A method for continuously preparing fluorescent carbon nanoparticles

A technology of carbon nanoparticles and fluorescence, applied in the direction of nano-carbon, nanotechnology, chemical instruments and methods, etc., can solve the problems of easy storage of corncobs, huge supply, etc., achieve uniform and stable physical and chemical properties, and simple preparation methods , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

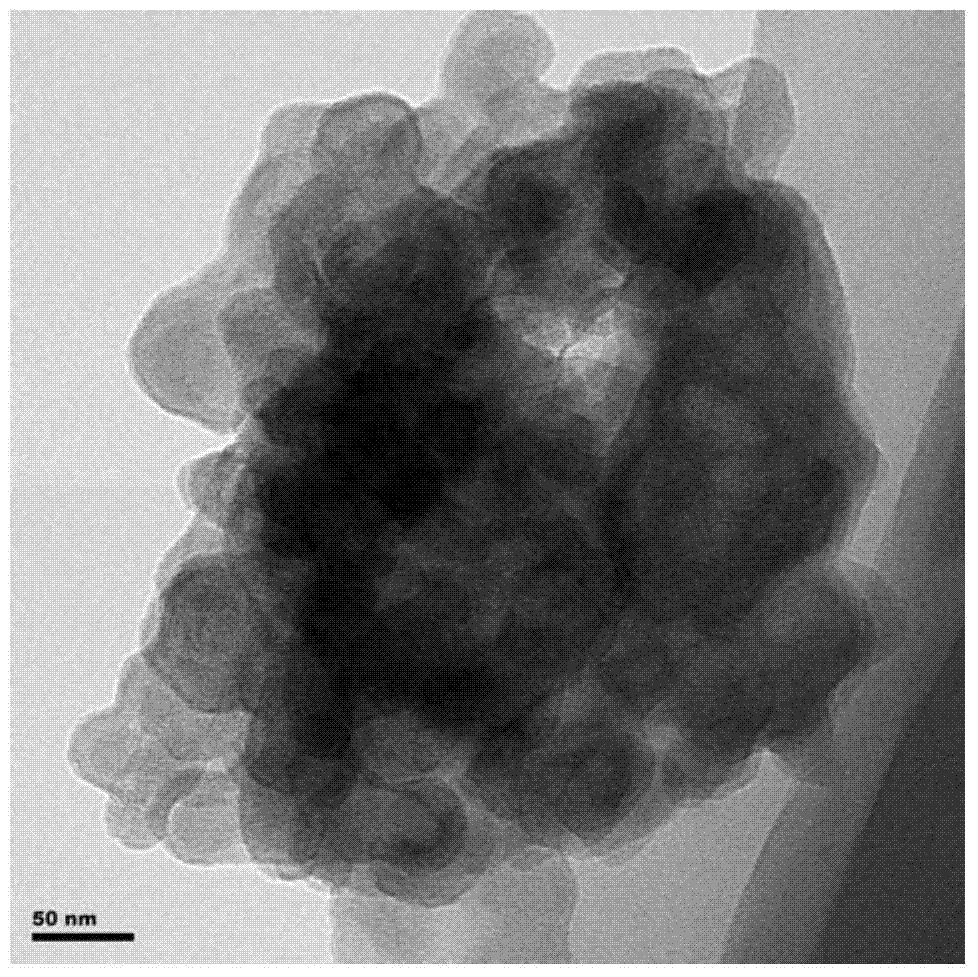

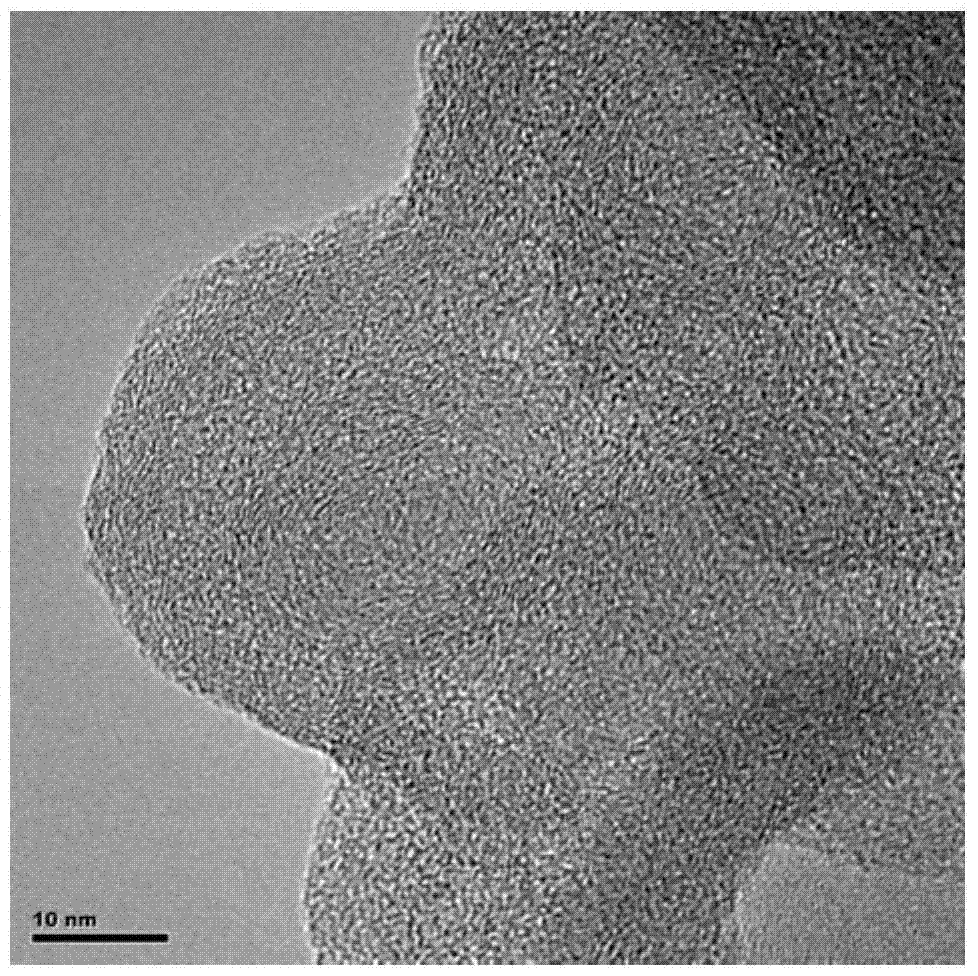

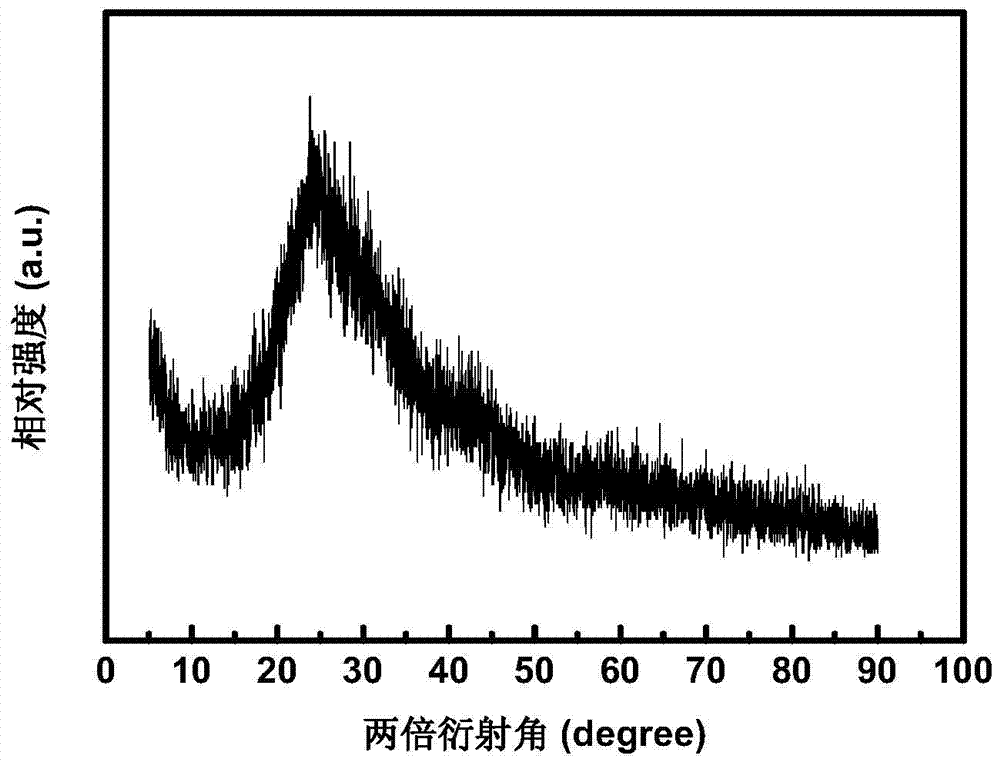

Embodiment 1

[0035]Take the corncobs and bake them in an oven at 60°C for 24 hours. The baked corn cobs are put into a quartz tube furnace and calcined at high temperature under the protection of an argon atmosphere. (Parameters: 5°C / min to raise the temperature to 1000°C, and keep it at 1000°C for 4 hours and then cool naturally.) During the whole reaction process, the outlet pipe was passed into a glass bottle filled with ultrapure water to receive the gas from the tube furnace. Outgoing product. After the reaction was completed, the product was put into a dialysis bag with a molecular weight cut-off of 300 Daltons and dialyzed for 7 days to obtain the final aqueous solution of carbon nanoparticles. After evaporating with a rotary evaporator, the brown powder is taken out to be carbon nanoparticles.

Embodiment 2

