Two-dimensional transition metal carbide/titanium dioxide/graphene composite material, preparation and application thereof

A technology of titanium dioxide and composite materials, used in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of poor cycle stability and low energy density of lithium-ion capacitors, and achieve high power density, enhanced conductivity, high The effect of volumetric capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

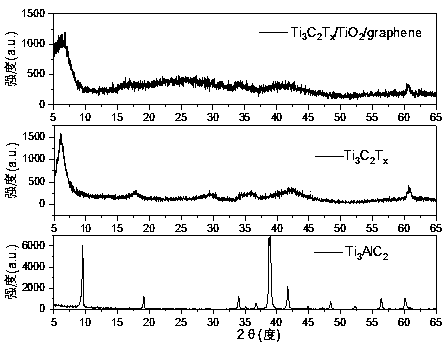

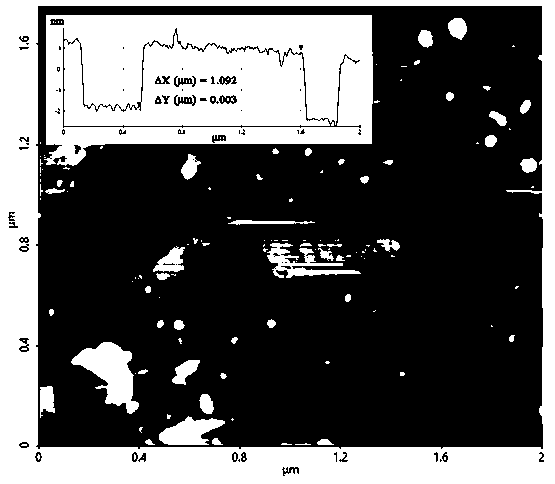

[0028] Example 1: Weigh 1g LiF and put it in a 100mL hydrothermal reaction kettle, add 20 mL 9M HCl solution, stir at 550rpm for 10min; then, slowly add 1g Ti in an ice bath 3 AlC 2 , Subsequently, the reactor was transferred to a 35°C water bath, and stirred at a constant temperature for 48h. Centrifugal washing with deionized water to pH greater than 5, freeze-drying for 24 hours to obtain multilayered Ti 3 C 2 . The above multilayer Ti 3 C 2 Add 200mL deionized water, sonicate for 2h, and centrifuge at 3500rpm for 40min. The obtained supernatant was transferred to a bottle and ventilated with Ar gas for 10 min, then wrapped in aluminum foil to avoid light, and stored in refrigerator. The graphite oxide is ultrasonically dispersed in water to obtain a graphene oxide dispersion. Take the Ti obtained above 3 C 2 T x The dispersion liquid and the GO dispersion liquid are mixed according to the mass ratio of 95:5, ultrasonically mixed, and 5% GO / Ti is obtained by sucti...

Embodiment 2

[0031] Example 2: Weigh 1g LiF and place it in a 100mL hydrothermal reaction kettle, add 20 mL 9M HCl solution, stir at 550rpm for 10min; then, slowly add 1g Ti in an ice bath 3 AlC 2 , Subsequently, the reactor was transferred to a 35°C water bath, and stirred at a constant temperature for 48h. Centrifugal washing with deionized water to pH greater than 5, freeze-drying for 24 hours to obtain multilayered Ti 3 C 2 . The above multi-layer multi-layer Ti 3 C 2 (Ml-TC) was added with 200 mL deionized water, ultrasonicated for 2 h, and centrifuged at 3500 rpm for 40 min. The obtained supernatant was transferred to a bottle and ventilated with Ar gas for 10 min, then wrapped in aluminum foil to avoid light, and stored in refrigerator. The graphite oxide is ultrasonically dispersed in water to obtain a graphene oxide dispersion. Take the Ti obtained above 3 C 2 T x The dispersion liquid and the graphene oxide dispersion liquid (GO) were mixed ultrasonically according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com