Cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy and production method of permanent magnet comprising same

A liquid phase alloy, rare earth permanent magnet technology, used in magnetic liquids, magnetic objects, inductance/transformer/magnet manufacturing, etc., can solve the requirements of difficult to achieve comprehensive magnetic properties, low coercivity, rich in lanthanum and cerium magnets. Rare earth phase structure changes and other problems, to improve the ability to remove exchange coupling, coercive force, grain boundary phase smooth and straight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Through the preparation method of the present invention, adding Ce 30 -Nd 50 -Fe 20 High-performance Ce-Nd-Fe-B magnets are prepared from the rapid-setting belt of low-melting liquid phase alloy.

[0044] Step 1: According to the mass percentage (Nd 0.5 Ce 0.5 ) 30 Fe 69 B 1 Preparation of raw materials.

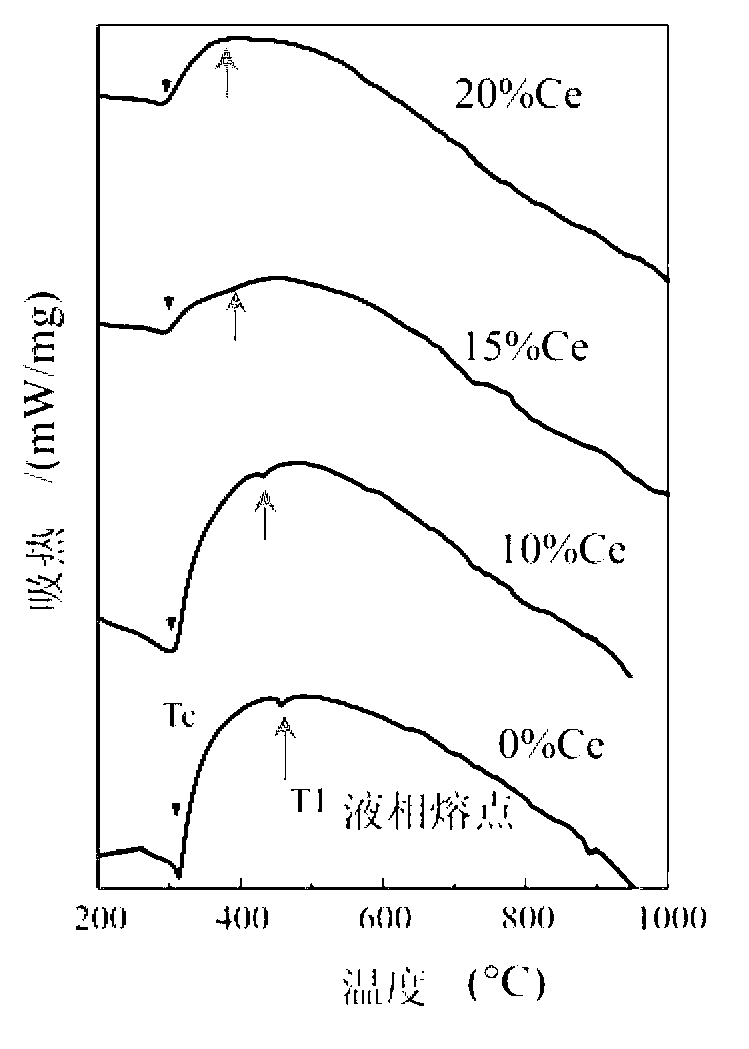

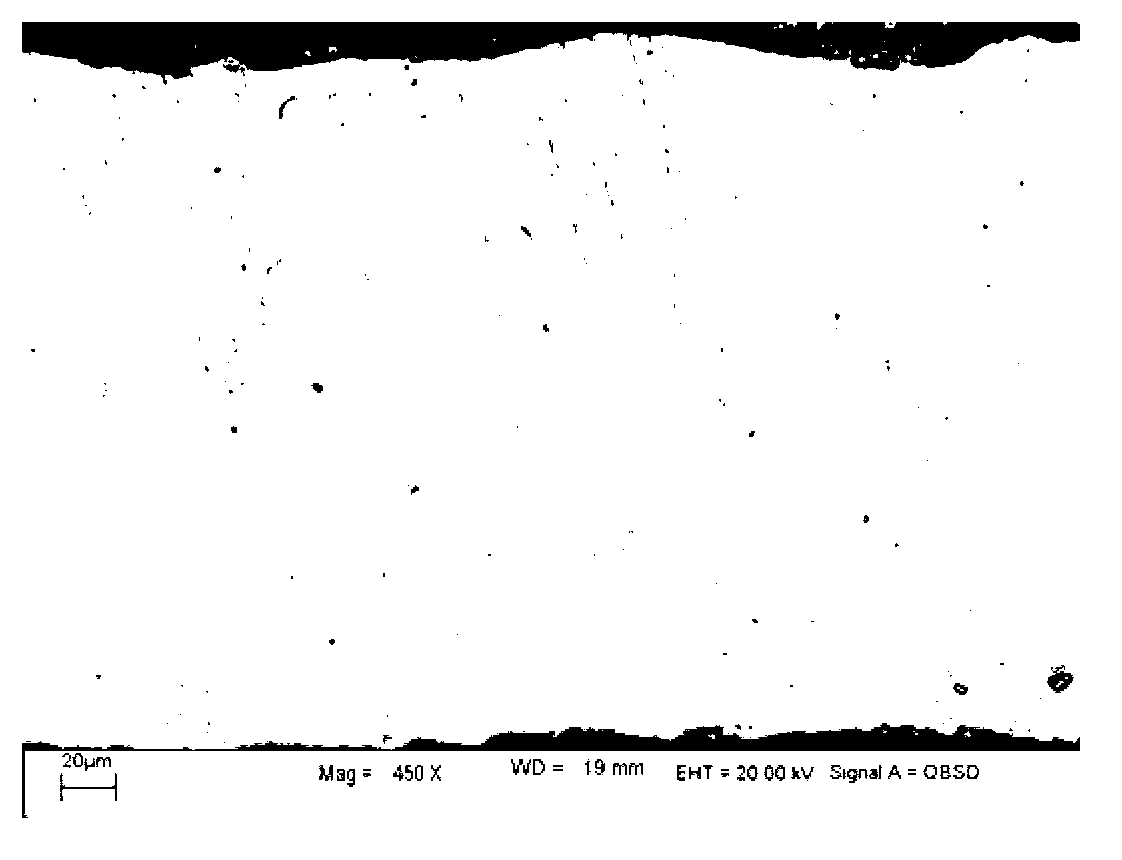

[0045] Step 2: smelting preparation containing Ce 30 -Nd 50 -Fe 20 Quick-setting zone of low-melting liquid alloy. Put the raw materials into the crucible of the quick-setting furnace and conduct vacuum induction smelting under the protection of argon. After the raw materials are fully melted to form an alloy, keep the temperature of 1400~1500℃, and pour the alloy