Standard knot device and tower crane

A tower crane and standard section technology, applied in cranes, mechanical equipment, engine components, etc., can solve problems such as the development of a complex reinforcement plate manufacturing process, and achieve the effect of being beneficial to the design and solving the complex manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

[0035] The standard section device according to the present invention will be described below with reference to the accompanying drawings.

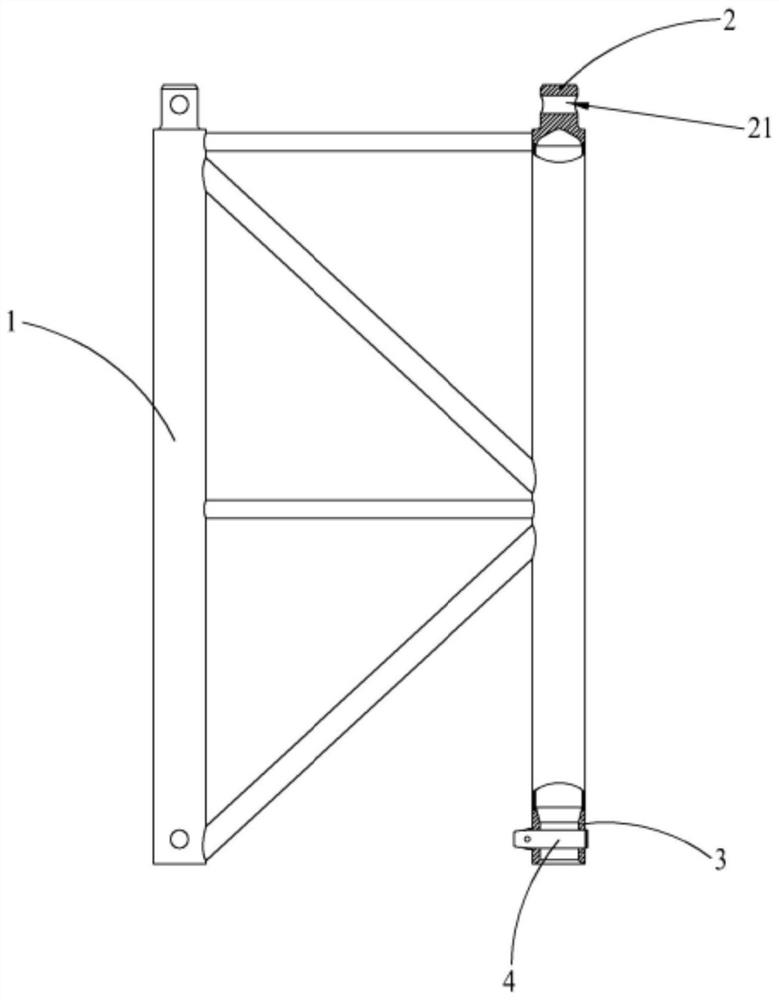

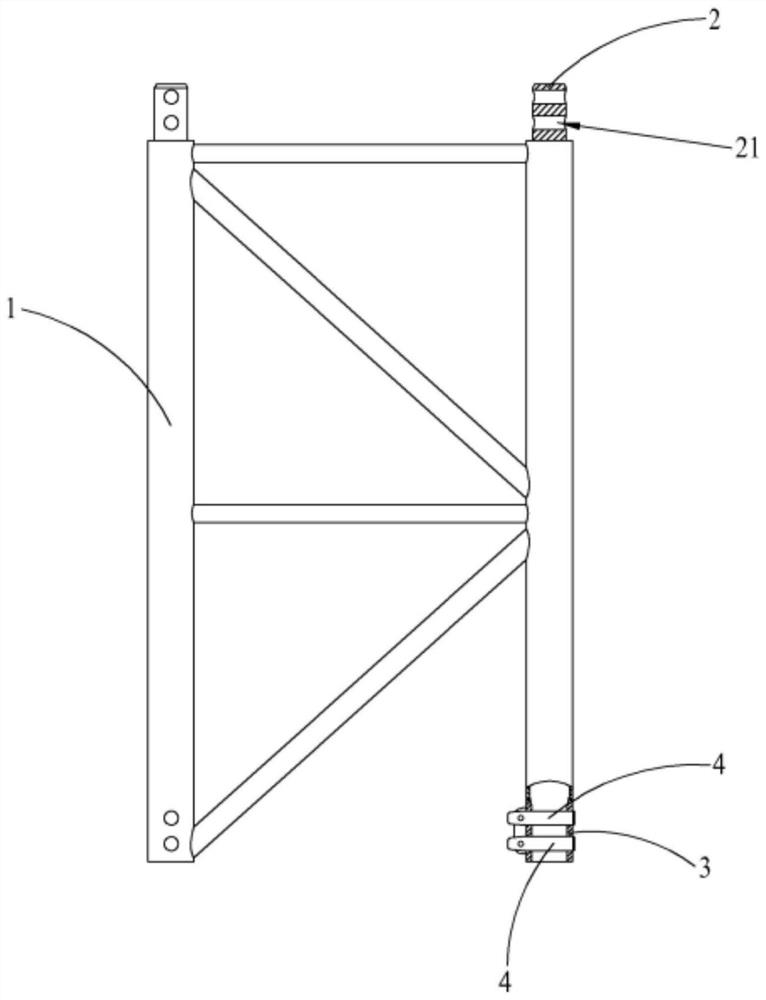

