Method for making high-reflectance microprism reflecting film working mould with ultrasound-pulse electroforming

A technology of pulse electroforming and light reflection, which is applied in the field of microprisms, can solve problems such as difficult control of the light reflection of the working mode of the reflective film, and achieve the effect of convenient forward and reverse pulse parameters and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

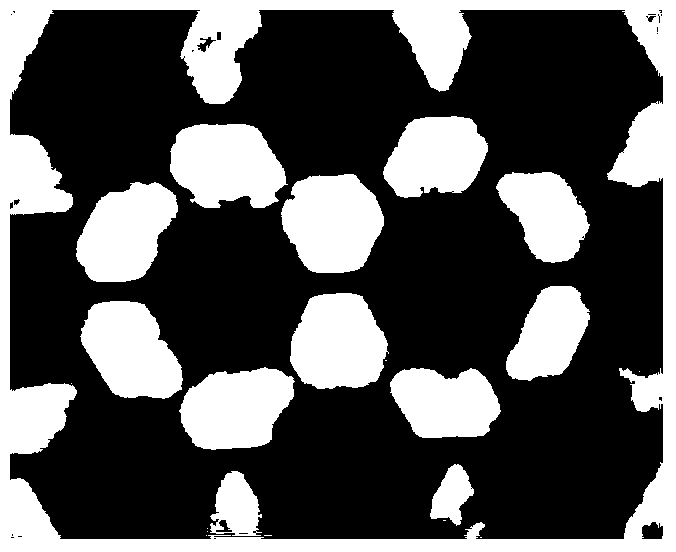

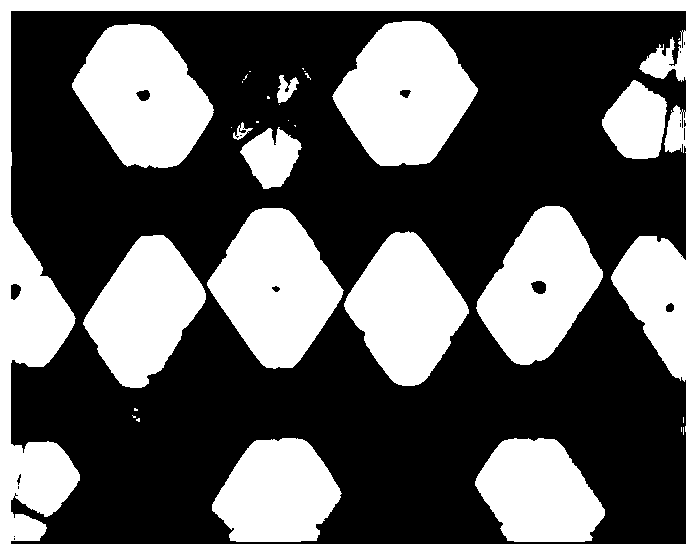

Image

Examples

Embodiment 1

[0022] Electroforming solution preparation: according to the total volume of the electroforming tank, weigh 450g of nickel sulfate, 50g of nickel chloride, 50g of boric acid, 0.07g of sodium lauryl sulfate, 0.5g of saccharin and 0.35g of 1,4-butynediol. g. Add deionized water to the electroforming tank, heat to 50°C, add weighed nickel sulfate and nickel chloride in turn, stir and keep warm for 4 hours. Take another beaker and rinse it with deionized water, dry it, add deionized water, stir and heat to boiling, add weighed boric acid and boil for half an hour, then add sodium lauryl sulfate, wait until sodium lauryl sulfate is fully dissolved Finally, slowly pour it into the electroforming tank, and add saccharin and butynediol to the casting tank, then add deionized water until the electroforming tank is full, stir well, keep warm at 45°C for 12 hours, and measure with pH test paper Its pH value is adjusted to pH=4.2 with 30% sulfuric acid solution. Guaranteed quality-volum...

Embodiment 2

[0029] Nickel sulfate electroforming solution preparation: according to the total volume of the electroforming tank, first weigh 300g of nickel sulfate, 30g of nickel chloride, 30g of boric acid, 0.05g of sodium lauryl sulfate, 0.1g of saccharin and 1,4-butynedi Alcohol 0.2g. Add deionized water to the electroforming tank, heat to 55°C, add weighed nickel sulfate and nickel chloride in turn, stir and keep warm for 3.5h. Take another beaker and rinse it with deionized water, dry it, add deionized water, stir and heat to boiling, add weighed boric acid and boil for 40 minutes, then add sodium lauryl sulfate, wait until sodium lauryl sulfate is fully dissolved Finally, slowly pour it into the electroforming tank, and add saccharin and butynediol into the casting tank, then add deionized water until the electroforming tank is full, stir well, keep warm at 50°C for 10 hours, and measure with pH test paper Its pH value is adjusted to pH=4.2 with 30% sulfuric acid solution. Guarant...

Embodiment 3

[0035]Nickel sulfate electroforming solution preparation: according to the total volume of the electroforming tank, first weigh 600g of nickel sulfate, 70g of nickel chloride, 75g of boric acid, 1g of sodium lauryl sulfate, 1g of saccharin and 0.5 g of 1,4-butynediol g. Add 1 / 2 volume of deionized water to the electroforming tank, heat to 60°C, add weighed nickel sulfate and nickel chloride in turn, stir and keep warm for 3 hours. Take another beaker and rinse it with deionized water, dry it, add deionized water, stir and heat to boiling, add weighed boric acid and boil for 50 minutes, then add sodium lauryl sulfate, wait until sodium lauryl sulfate is fully dissolved Finally, slowly pour it into the electroforming tank, and add saccharin and butynediol into the casting tank, then add deionized water until the electroforming tank is full, stir well, keep it warm at 55°C for 8 hours, and measure it with pH test paper Its pH value is adjusted to pH=4.2 with 30% sulfuric acid so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com