High-contrast organic light-emitting device (OLED) with band-pass filter film and top-emitted green ray

A band-pass filtering, high-contrast technology, applied in electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of process limit cost and yield, and achieve complex device preparation process, low efficiency loss and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

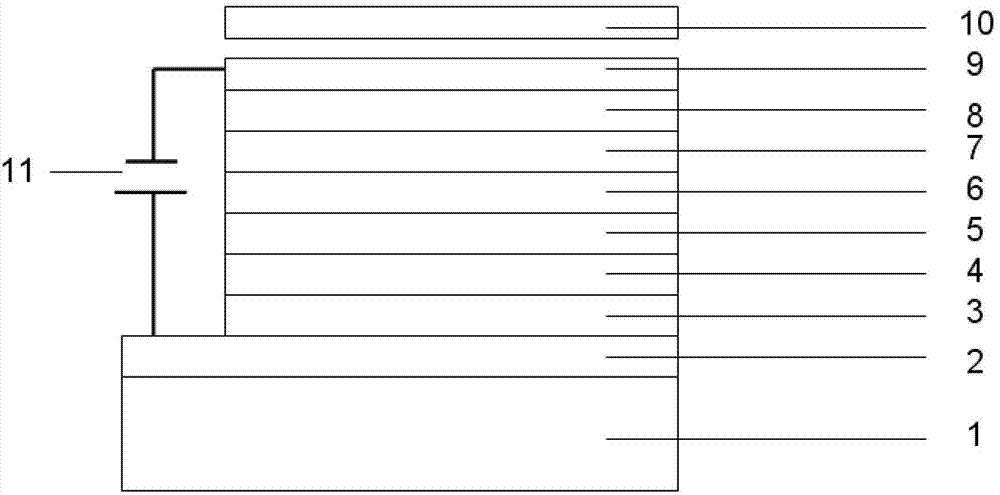

[0025] Prepared structure as Si / SiO 2 / Al / m-MTDATA:MoO 3 / m-MTDATA / Ir(ppz) 3 / CBP: Ir(ppy) 3 / BPhen / LiF / Al / Ag / band-pass filter film top-emitting green organic electroluminescent device, the device is prepared in a multi-source organic molecule vapor deposition system, and the detailed preparation process is as follows:

[0026] [1] The silicon substrate covered with silicon dioxide with a thickness of 340 nm was scrubbed repeatedly with acetone and ethanol cotton balls in sequence, then ultrasonicated with acetone, ethanol, and deionized water in sequence, and then dried.

[0027][2] Place the treated substrate in the metal evaporation system. The vacuum chamber of the system contains 4 metal evaporation sources and every two evaporation sources share a set of control systems, which can simultaneously carry out the deposition of two metal materials. Evaporation, in order to ensure the uniformity of evaporation and facilitate the evaporation of metal materials, the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com