Mold-duplicating preparation process for mineral casting

A technology of mineral casting and preparation process, which is applied in the field of preparation process of mineral casting mold copying, and can solve the problems of complex manufacturing process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention should be included in the protection of the present invention. within range.

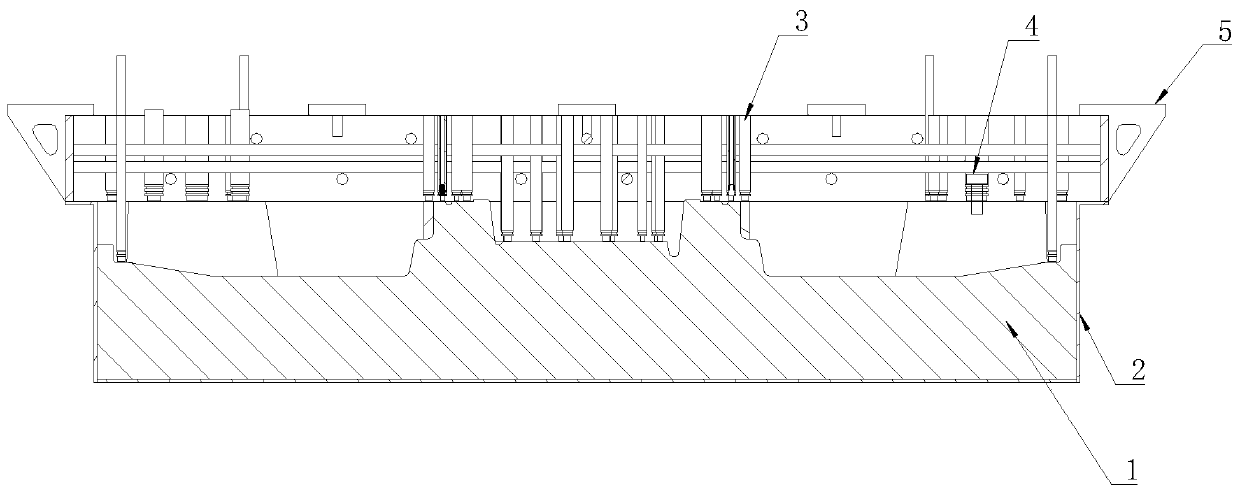

[0023] Based on the elaboration of the above background technology, such as figure 1 As shown, the embodiment of the present invention proposes a preparation process for copying of mineral casting molds, including the product 1 that needs to be turned over, the original product mold coaming 3 and the overturning coaming 5, wherein the following products are the required turning over The product of the mold is the product prepared by the original product mold, or the original product; the original product mold coaming is the mold frame required for the preparation of the product.

[0024] Embodiments of the present invention use a preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com