liquid to water cooling with a linear velocity of 2~5 m / s On the copper roller, a quick-setting sheet with a thickness of 0.3mm is prepared with a shape like figure 2 Shown. The rare earth-rich phase (Ce-Nd-Fe) is a white flake structure uniformly distributed between the main phases of neodymium iron boron, wit...

Embodiment 2

[0053] Through the preparation method of the present invention, by adding Ce 30 -Nd 50 -Fe 20 High-performance Ce-Nd-Fe-B magnets are prepared from low-melting liquid phase alloys.

[0054] Step 1: Design the mass percentage of the magnet as Nd 29 Ce 1 Fe 69 B 1 .

[0055] Step 2: Using arc melting, induction melting and other methods to prepare the mass percentage of Ce 30 -Nd 50 -Fe 20 Liquid alloy.

[0056] Step 3: Smelting to prepare Nd 30 Fe 69 B 1 Quick-setting belt. Put the raw materials into the crucible of the quick-setting furnace, and conduct vacuum induction smelting under the protection of argon. After the raw materials are fully melted to form an alloy, keep the temperature of 1400~1500℃, and pour the alloy liquid to water cooling with a linear velocity of 2~5 m / s On a copper roller, a quick-setting sheet with an average thickness of 0.3 mm was prepared.

[0057] Step 4: crushing and milling. Respectively will have Ce 30 -Nd 50 -Fe 20 Liquid alloy and Nd 30 Fe 69 B 1 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com