A kind of supported photocatalyst and preparation method thereof

A photocatalyst and load-type technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of high cost of precious metals, achieve enhanced photocatalytic activity, high hydrogen production activity, and improve photocatalytic production. The effect of hydrogen activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

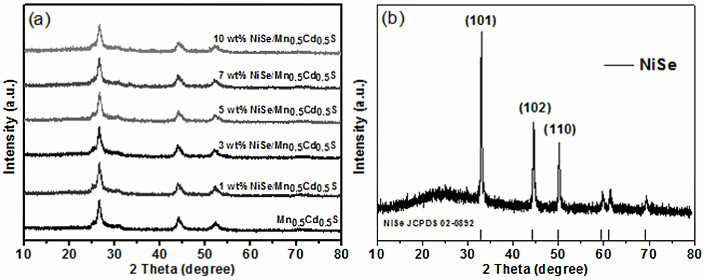

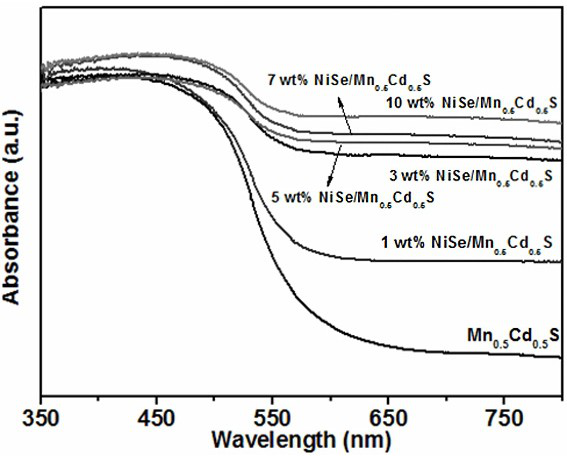

Embodiment 1

[0032] Dissolve 5 mmol of cadmium acetate dihydrate and 5 mmol of manganese acetate tetrahydrate in a beaker containing 40 mL of deionized water and stir to dissolve, then add 10 mmol of thioacetamide, stir for 30 min, and then transfer the solution to polytetrafluoroethylene The ethylene reaction kettle was lined and sealed in a stainless steel reaction kettle, and kept at 160 °C for 24 hours. After cooling down to room temperature, the precipitate was washed with deionized water and absolute ethanol by centrifugation and dried to obtain Mn 0.5 Cd 0.5 S solid solution samples.

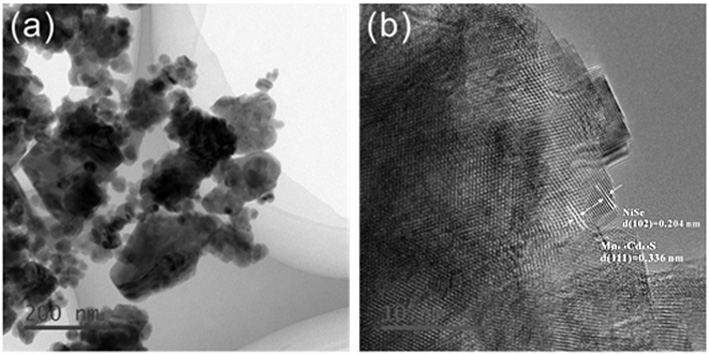

Embodiment 2

[0034] Dissolve 7.3 μmoL nickel sulfate hexahydrate and 7.3 μmoL sodium selenite in a beaker containing 40 mL of ethylene glycol solvent, then add 100 mg of the Mn prepared in Example 1 0.5 Cd 0.5 S solid solution was stirred for 30 min and then transferred into a 50 mL polytetrafluoroethylene liner. After the autoclave was sealed, it was kept at 180 °C for 24 h, and finally cooled down to room temperature naturally. The obtained samples were washed by centrifugation with deionized water and absolute ethanol, and oven-dried at 80 ℃ to obtain 1 wt%-NiSe / Mn 0.5 Cd 0.5 S samples.

Embodiment 3

[0036] Dissolve 22 μmoL nickel sulfate hexahydrate and 22 μmoL sodium selenite in a beaker containing 40mL of ethylene glycol solvent, then add 100 mg of the Mn prepared in Example 1 0.5 Cd 0.5 S solid solution was stirred for 30 min and then transferred into a 50 mL polytetrafluoroethylene liner. After the autoclave was sealed, it was kept at 180 °C for 24 h, and finally cooled down to room temperature naturally. The obtained samples were washed by centrifugation with deionized water and absolute ethanol, and dried in an oven at 80 ℃ to obtain 3 wt%-NiSe / Mn 0.5 Cd 0.5 S samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com