Lead-free glass powder for preparing solar cell silver paste and application of lead-free glass powder

A technology of solar cells and lead-free glass powder, applied in the field of solar cell materials, can solve problems such as environmental pollution threats, achieve low softening point, and improve photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

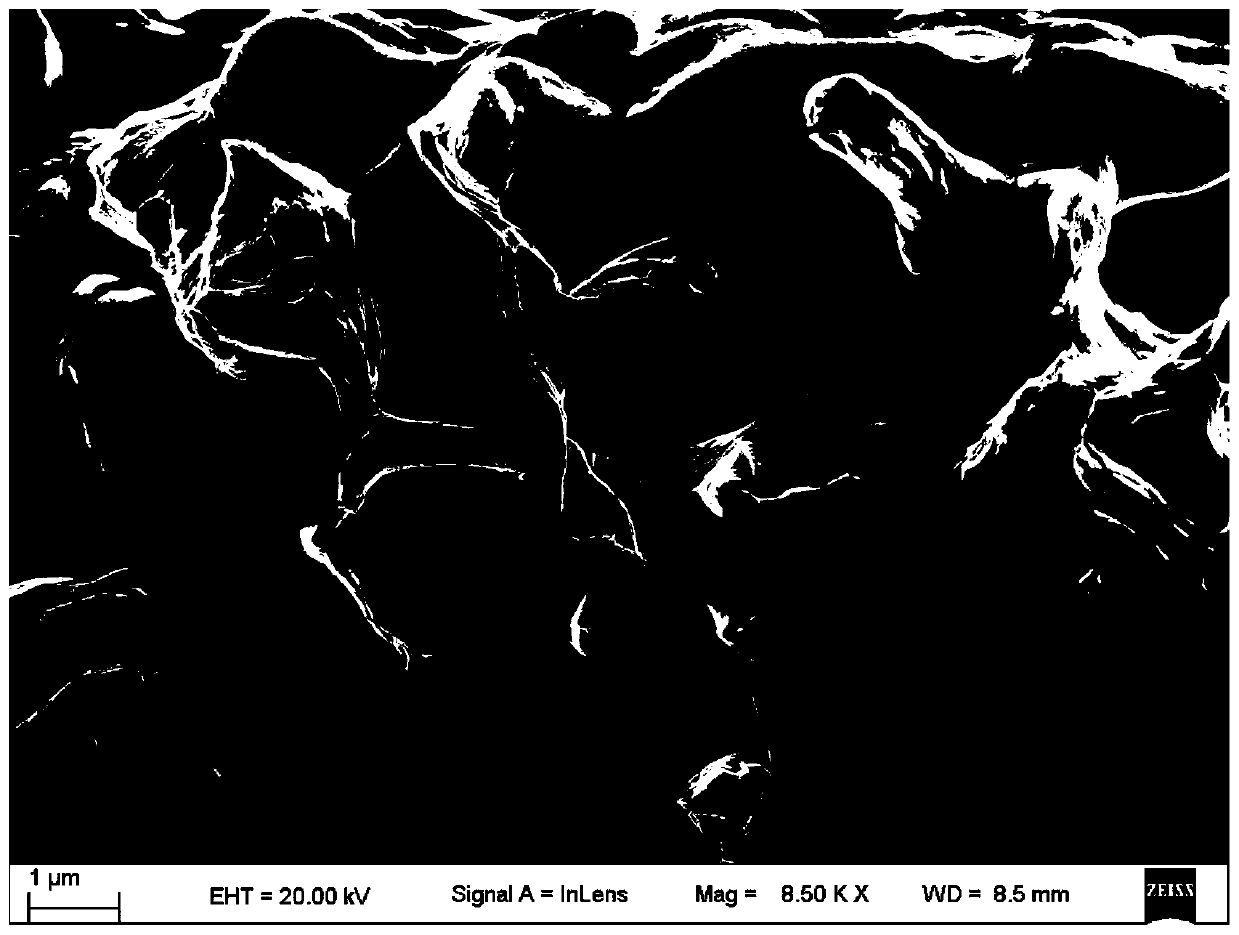

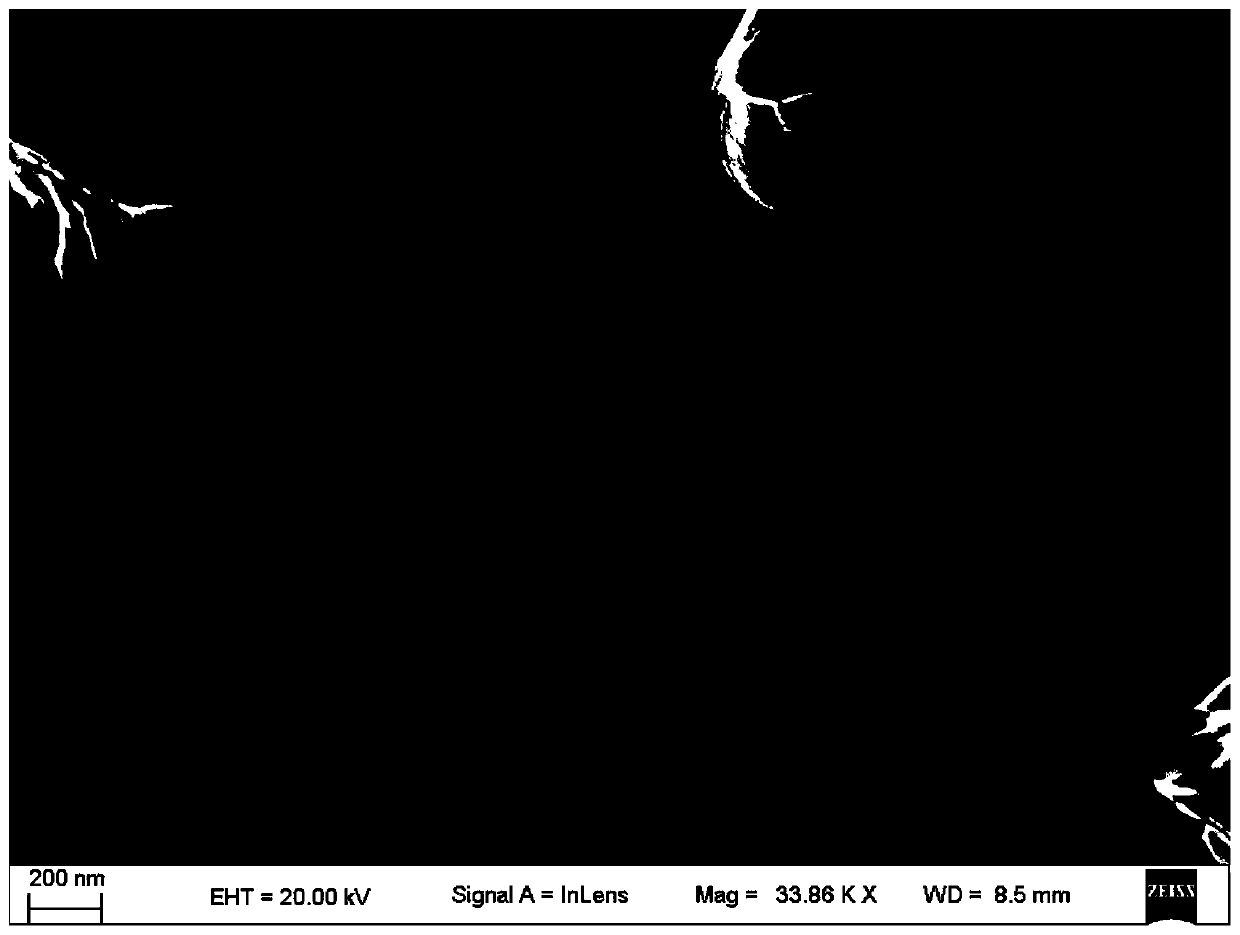

Image

Examples

Embodiment 1

[0040] In this example, different precious metal elements, lead-free metal oxides and non-metal oxides are used to prepare lead-free glass powder; in addition, as a comparison, this example also designs conventional lead-containing glass powder as a comparative test; the glass powder formula is shown in the table 1; Among them, the 1~32# test is the lead-free glass powder of this example, and the 33# test is the lead-containing glass powder for comparison.

[0041] Table 1 glass powder formula (weight percent %)

[0042]

[0043]

[0044] "Precious metal element" in Table 1 refers to the weight percentage of the corresponding precious metal elemental substance, for example, "Ru10" means that the metal Ru is used in an amount of 10 wt%; the rest of the components are also in weight percentage.

