Process for dry type ore grinding employing vertical roller mill

A vertical roller mill and vertical roller mill technology, which is applied in the raw ore boiling roasting process, can solve the problems of complex process, large investment in equipment, site, environmental protection, etc., and uneven combustion of pulverized coal, so as to increase the specific surface area , save space and investment, improve the effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

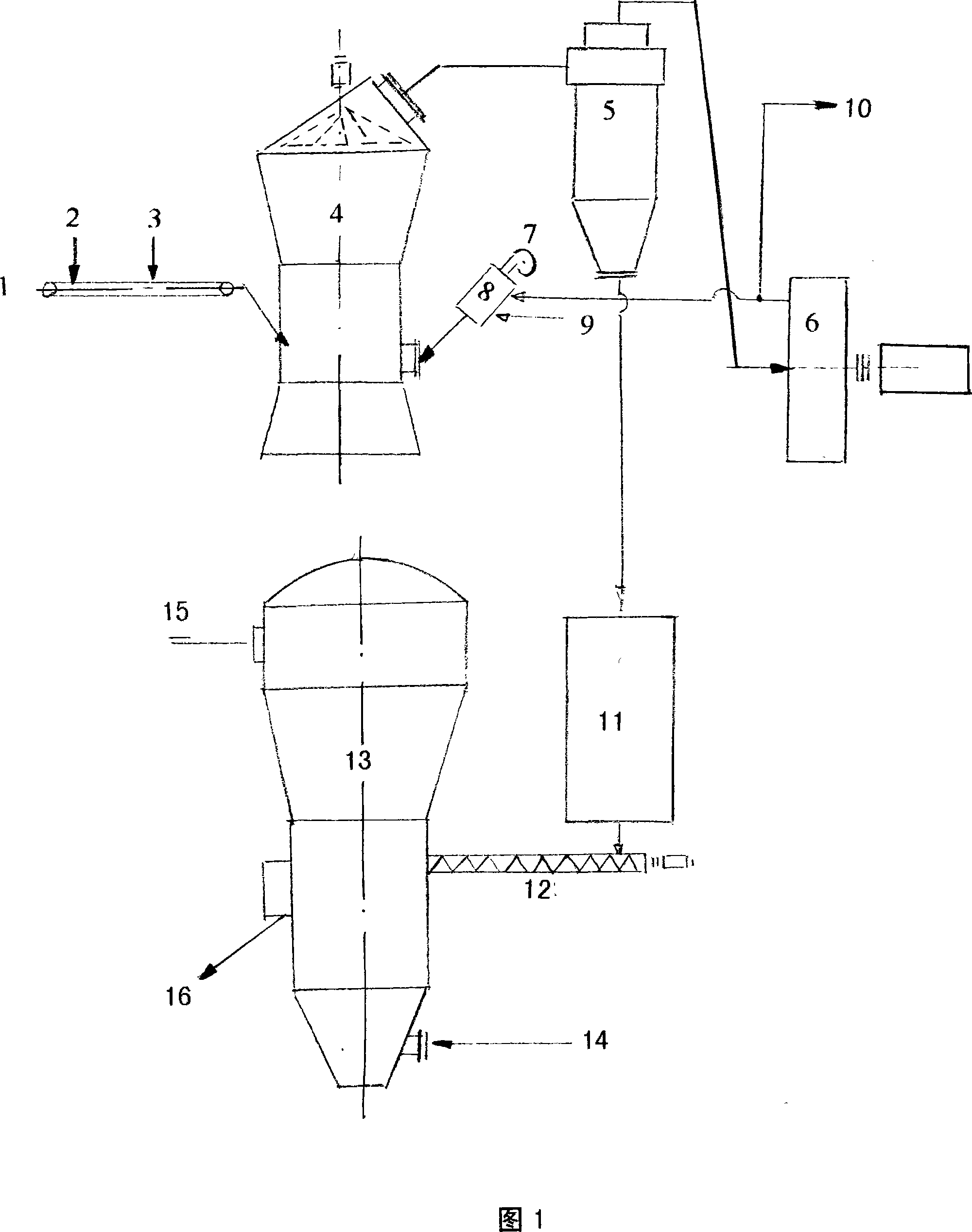

[0021] As shown in accompanying drawing 1, processing step of the present invention is as follows:

[0022] Step 1: Crushing

[0023] The ore extracted from the underground is crushed to a particle size of -70mm after a stage of coarse crushing and a stage of intermediate crushing. The lump coal 3 and the crushed ore 2 are fed into the high-pressure vertical roller mill through the belt conveyor 1 under automatic measurement and control conditions. Carry out dry grinding in machine 4;

[0024] Step 2: Dry Grinding

[0025] The crushed ore 2 and coal block 3 entering the high-pressure vertical roller mill 4 are firstly supplied with hot air 9 by a circulating induced draft fan 6, and the hot air 9 enters the air mixing chamber 8 and is formed by a fuel burner to form a hot air temperature of 250°C for direct drying Ore 2 and coal block 3, the circulating air volume of the circulating induced draft fan 6 is 135000m 3 / h; vertical roller mill 4 air inlet negative pressure -400...

Embodiment 2

[0029] As shown in accompanying drawing 1, processing step of the present invention is as follows:

[0030] Step 1: Crushing

[0031] The ore extracted from the underground is crushed to a particle size of -70mm after a stage of coarse crushing and a stage of intermediate crushing. The lump coal 3 and the crushed ore 2 are fed into the high-pressure vertical roller mill through the belt conveyor 1 under automatic measurement and control conditions. Carry out dry grinding in machine 4;

[0032] Step 2: Dry Grinding

[0033] The crushed ore 2 and coal block 3 entering the high-pressure vertical roller mill 4 are firstly supplied with hot air 9 by a circulating induced draft fan 6, and the hot air 9 enters the air mixing chamber 8 and is formed by a fuel burner to form a hot air temperature of 250°C for direct drying Ore 2 and coal block 3, the circulating air volume of the circulating induced draft fan 6 is 153000m 3 / h; vertical roller mill 4 air inlet negative pressure -450...

Embodiment 3

[0037] As shown in accompanying drawing 1, processing step of the present invention is as follows:

[0038] Step 1: Crushing

[0039] The ore extracted from the underground is crushed to a particle size of -70mm after a stage of coarse crushing and a stage of intermediate crushing. The lump coal 3 and the crushed ore 2 are fed into the high-pressure vertical roller mill through the belt conveyor 1 under the condition of automatic measurement and control. Carry out dry grinding in machine 4;

[0040] Step 2: Dry Grinding

[0041]The crushed ore 2 and coal block 3 entering the high-pressure vertical roller mill 4 are firstly supplied with hot air 9 by a circulating induced draft fan 6, and the hot air 9 enters the air mixing chamber 8 and is formed by a fuel burner to form a hot air temperature of 250°C for direct drying Ore 2 and coal block 3, the circulating air volume of the circulating induced draft fan 6 is 162000m 3 / h; vertical roller mill 4 air inlet negative pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com