Preparation method of waterproof fireproof ceramic silicon rubber composite tape

A technology of ceramic silicone rubber and composite tape, which is applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., can solve the problems of easy pulverization and falling off, limited manufacturing length, high production cost, etc., and improve water resistance Fire and vibration resistance, improvement of compactness and strength, effect of improvement of compactness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Preparation of High Strength Silicone Compound

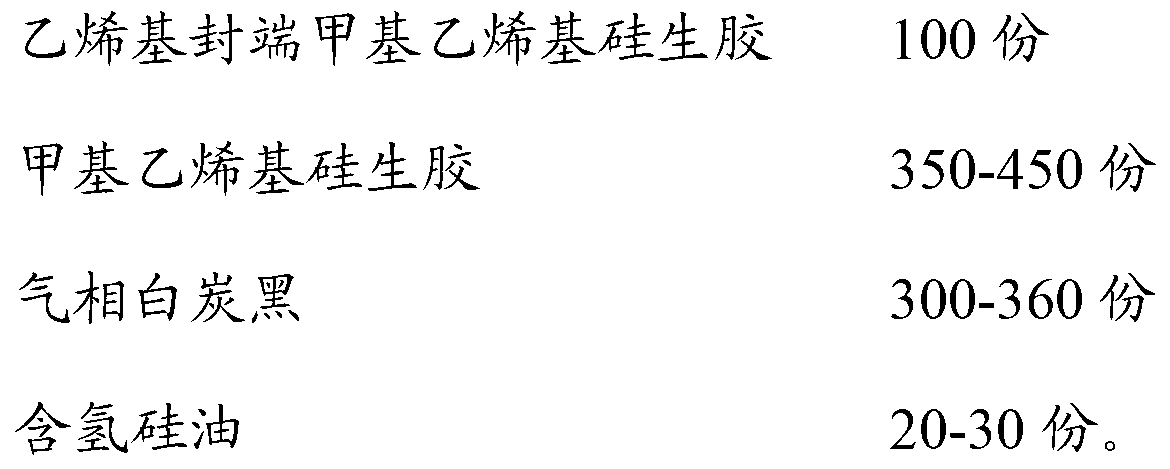

[0040] Weigh 120 g of vinyl-terminated methyl vinyl silicone raw rubber with a vinyl content of 0.28% (mass) and a molecular weight of 700,000, and 265 g of methyl vinyl silicone rubber with a vinyl content of 0.06% (mass) and a molecular weight of 800,000 215g of methyl vinyl silicone rubber with a vinyl content of 0.50% (mass) and a molecular weight of 600,000, 30g of hydrogen-containing silicone oil with a hydrogen content of 0.1% (mass) and a viscosity of 100mPa·s, and 96g of fumed silica in a kneader After kneading into a group, add 100g of fumed silica in three times each time, after mixing them all into a group, raise the temperature to 90°C and continue kneading for 2.5h, then raise the temperature to 150°C to vacuumize (vacuum degree 0.08-0.09MPa) and mix Refined for 0.5 hour, took out and cooled naturally to obtain high-strength silicone rubber compound.

[0041] A vulcanizing agent was added to the high-streng...

example 2

[0043] Preparation of Composite Ceramic Powder

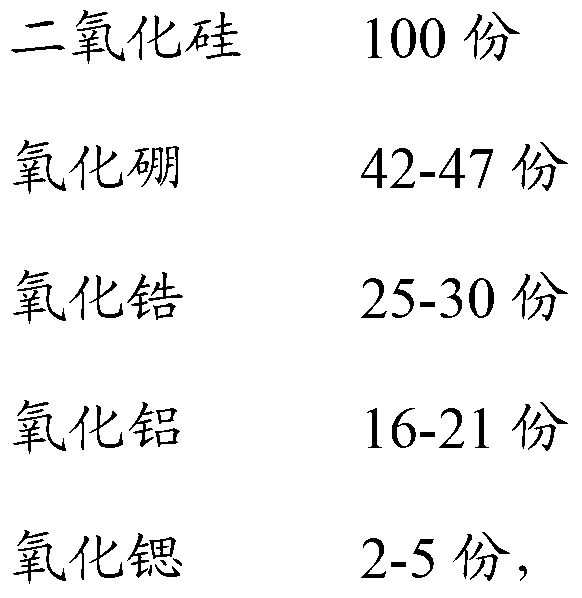

[0044] The composite ceramic powder in this embodiment includes ceramic green body material and ceramic glaze body material. Weigh 100g of silicon dioxide, 45g of boron oxide, 30g of zirconium oxide, 20g of aluminum oxide and 3g of strontium oxide, and mix them to obtain 198g of ceramic green body material.

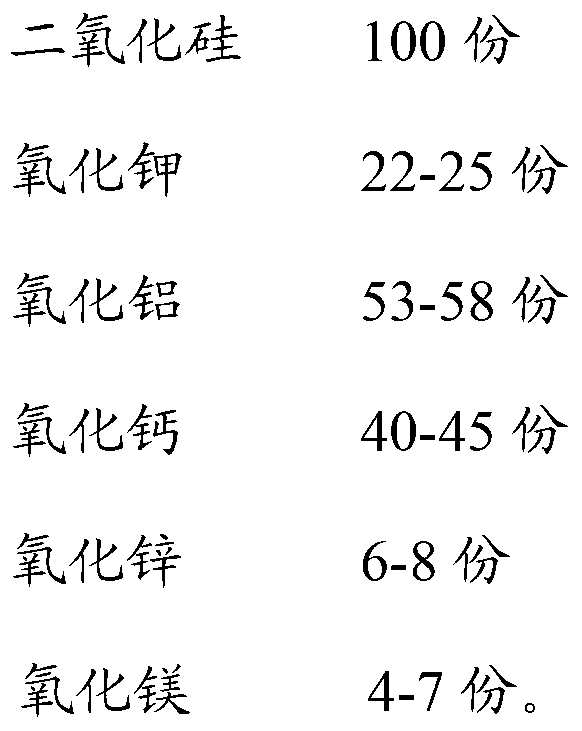

[0045] Weigh 8g ZnO, add 42g CaO, add 20g talcum powder (containing MgO 31.8%, SiO 2 63.2%, both are mass fractions), equivalent to adding 6g MgO and 13g SiO 2 ; Add 134g potassium feldspar (containing SiO 2 64.7%, Al 2 o 3 18.4%, K 2 O 16.9%, both are mass fractions), equivalent to adding 23g K 2 O, 87g SiO 2 , 24g Al 2 o 3 , then SiO in talc powder and potassium feldspar 2 The total mass is 100g, then add 31g Al 2 o 3 , so that Al 2 o 3 The total mass of the potash feldspar reaches 55g, and the potassium feldspar is ground into powder and then added, and after mixing uniformly, 235g of ceramic glaze body mat...

example 3

[0048] Treatment of glass cloth

[0049] Weigh 110g of silicon acrylic emulsion with a silicon content of 8% (mass) and a solid content of 45% (mass), dilute it with 890g of water, and use the diluted silicon acrylic emulsion to treat the glass cloth by dip coating, and then place it in an oven for 80 Bake at ℃ for 8 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com