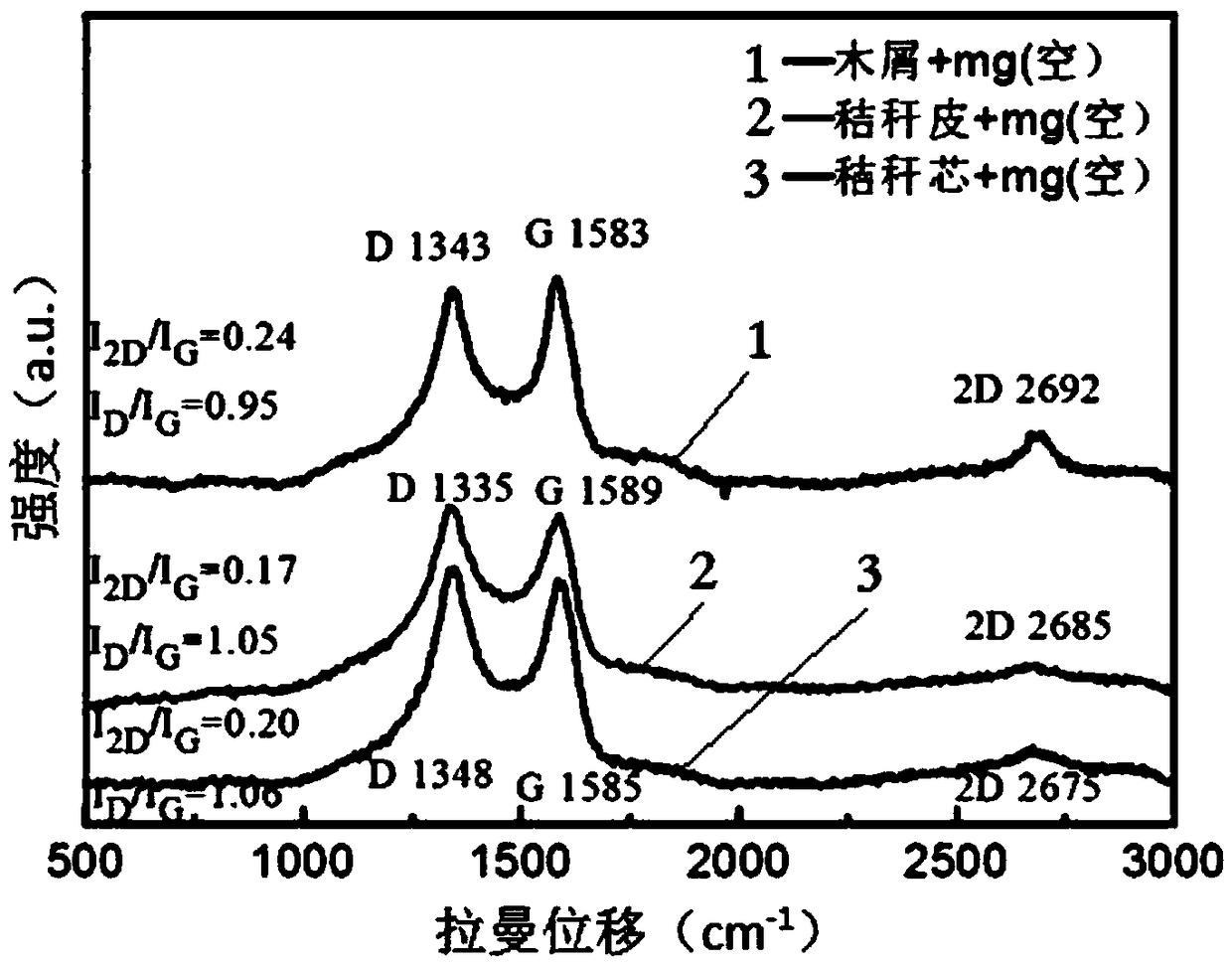

[0038] figure 1 It can be seen that the graphene powder prepared above is observed under a scanning electron microscope, a...

Embodiment 2

[0043] Embodiment 2: The preparation method of biomass combustion synthesis graphene described in the present embodiment is as follows:

[0044] Take 1.35 parts of straw core and 1 part of magnesium powder according to the number of parts by mass and mix them evenly, place the mixed powder in the combustion synthesis device, the combustion synthesis atmosphere is air, and the air pressure is controlled at 1.01Mpa. In the above atmosphere, use resistance wire to heat and ignite the straw The powder mixed with core and magnesium powder, after the combustion product is cooled to room temperature, the combustion product is pickled with 20% hydrochloric acid until the pH value of the pickling solution is less than 5 and remains unchanged, then the product is filtered and washed until the washing solution is neutral properties, dried in a vacuum oven at 120°C for 12 hours.

[0045] figure 1 It can be seen that the graphene powder prepared above is observed under a scanning electron...

Embodiment 3

[0050] Embodiment 3: The preparation method of biomass combustion synthesis graphene described in the present embodiment is as follows:

[0051] Take 1.5 parts of straw skin and 1 part of magnesium powder according to the mass parts and mix them evenly, place the mixed powder in the combustion synthesis device of the combustion synthesis device, the combustion synthesis atmosphere is air, and the air pressure is controlled at 1.01Mpa. Use resistance wire to heat and ignite the powder mixed with lignin and magnesium powder. After the combustion product is cooled to room temperature, pickle the combustion product with 20% hydrochloric acid until the pH value of the pickling solution is less than 5 and remains unchanged. Then filter and wash the product with water. , until the flushing solution is neutral, dry in a vacuum oven at 120°C for 12h.

[0052] figure 1 It can be seen that the graphene powder prepared above is observed under a scanning electron microscope, and the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com