[0037] Take the corncobs and bake them in an oven at 60°C for 24 hours. The baked corn cobs are put into a quartz tube furnace and calcined at high temperature under the protection of an argon atmosphere. (Parameters: 10°C / min heating up to 1200°C, and cooling naturally after 10 hours of heat preservation at 1200°C.) During the entire reaction process, the gas outlet pipe was passed into a glass bottle filled with ultrapure water to receive the gas from the tube furnace. Outgoing product. Finally, dichloromethane was mixed with an equal solution volume of the aqueous solution of carbon nanoparticles. The mixture was shaken back and forth in a separatory funnel for 10 minutes. After the solution is static and stratified, the aqueous solution containing carbon nanoparticles in the lower layer is taken. Repeat the above operation 15 times. After evaporating with a rotary evaporator, the brown powder is taken out to be carbon nanoparticles.

Embodiment 3

[0039] Take the corncobs and bake them in an oven at 60°C for 24 hours. The baked corn cobs are put into a quartz tube furnace and calcined at high temperature under the protection of an argon atmosphere. (Parameters: 5°C / min heating up to 1100°C, and cooling naturally after 6 hours at 1100°C). Outgoing product. After the reaction is finished, centrifuge for 4 hours in a centrifuge with a centrifugal speed greater than 20,000 rpm. Take out the centrifuge tube and pour off the supernatant. Pour 50ml of ultrapure water into a centrifuge tube and put it into an ultrasonic cleaner for 30 minutes of sonication. Repeat the above centrifugation step 10 times. Finally, the brown precipitate in the lower layer was put into a vacuum freezer and freeze-dried at -40°C for 24 hours. The finally obtained brown powder is carbon nanoparticle powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com