Nickel-cobalt sulfate continuous-crystallizing process

A sulfate and process technology, applied in the direction of nickel sulfate, etc., can solve the problems of high energy consumption, low production efficiency, and high quality requirements of personnel in the evaporation process, and achieve significant energy saving effects, continuous production, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

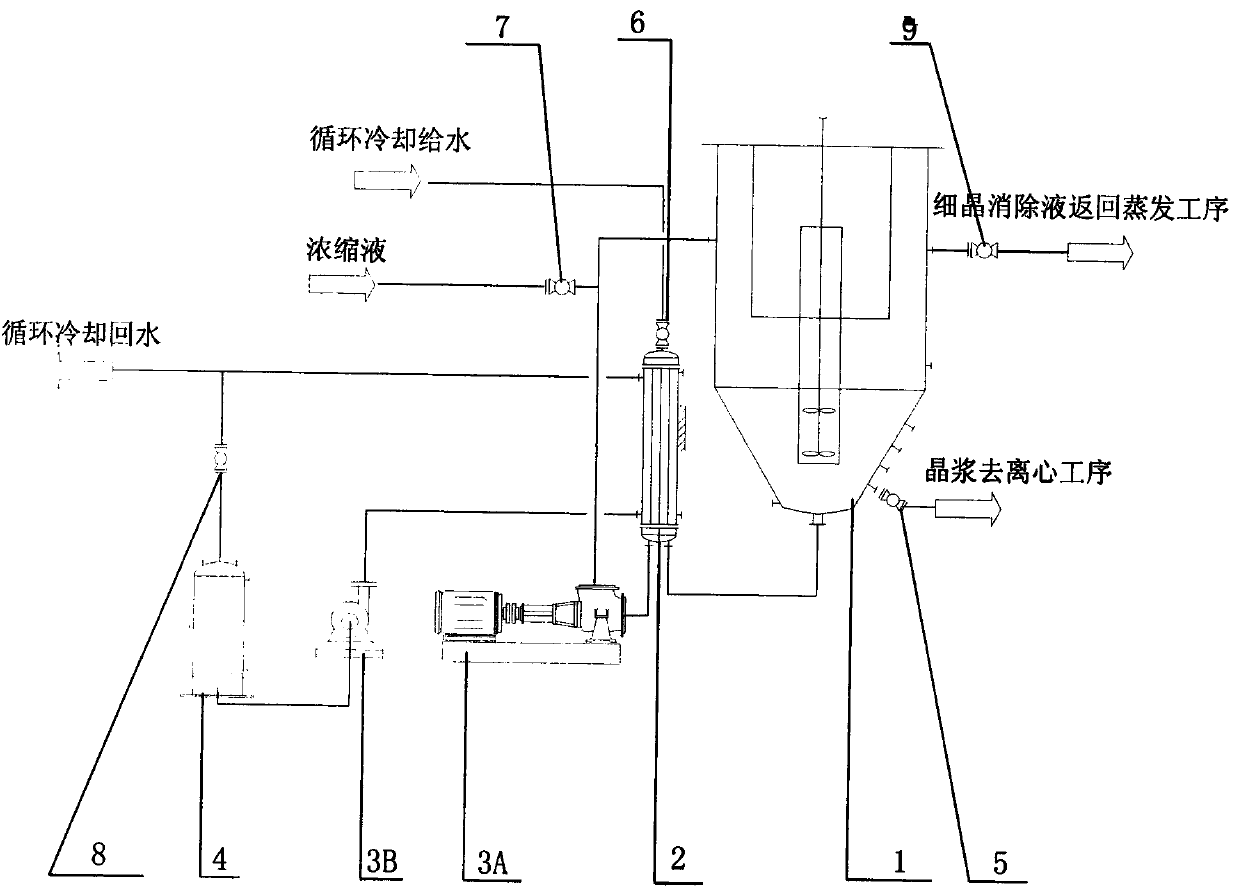

[0015] Control the opening of the valve 7, and the concentration of nickel sulfate at 80-90°C with a solute mass ratio of 37%-39% is 1-4m 3 / h of the flow into the cooling circuit. Control the P01 frequency conversion governor of the cooling circulation pump, and adjust the flow rate of the circulation pump to 900-1100m 3 / h. Control the opening of the valve 6, the flow rate of circulating cooling water is 40~85m 3 / h, so that the cooler discharge temperature is 33 ~ 38 ℃. Control the JB01 frequency conversion governor of the crystallization agitator, and adjust the agitation and discharge volume to 1000-1200m 3 / h, the crystal is in a suspended state, which is conducive to the graded growth of the crystal, and the temperature of the crystal slurry in the crystallizer is 32-35 °C. Valve 9 is closed. Control the opening of the valve 5, and the output of the crystallizer slurry is 1-4m 3 / h, and after centrifugation and drying, 75-80% of nickel sulfate hexahydrate crystal ...

Embodiment 2

[0017] Control the opening of the valve 7, and the concentration of cobalt sulfate at 80-90°C with a solute mass ratio of 30%-33% is 4-8m 3 / h of the flow into the cooling circuit. Control the cooling circulation pump P01 frequency conversion governor, adjust the flow rate of the circulation pump to 1100 ~ 1250m 3 / h. Control the opening of the valve 6, and the circulating cooling water flow rate is 80-97m 3 / h, so that the cooler discharge temperature is 35 ~ 40 ℃. Control the JB01 frequency conversion governor of the crystallization agitator, and adjust the agitation and discharge volume to 1200-1500m 3 / h, the crystal is in a suspended state, which is conducive to the graded growth of the crystal, and the temperature of the crystal slurry in the crystallizer is 32-38 °C. Control the opening of the valve 9, and the return volume of the fine crystal eliminating liquid is 1~2m 3 / h. Control the opening of the valve 5, and the output of the crystallizer slurry is 4-8m 3 ...

Embodiment 3

[0019] Control the opening of the valve 7, and the 80-90°C nickel sulfate concentrate with a solute mass ratio of 38%-39% is 8-10m 3 / h of the flow into the cooling circuit. Control the cooling circulation pump P01 frequency conversion governor, adjust the flow rate of the circulation pump to 1250~1500m 3 / h. Control the opening of the valve 6, the flow rate of circulating cooling water is 85~106m 3 / h, so that the cooler discharge temperature is 39 ~ 45 ℃. Control the JB01 frequency conversion governor of the crystallization agitator, and adjust the agitation and discharge volume to 1500-1800m 3 / h to keep the crystal in a suspended state, and the temperature of the crystal slurry in the crystallizer is 35-43°C. Control the opening of the valve 9, and the return volume of the fine crystal eliminating liquid is 2~3m 3 / h. Control the opening of the valve 5, and the output of the crystallizer slurry is 8-10m 3 / h, and after centrifugation and drying, 85-90% of the nickel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com