[0036] like figure 1 and figure 2 As shown, a standard section device is provided in an embodiment of the present invention, wherein the standard section device includes:

[0037] The main chord body 1 is set as a hollow tube;

[0038] The male joint 2 is arranged at the first end of the main chord body 1, and the male joint 2 is provided with a radially through first pin hole 21;

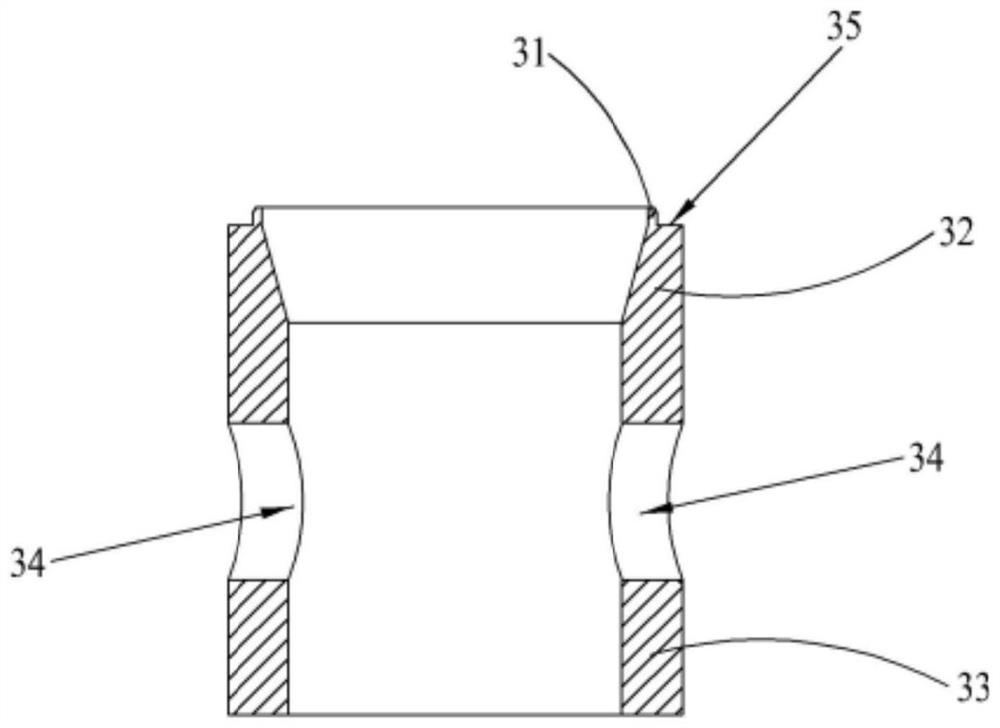

[0039] The female joint 3 is set as a hollow circular tube and connected to the second end of the main chord body 1, the outer diameter of the female joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com