Food packaging adhesive and preparation method thereof,

A food packaging and adhesive technology, applied in the direction of monocarboxylic acid ester copolymer adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problems of complex preparation process, low adhesive strength and high preparation cost , to achieve the effects of low preparation cost, fast bonding speed, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

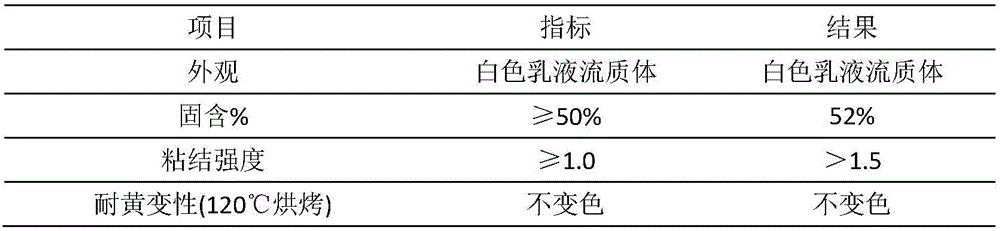

Image

Examples

Embodiment 1

[0047] In parts by weight, add 450 parts of deionized water and 30 parts of polyvinyl alcohol into the reactor successively, heat up and stir, and after the polyvinyl alcohol is completely dissolved, cool down to 80°C; Add 100 parts of butyl ester and 100 parts of methyl methacrylate into the drop tank and mix evenly to obtain mixed monomers; under stirring conditions, add 5 parts of γ-aminopropyltriethoxysilane, NP 8 parts of -40, 8 parts of OP-10, 6 parts of ethylenediaminetetraacetic acid disodium salt and 2 parts of silicone oil, after the dispersion is uniform, start to drop the mixed monomer, and add dropwise 0.15wt% of the total amount of the mixed monomer The mass fraction of ammonium persulfate solution is 0.3% ammonium persulfate aqueous solution, and the dropwise addition is completed within 4 hours; after the dropwise addition, the temperature is raised to 90°C for aging for 50 minutes, and then the temperature is lowered to 40°C, and 2 parts of Kasone are added, st...

Embodiment 2

[0049] In parts by weight, sequentially add 450 parts of deionized water and 50 parts of polyvinyl alcohol into the reactor, heat up and stir, and after the polyvinyl alcohol is completely dissolved, cool down to 80°C; Add 80 parts of butyl ester and 120 parts of methyl methacrylate into the drip tank and mix evenly to obtain mixed monomers; under stirring conditions, add γ-(methacryloyloxy)propyl trimethoxy 8 parts of base silane, 15 parts of NP-40, 15 parts of OP-10, 3 parts of tetrasodium edetate and 2 parts of silicone oil. The mass fraction of 0.15wt% is 0.5% potassium persulfate aqueous solution, and the dropwise addition is completed within 3 hours; after the dropwise addition is completed, the temperature is raised to 95 ° C for 60 min, and then the temperature is lowered to 45 ° C, and 5 parts of Casson are added, stirred and mixed After uniformity, the material is discharged, filtered and packaged to obtain the finished product.

Embodiment 3

[0051]In parts by weight, sequentially add 500 parts of deionized water and 15 parts of polyvinyl alcohol into the reactor, heat up and stir, and after the polyvinyl alcohol is completely dissolved, cool down to 75°C; Add 80 parts of butyl ester and 120 parts of methyl methacrylate into the dripping tank and mix evenly to obtain mixed monomers; under stirring conditions, add 2 parts of vinyltrimethoxysilane and 3 parts of NP-40 in sequence into the above reactor , 3 parts of OP-10, 8 parts of trisodium hydroxyethyl ethylenediamine triacetate and 2 parts of silicone oil, after the dispersion is uniform, start to drop the mixed monomer, and drop the mass of 0.2wt% of the total amount of the mixed monomer The fraction is 0.1% potassium persulfate aqueous solution, and the dropwise addition is completed within 3 hours; after the dropwise addition, the temperature is raised to 85°C for aging for 40 minutes, and then the temperature is lowered to 35°C, and 2 parts of Casson are added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com