[0045] Weigh each raw material according to the weight percentage in Table 1, mix it to make 100g of the mixture, mix it evenly, put it into an alumina crucible, cover it, put the...

Embodiment 2

[0053] In this example, the lead-free glass frit of test 6# in Table 1 of Example 1 was used for the test to prepare solar battery silver paste, and the dosage ratio of silver powder, organic phase and glass frit was analyzed. The solar cell silver paste formula is shown in Table 3.

[0054] The silver paste formula (% by weight %) of different proportions of solar cell

[0055] test silver powder The organic phase glass powder 1 70% 15% 15% 2 80% 10% 10% 3 90% 5% 5% 4 90% 8% 2% 5 90% 9.5% 0.5%

[0056] Each component was weighed according to the weight ratio in Table 3, and the total weight was 100 g. After mixing, it was ground with a three-roll mill to make the solar cell silver paste of this example.

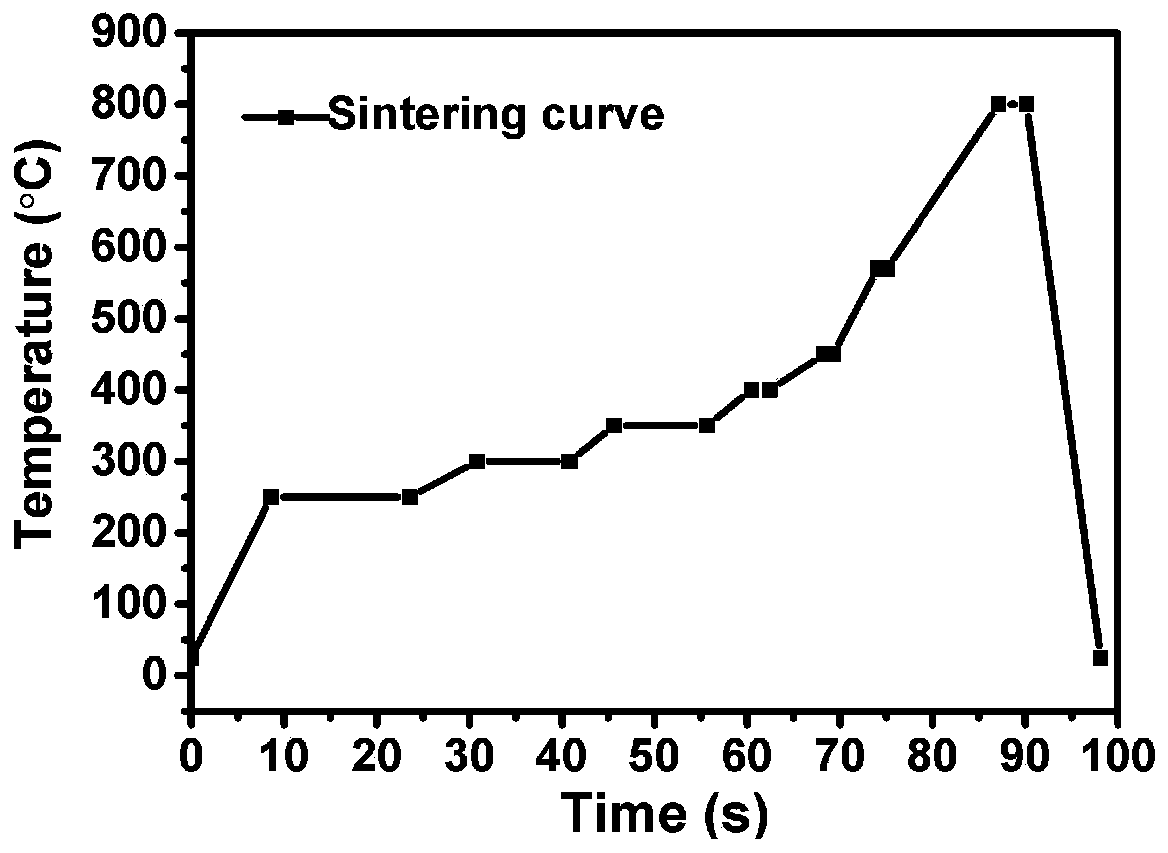

[0057] The prepared solar cell silver paste is screen-printed into a solar cell, and then sintered in a special solar cell sintering furnace. The sintering conditions are as follows: image 3 As shown, and then use the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com