Crystal growth method during alpha-type six hydration nickel sulfate interval crystallization process

A technology of nickel sulfate hexahydrate and crystal growth, applied in nickel sulfate and other directions, can solve the problems of extensive control of nickel sulfate variables, dullness, difficult filtration, etc., and achieves easy aggregation or agglomeration, smooth and shiny surface, and strong market. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

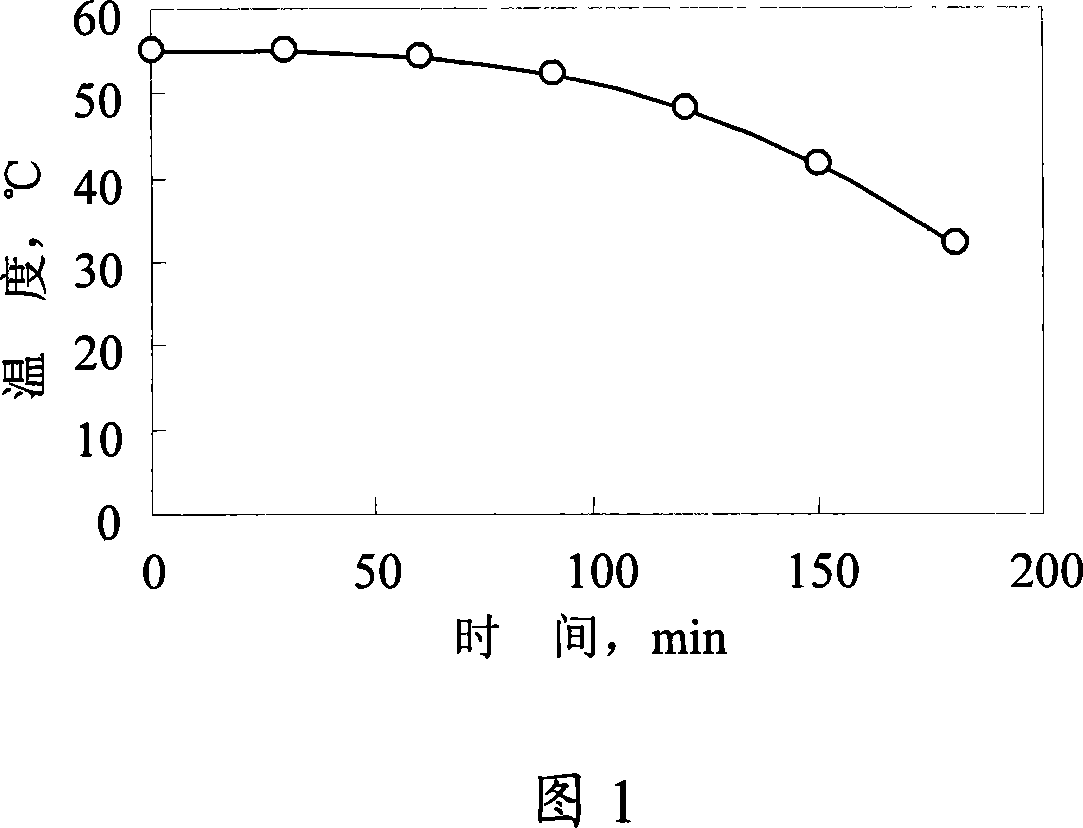

Embodiment 1

[0020] Weigh 100g of industrial-grade nickel sulfate hexahydrate, add 71.6ml of deionized water to mix, use a low-temperature thermostat to raise the temperature of the solution to 65°C, stir to dissolve, control the stirring rate at 150 rpm, and keep warm for 30 minutes; After complete dissolution, adjust the stirring rate to 100 rpm, and linearly cool down to T within 30 minutes with a linear function T=65-0.5t 0 After = 50°C, add 0.5g seed crystals with a particle size of 0.25mm, and use the cubic function T = T 0 - ( T 0 - 31.5 ) × ( t t f ) 3 Curve cooling for cooling and crystallization, when the temperature drops to 31.5°C, the crystal l...

Embodiment 2

[0022] Weigh 88.8g of industrial-grade nickel sulfate hexahydrate, add 63.5ml of deionized water to mix, use a low-temperature thermostat to raise the solution temperature to 65°C, stir to dissolve, control the stirring rate at 140 rpm, and keep warm for 60 minutes; After completely dissolving, adjust the stirring rate to 80 rpm, and linearly lower the temperature to T within 20 minutes with a linear function T=65-0.5t 0 After = 55°C, add 0.3g seed crystals with a particle size of 0.2mm, and use the cubic function T = T 0 - ( T 0 - 31.5 ) × ( t t f ) 3 Curve cooling for cooling and crystallization, when the temperature drops to 32°C, centrifuge...

Embodiment 3

[0024] Weigh 88.8g of industrial-grade nickel sulfate hexahydrate, add 63.5ml of deionized water to mix, use a low-temperature thermostat to raise the solution temperature to 65°C, stir to dissolve, control the stirring rate at 160 rpm, and keep warm for 60 minutes; After complete dissolution, adjust the stirring speed to 90 rpm, and linearly cool down to T within 20 minutes with a linear function T=65-0.5t 0 After =55°C, add 0.2g seed crystals with a particle size of 0.3mm, and use the cubic function T = T 0 - ( T 0 - 31.5 ) × ( t t f ) 3 Curve cooling for cooling and crystallization, when the temperature drops to 31.5°C, the crystal slurry is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com