A kind of preparation method of modified metal powder

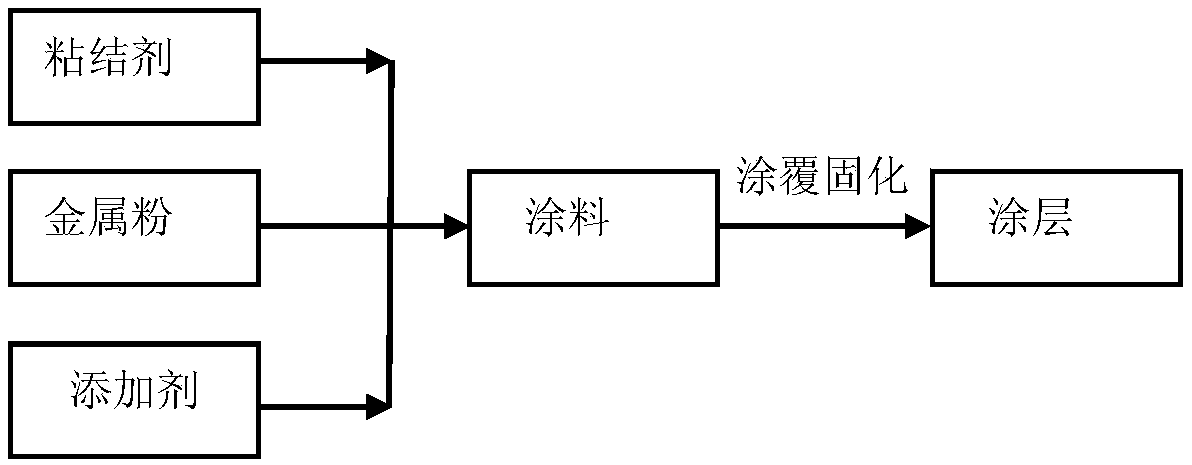

A metal powder and modification technology, which is applied in the direction of metal processing equipment, metal material coating technology, powder coating, etc., can solve the problems such as complex preparation process, and achieve the goal of solving complex preparation process, improving corrosion resistance, and improving adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

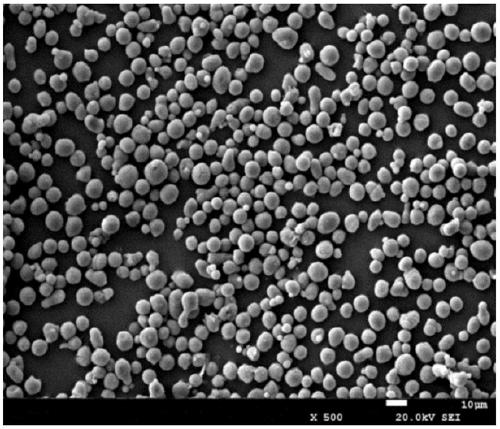

[0050] In yet another typical embodiment of the present application, a method for preparing modified metal powder is provided. The preparation method includes: mixing the above-mentioned metal powder modifying liquid and metal powder, making the metal powder modifying liquid and metal The powder reacts at room temperature (around 25°C) to 98°C to obtain modified metal powder

[0051] Utilize the metal powder modifying solution of the present application to modify the metal powder under the above mild conditions, the reaction time between the metal powder modifying solution and the metal powder is relatively short, making the preparation method of the modified metal powder of the present application relatively simple , Easy to control. If the temperature of the above reaction is too high, the metal powder will easily become brittle, and if the temperature is too low, the reaction will be too slow.

[0052] And in the modification process, phosphoric acid provides an acidic env...

Embodiment 1

[0065] The composition of the metal powder modifying solution is shown in Table 1.

[0066] The process of metal powder treatment and coating preparation is as follows:

[0067] Add the above-mentioned phosphoric acid, chromium trioxide, sodium fluoride, and deionized water into the stirred tank, heat it in a water bath to 60°C, and stir at a speed of 600r / min for 30min to obtain a metal powder modification solution;

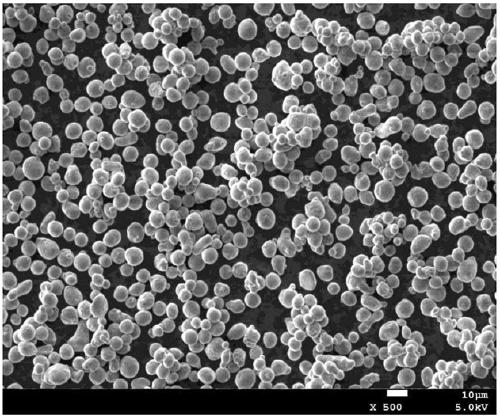

[0068] Slowly add 10kg of spherical aluminum powder to the above stirring tank, maintain the water bath temperature at 60°C, stir at a rate of 600r / min for 10min, stop stirring, and obtain the post-reaction system;

[0069] After the centrifugal separation reaction, the system was left to stand still to obtain aluminum powder precipitation, the supernatant was poured out, the modified aluminum powder was washed with deionized water for 3 times, and dried for later use;

[0070] Prepare the modified aluminum powder after drying with phosphate binder, additives a...

Embodiment 2 to 6

[0072] The implementation process is the same as in Example 1, and the composition of the metal powder modification solution is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com