Compressor system oil equalization control method and multi-compressor parallel system

A compressor system and control method technology, applied in compressors, compressors, irreversible cycle compressors, etc., can solve problems such as high process requirements, difficult piping, lack of phase angle control, etc., to solve complex manufacturing processes, Effect of Simplified Piping Design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

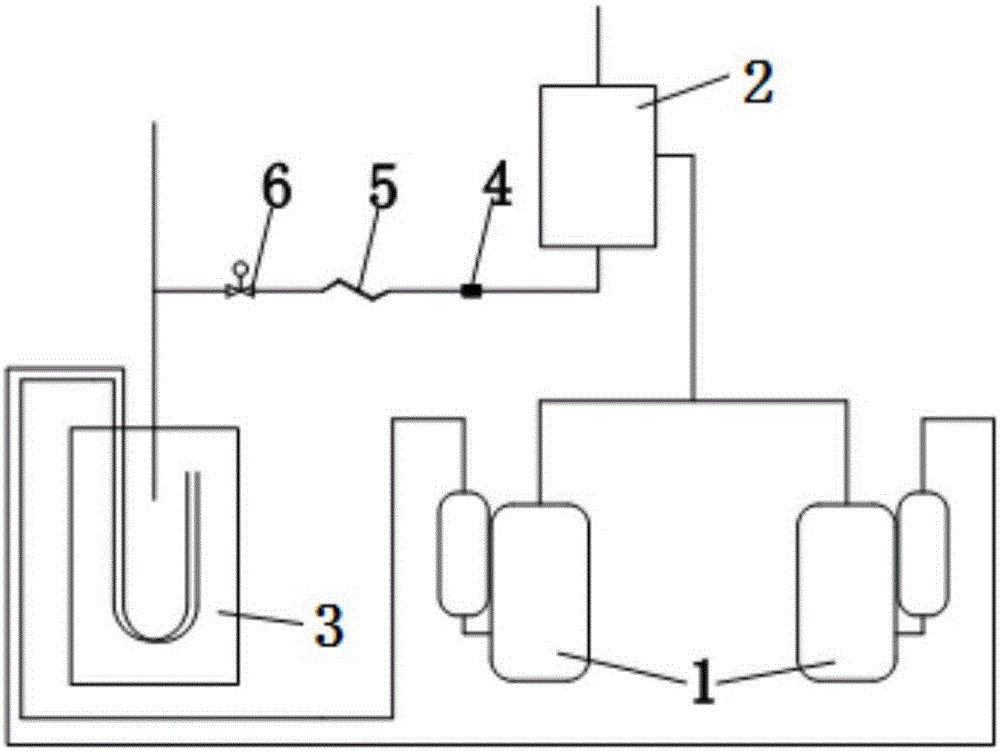

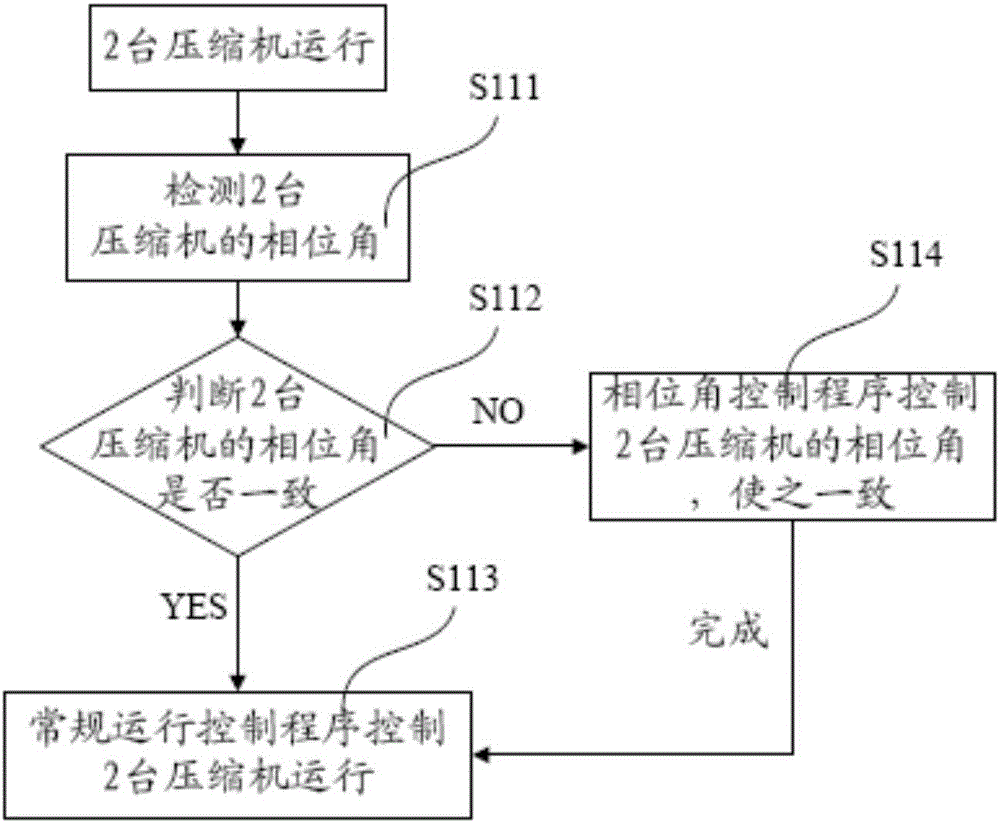

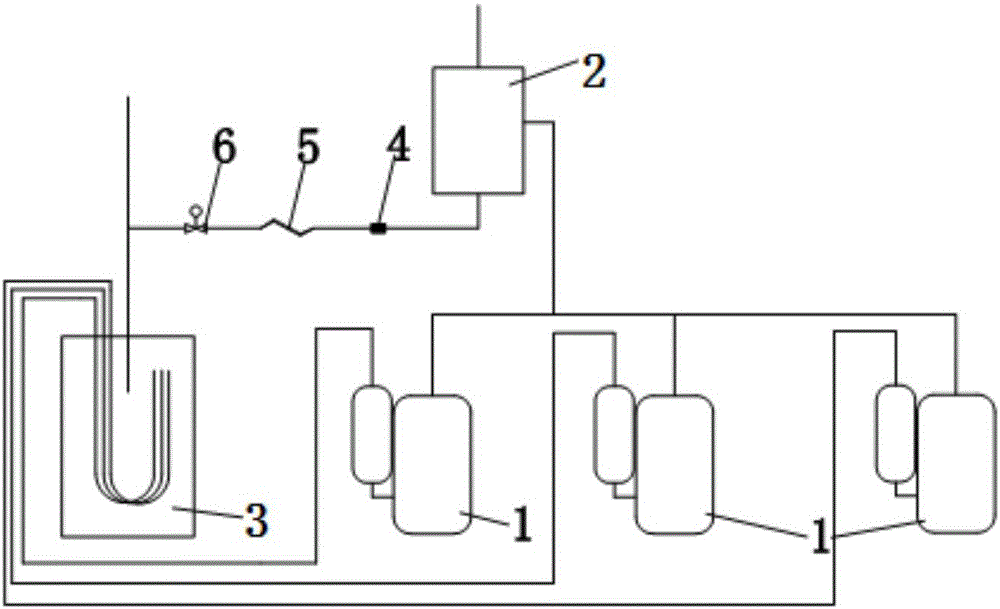

[0048] Embodiments of the compressor system oil equalization control method of the present invention, such as figure 2 , Figure 4 shown.

[0049] The oil equalization control method of the compressor system of the present invention comprises the following steps:

[0050] Set up N rotary compressors connected in parallel;

[0051] Start the N1 compressors 1 in the N parallel-connected rotary compressors to run simultaneously;

[0052] Detecting the phase angles of the motor rotors of the N1 compressors;

[0053] Determine whether the phase angles of the motor rotors of the N1 compressors are consistent; if they are consistent, run the routine operation control program to control the operation of the N1 compressors 1; if not, adjust the phase angles of the motor rotors of the N1 compressors so that After the phase angles are consistent, run the routine operation control program to control the operation of the N1 compressors 1;

[0054] N and N1 are integers greater than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com