Array substrate, backlight module, display panel, display device and preparation method

An array substrate and column direction technology, which is applied in the fields of display devices and preparation, display panels, backlight modules, and array substrates, can solve the problems of complex array substrate preparation process and high production cost, and achieve saving of masks and preparation processes, The effect of simplifying the preparation process and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, rather than to limit the present invention. In addition, it should be noted that, for the convenience of description, only some parts related to the present invention are shown in the drawings but not all structures.

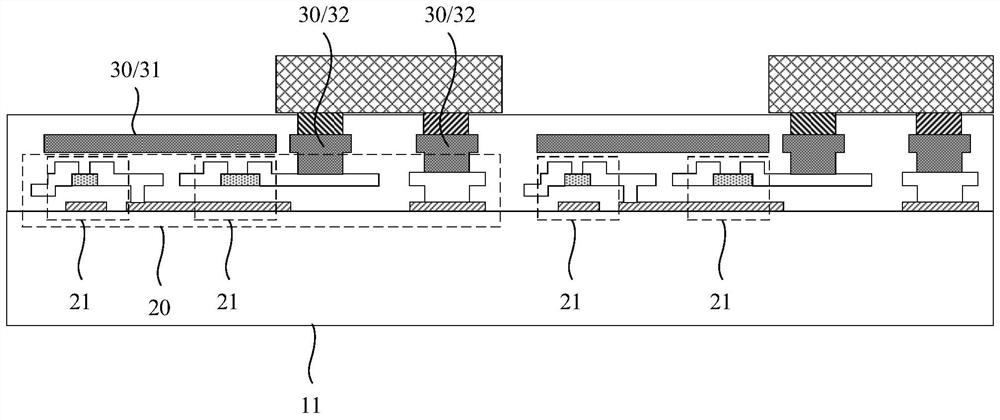

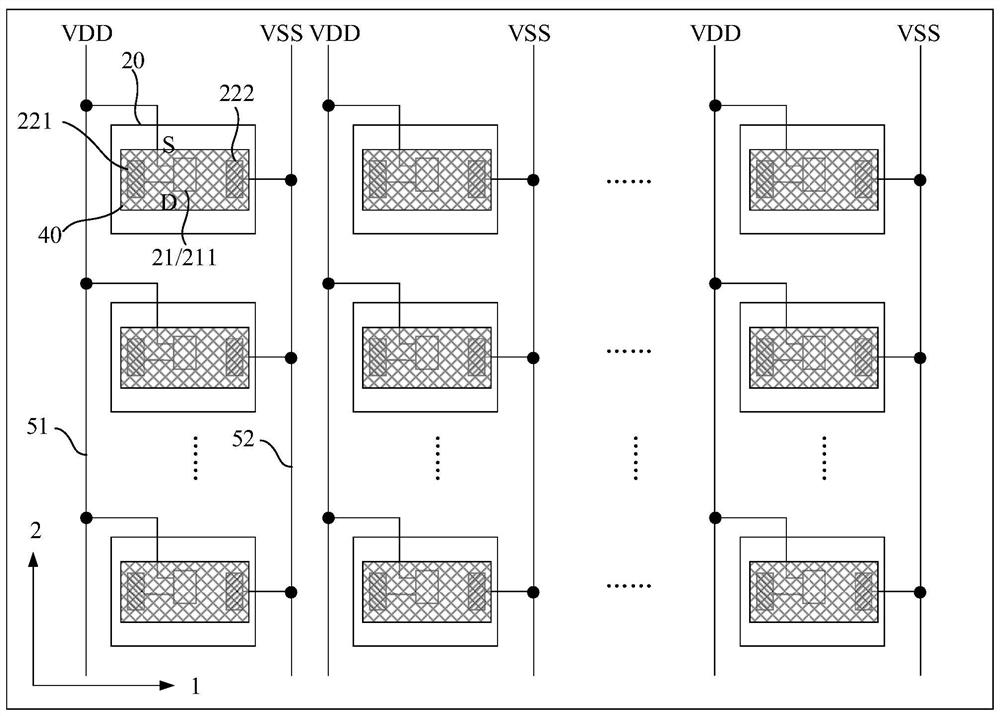

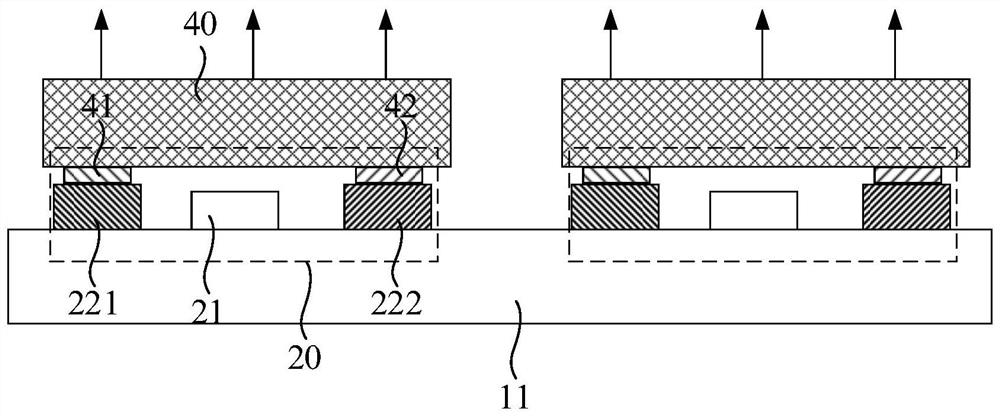

[0043] As mentioned in the background technology section, in the existing panel preparation process, in order to prevent the thin film transistor from being affected by light, it is generally necessary to set up a light-shielding layer for light-shielding. figure 1 is a schematic diagram of the structure of the existing array substrate, refer to figure 1, in the array substrate, the drive unit 20 provided on the base substrate 11 includes a thin film transistor 21, and the side of the thin film transistor 21 away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com