Preparation method of cobaltous sulfide nickel/graphene composite gel and application

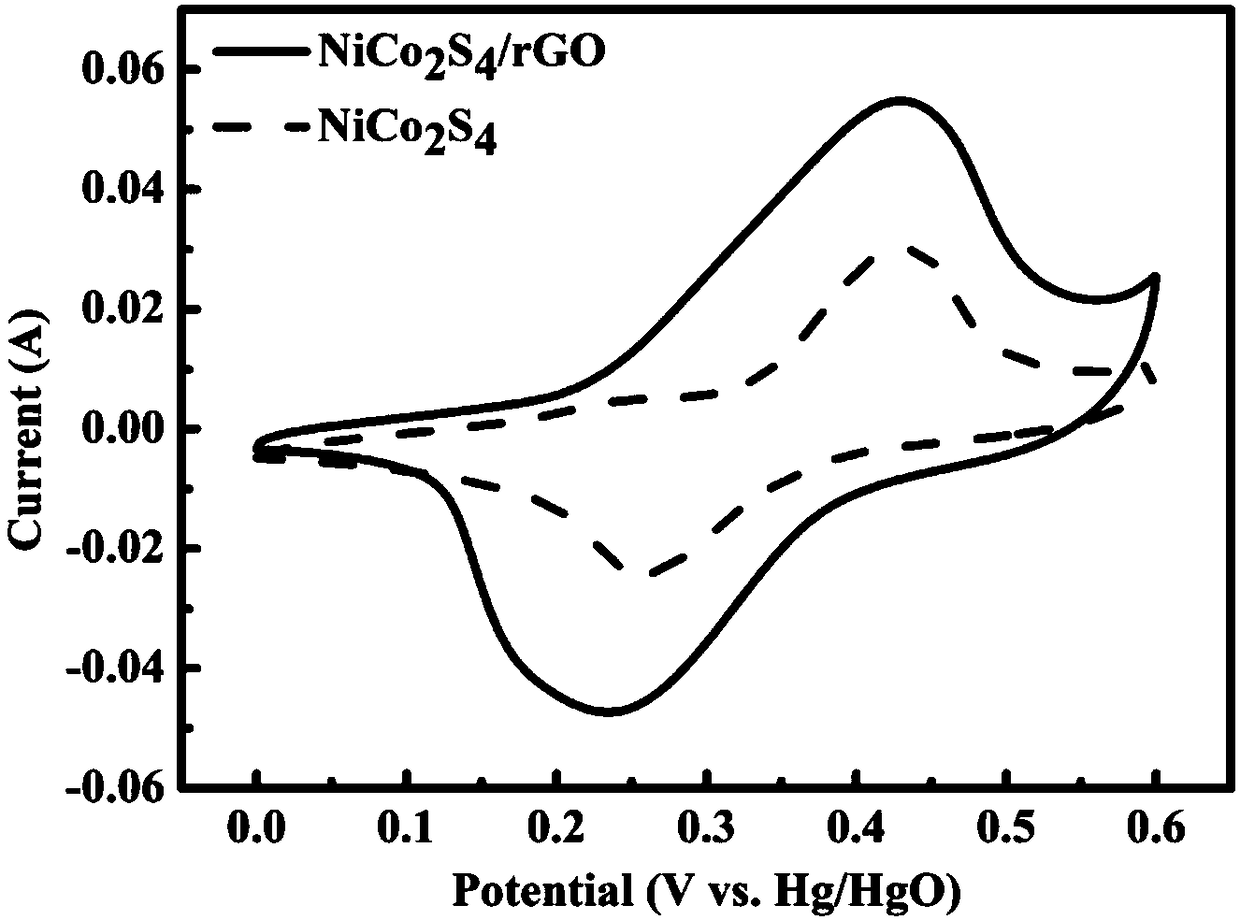

A graphene composite, cobalt-nickel sulfide technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrolytes, etc., can solve the problems that affect the energy storage cycle stability and specific capacity, and the active sites cannot be fully exposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

