Preparation method of nickel phthalocyanine/copper phthalocyanine/activated carbon Li/SOCl2 battery positive electrode catalytic material

A battery positive electrode and catalytic material technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor catalytic performance and unfavorable full reaction of the battery positive electrode, and achieve the goal of improving electron conductivity, catalytic activity, and high conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

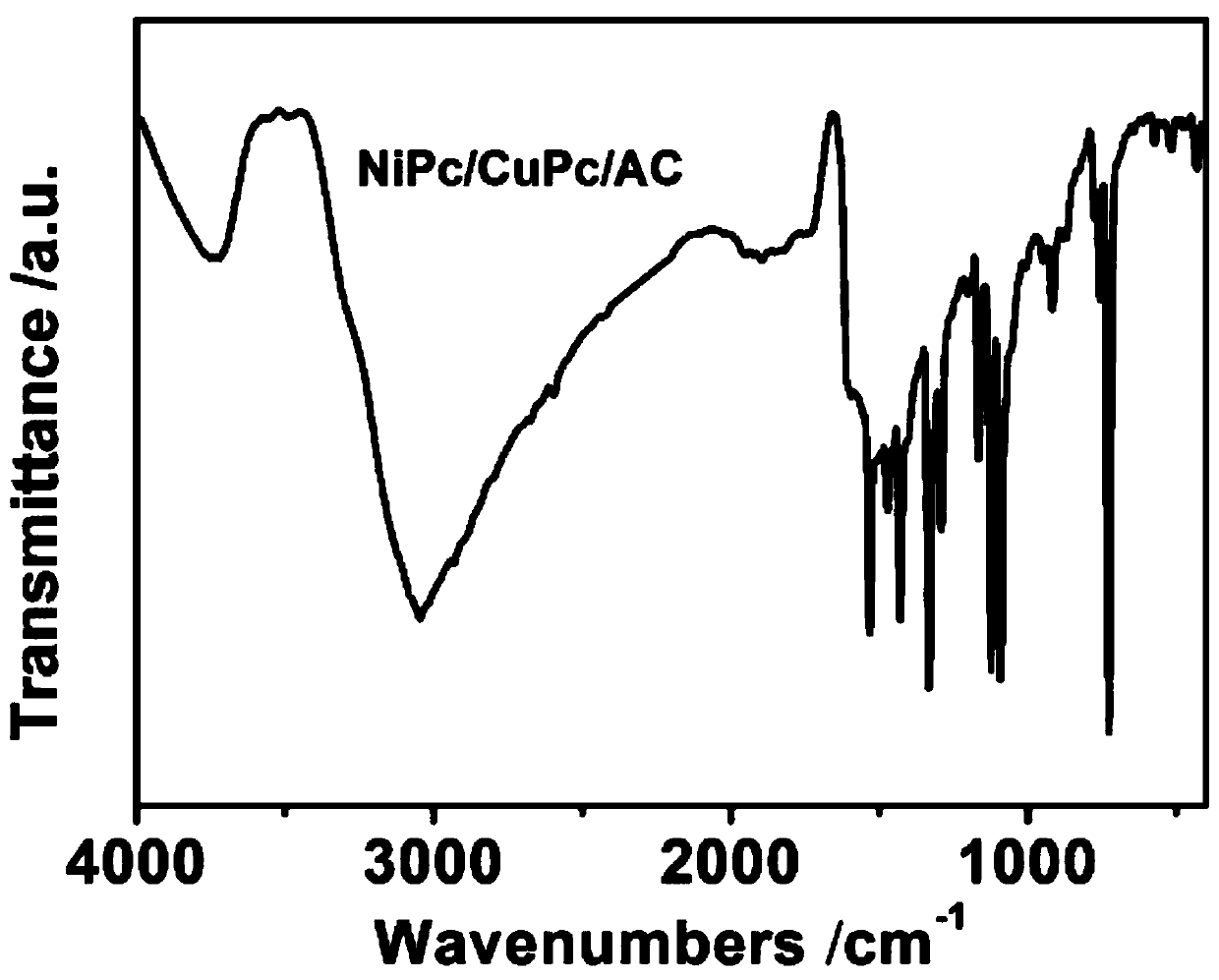

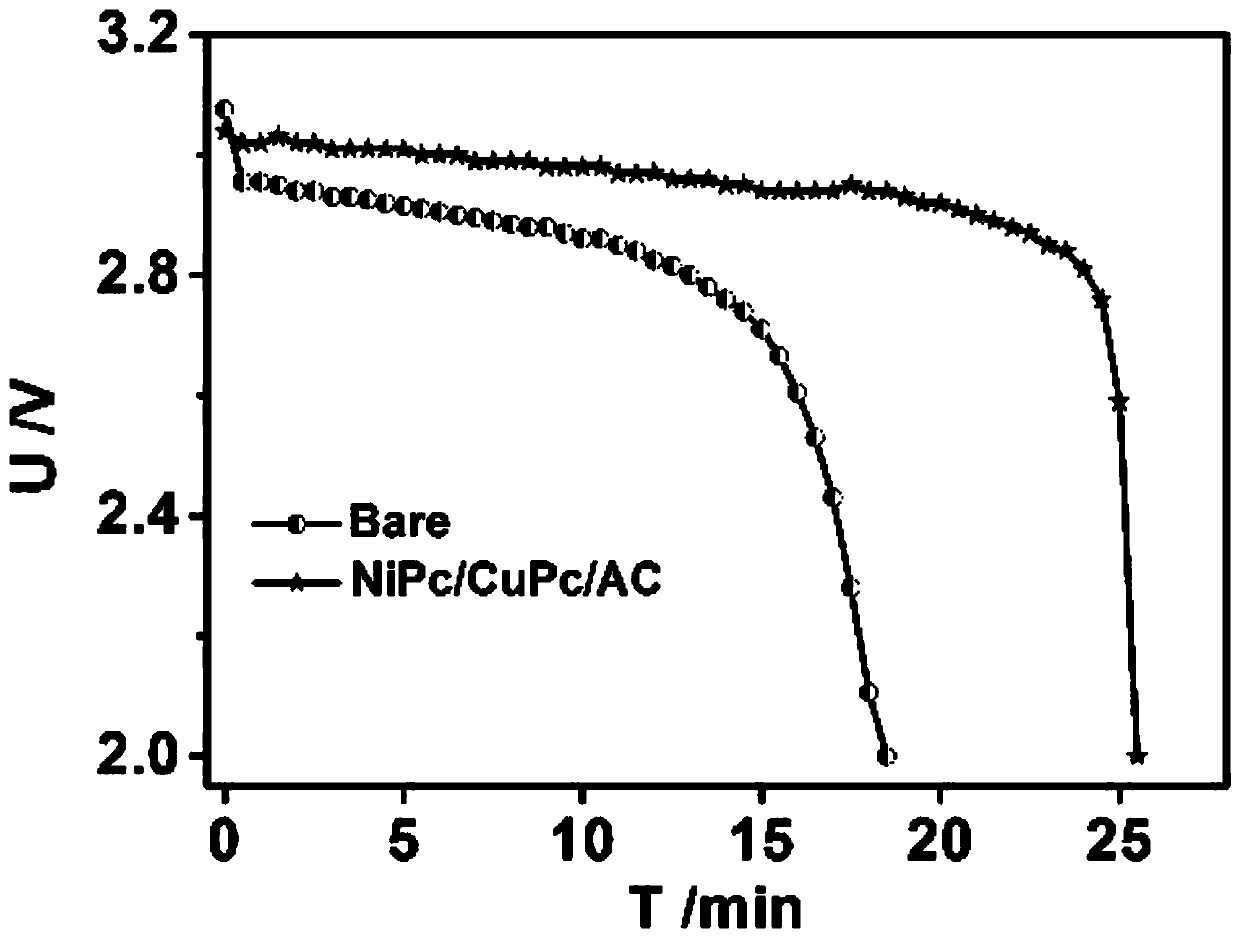

[0021] A kind of nickel phthalocyanine / copper phthalocyanine / activated carbon Li / SOCl 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0022] Step 1: Take 0.80g of phthalic anhydride and 0.08g of phthalic anhydride with a specific surface area of 1400m 2 / g of pitch coke activated carbon, urea of 1.00g, ammonium molybdate tetrahydrate of 0.10g, nickel chloride hexahydrate of 0.55g and cupric chloride dihydrate of 0.04g are mixed and placed in a mortar and thoroughly ground to obtain mixture;

[0023] Step 2: Put the mixture in a crucible and put it into a muffle furnace, then raise the temperature from room temperature to 130°C at a rate of 7°C / min and keep it for 30 minutes, and then increase the rate of temperature to 250°C at a rate of 7°C / min And keep it warm for 2.5h to carry out solid-phase sintering, and cool to room temperature to obtain a crude product;

[0024] Step 3: Grind the crude product, was...

Embodiment 2

