Modified SiCf/SiC composite material and preparation method thereof

A composite material and modification technology, which is applied in the field of modified SiCf/SiC composite materials and their preparation, can solve the problems of long time consumption, easy softening, poor mechanical properties and oxidation resistance of sintered composite materials, and achieves a simplified production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

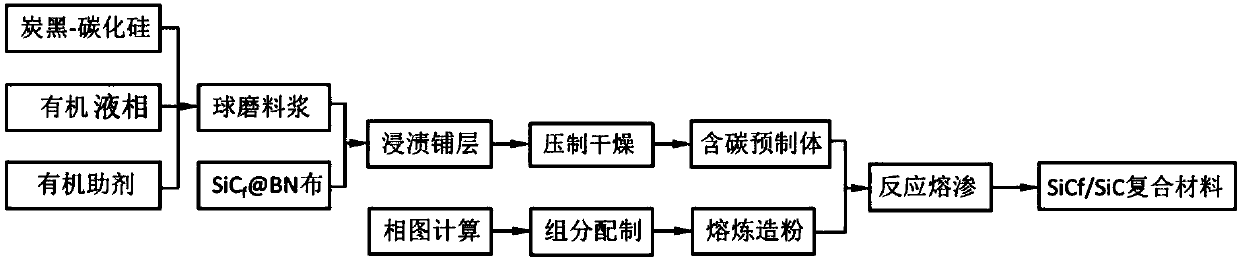

[0029] Such as figure 1 As shown, one embodiment of the present invention proposes a modified SiC f / SiC composite material preparation method, it comprises:

[0030] 1) Using carbon black and silicon carbide powder as the solid phase, mixing with the liquid phase, adding additives, ball milling and mixing for 24-48 hours, vacuum ultrasonic degassing, to obtain impregnation slurry;

[0031] Wherein, the volume content of the solid phase in the impregnation slurry is 32.5-38.5%; the mass ratio of silicon carbide and carbon black in the solid phase is 6-8:1.

[0032] The liquid phase includes ethanol and methyl ethyl ketone; the mass ratio of ethanol and methyl ethyl ketone is 1.05-1.35:1.

[0033] Auxiliaries include dispersants, binders and plasticizers. The dispersion agent is polyvinylpyrrolidone and triethyl phosphate; the binder is polyvinyl butyral; the plasticizer is dimethyl phthalate. In the dispersant, polyvinylpyrrolidone is 6-12% of the mass of carbon black, tri...

Embodiment 1

[0039] A modified SiC proposed by an embodiment of the present invention f / SiC composite material preparation method, it comprises:

[0040] 1) Use ethanol and methyl ethyl ketone as the liquid phase, carbon black and silicon carbide powder as the solid phase, add polyvinylpyrrolidone and triethyl phosphate as the dispersant, add polyvinyl butyraldehyde as the binder, and add phthalate Dimethyl formate is used as a plasticizer, mixed by ball milling for 48 hours, vacuum ultrasonic degassing, and impregnation slurry is obtained; wherein, the solid phase volume content is 38%, and the mass ratio of silicon carbide to carbon black is 6:1; polyethylene in the dispersant Pyrrolidone is 6% of the carbon black mass, triethyl phosphate is 2.2% of the silicon carbide mass; the binder is 3.2% of the solid phase mass, and the plasticizer is 60% of the binder mass;

[0041] 2) Put the silicon carbide fiber containing the boron nitride interface phase and the impregnation slurry in a vacuu...

Embodiment 2

[0046] A modified SiC proposed by an embodiment of the present invention f / SiC composite material preparation method, it comprises:

[0047] 1) Use ethanol and methyl ethyl ketone as the liquid phase, carbon black and silicon carbide powder as the solid phase, add polyvinylpyrrolidone and triethyl phosphate as the dispersant, add polyvinyl butyraldehyde as the binder, and add phthalate Dimethyl formate is used as a plasticizer, and the ball mill is mixed for 48 hours with vacuum ultrasonic degassing to obtain an impregnation slurry; wherein, the solid phase volume content is 32.5%, and the mass ratio of silicon carbide to carbon black is 8:1; polyvinylpyrrolidone in the dispersant 12% of the mass of carbon black, triethyl phosphate is 3% of the mass of silicon carbide; the binder is 4.2% of the mass of the solid phase, and the plasticizer is 80% of the mass of the binder;

[0048] 2) Put the silicon carbide fiber containing the boron nitride interface phase and the impregnat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com