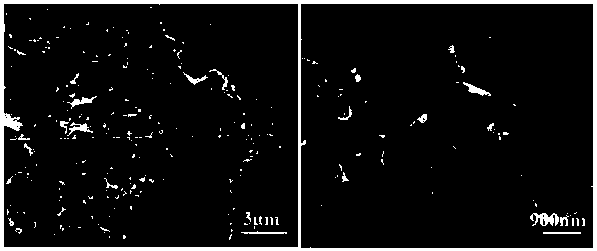

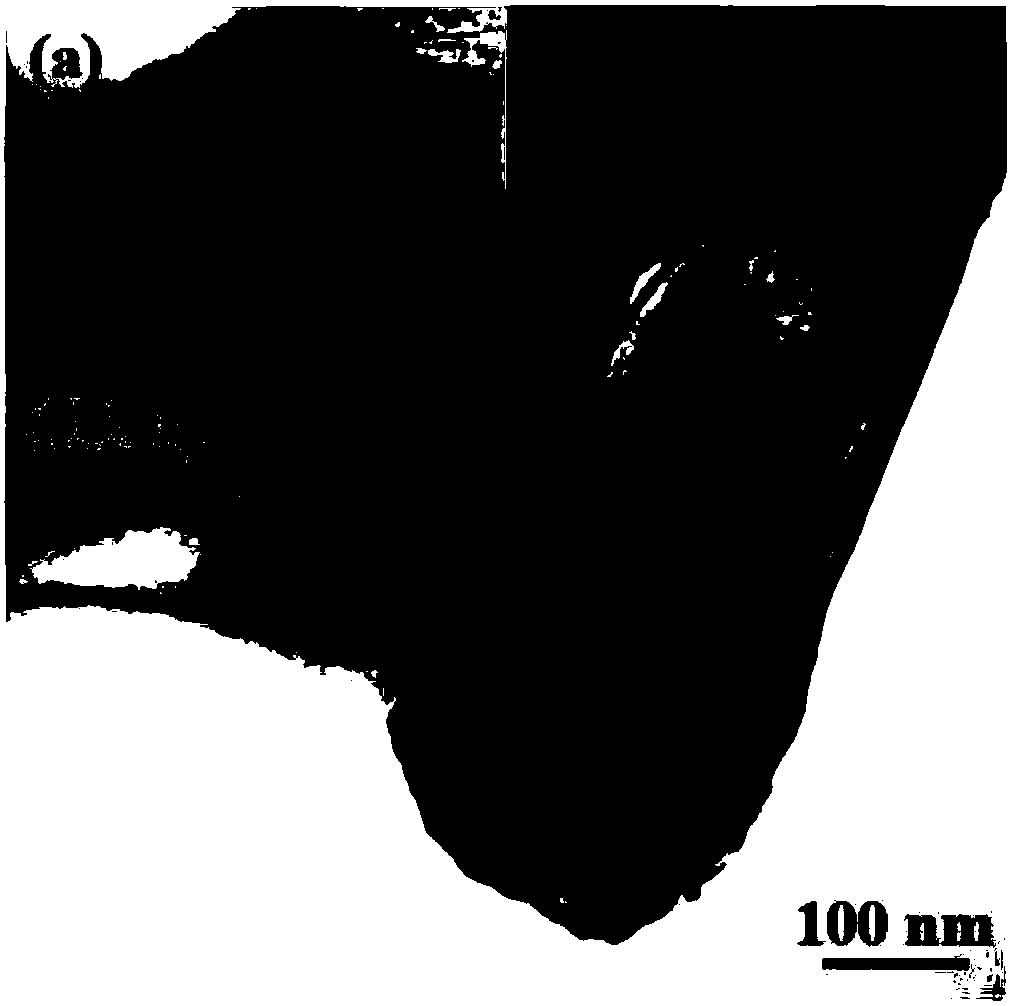

[0041] 1. Preparation of cobalt-nickel sulfide / graphene composite gel

[0042] (1) First, graphene oxide is added to 95wt% ethanol, and ultrasonically dispersed to obtain a stably dispersed 1 mg / mL graphene oxide alcohol solution;

[0043] (2) Then according to the feed ratio of 1.68:1 (with the synthesized NiCo 2 S 4 In terms of the ratio of the mass of nickel to the mass of graphene), 0.2908g (1mmol) Ni (NO 3 ) 2 ·6H 2 O, 0.5821g (2mmol) Co (NO 3 ) 2 ·6H 2 O and 0.3005g (4mmol) thioacetamide are dissolved in the graphene oxide alcohol solution of 35mL, 1mg / mL, after stirring evenly, ultrasonic 3h, obtain mixed solution;

[0044] (3) Then transfer the obtained mixed solution to a 50mL autoclave, lock it, place the autoclave in a constant temperature blast drying oven, and heat the reaction at 150°C for 24h;

[0045] (4) After the heating reaction is completed, the autoclave is cooled to room temperature, and the black columnar hydrogel reaction product obtained by the...

Embodiment 2

[0053] 1. Preparation of cobalt-nickel sulfide / graphene composite gel

[0054] (1) First, graphene oxide is added to 95wt% ethanol, and ultrasonically dispersed to obtain a stably dispersed 2 mg / mL graphene oxide alcohol solution;

[0055] (2) Then according to the feed ratio of 0.84:1 (with the synthesized NiCo 2 S 4 In terms of the ratio of the mass of nickel to the mass of graphene), 0.2908g (1mmol) Ni (NO 3 ) 2 ·6H 2 O, 0.5821g (2mmol) Co (NO 3 )2 ·6H 2 O and 0.3005g (4mmol) thioacetamide are dissolved in the graphene oxide alcohol solution of 35mL, 2mg / mL, after stirring evenly, ultrasonic 3h, obtain mixed solution;

[0056] (3) Then transfer the obtained mixed solution to a 50mL autoclave, lock it, place the autoclave in a constant temperature blast drying oven, and heat the reaction at 150°C for 24h;

[0057] (4) After the heating reaction is completed, the autoclave is cooled to room temperature, and the black columnar hydrogel reaction product obtained by the r...

Embodiment 3

[0065] 1. Preparation of cobalt-nickel sulfide / graphene composite gel

[0066] (1) First, graphene oxide is added to 95wt% ethanol, and ultrasonically dispersed to obtain a stably dispersed 3 mg / mL graphene oxide alcohol solution;

[0067] (2) Then according to the feed ratio of 0.56:1 (with the synthesized NiCo 2 S 4 In terms of the ratio of the mass of nickel to the mass of graphene), 0.2908g (1mmol) Ni (NO 3 ) 2 ·6H 2 O, 0.5821g (2mmol) Co (NO 3 ) 2 ·6H 2 O and 0.3005g (4mmol) thioacetamide are dissolved in the graphene oxide alcohol solution of 35mL, 3mg / mL, after stirring evenly, ultrasonic 3h, obtain mixed solution;

[0068] (3) Then transfer the obtained mixed solution to a 50mL autoclave, lock it, place the autoclave in a constant temperature blast drying oven, and heat the reaction at 150°C for 24h;

[0069] (4) After the heating reaction is completed, the autoclave is cooled to room temperature, and the black columnar hydrogel reaction product obtained by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com