[0029] A kind of nickel phthalocyanine / copper phthalocyanine / activated carbon Li / SOCl 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0030] Step 1: Take 0.60g of phthalic anhydride and 0.06g of phthalic anhydride with a specific surface area of 1400m 2 The pitch coke activated carbon of / g, the urea of 0.80g, the ammonium molybdate tetrahydrate of 0.08g, the nickel chloride hexahydrate of 0.45g and the cupric chloride dihydrate of 0.03g are mixed and placed in a mortar and thoroughly ground to obtain mixture;

[0031] Step 2: Put the mixture in a crucible and place it in a muffle furnace, then start from room temperature at 6 °C min -1 The heating rate was raised to 120°C and kept for 20 minutes, and then raised to 230°C at a heating rate of 6°C / min and kept for 2 hours for solid-phase sintering, and cooled to room temperature to obtain a crude product;

[0032] Step 3: Grind the crude product, wash and p...

Embodiment 3

[0034] A kind of nickel phthalocyanine / copper phthalocyanine / activated carbon Li / SOCl 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0035] Step 1: Take 1.00g of phthalic anhydride and 0.10g of phthalic anhydride with a specific surface area of 1400m 2 The pitch coke activated carbon of / g, the urea of 1.20g, the ammonium molybdate tetrahydrate of 0.12g, the nickel chloride hexahydrate of 0.65g and the cupric chloride dihydrate of 0.05g are mixed and then placed in a mortar and thoroughly ground evenly to obtain mixture;

[0036] Step 2: Put the mixture in a crucible and put it into a muffle furnace, then raise the temperature from room temperature to 140°C at a rate of 8°C / min and keep it for 40 minutes, and then increase the rate of temperature to 270°C at a rate of 8°C / min And keep warm for 3h to carry out solid phase sintering, cool to room temperature, get crude product;

[0037]Step 3: Grind the cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com