Low-temperature composite high-heat-conductivity ceramic material and preparation method thereof

A technology of high thermal conductivity ceramics and ceramic materials, which is applied in the field of low-temperature composite high thermal conductivity ceramic materials and its preparation, can solve the problems of material uniformity limitation, lower material high temperature performance, high processing cost, etc., and achieve uniform, stable and compact physical and chemical properties As well as the effect of strength improvement and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The composition of the ceramic material is: 60 parts of modified polysiloxane, 39 parts by weight of mixed powder of aluminum oxide and aluminum nitride, and 1 part of titanate coupling agent.

[0047] The mixed powder of alumina and aluminum nitride has a particle size of 1-3 μm and a purity of over 99%.

[0048] The titanate coupling agent is selected from isopropyl three (dioctyl pyrophosphoryl acyloxy), isopropyl trioleate acyloxy titanate, tetraisopropyl two (dioctyl phosphite acyloxy) oxy) titanate, etc. In this embodiment, isopropyl trioleate acyloxy titanate is selected.

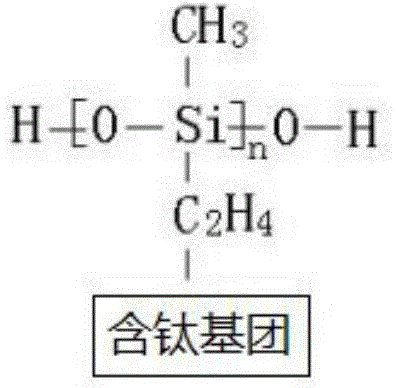

[0049] Modified polysiloxane can be prepared by the following preparation method, but this method is only for example and not as a limitation of the present invention:

[0050] 1. Stir and mix the aromatic solvent, alkyl ester solvent and soft water, then add the chlorosilane mixture and titanate and keep stirring, and keep the temperature at room temperature.

[0051] 2. Washing after sepa...

Embodiment 2

[0062] The composition of the ceramic material is as follows in parts by weight: 60 parts of modified polysiloxane, 30 parts of mixed powder of alumina and aluminum nitride, 1 part of silane coupling agent, 1 part of titanium oxide, 1 part of silicon dioxide, 1 part of mica portion composition.

[0063] The mixed powder of alumina and aluminum nitride has a particle size of 1-3 μm and a purity of over 99%. Wherein the silane coupling agent is KH560. Titanium oxide, silicon dioxide, and mica are ceramic performance additives. The ceramic performance additives described in this embodiment can be one or more of the above-mentioned materials, and the particle size is controlled at the nanometer level, such as within 10 nanometers, and the purity is 99%. %above.

[0064] The preparation process of ceramic materials is as follows:

[0065] 1. Put the mixed powder of alumina and aluminum nitride into a low-temperature nitrogen-protected drying oven for drying at 170°C, keep it war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com