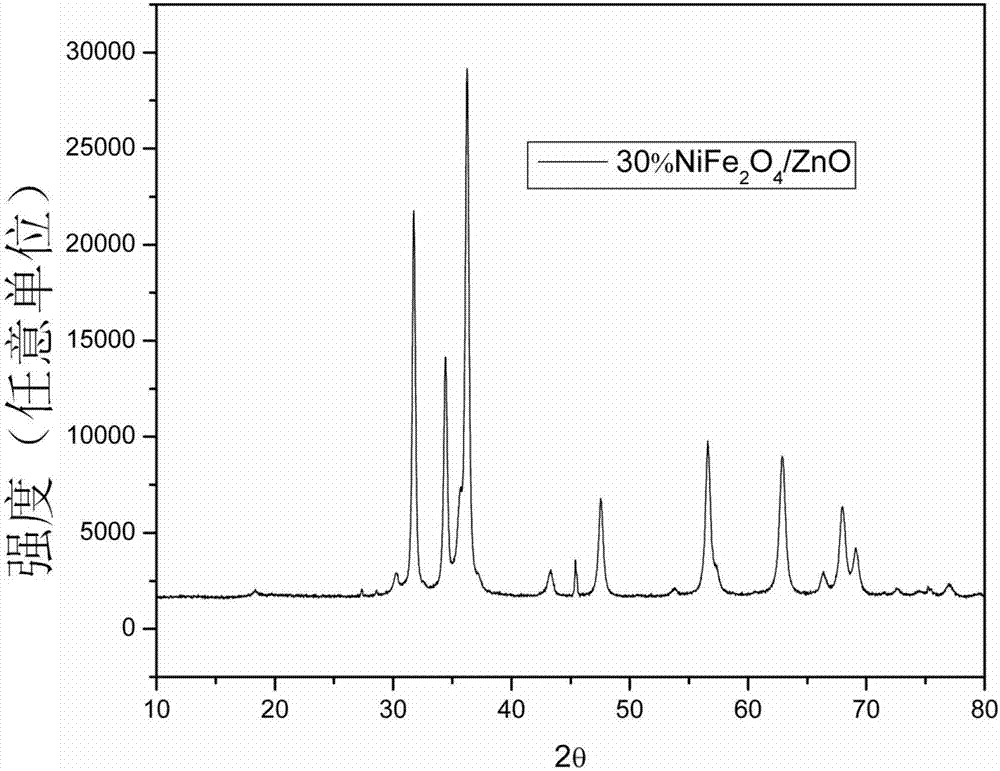

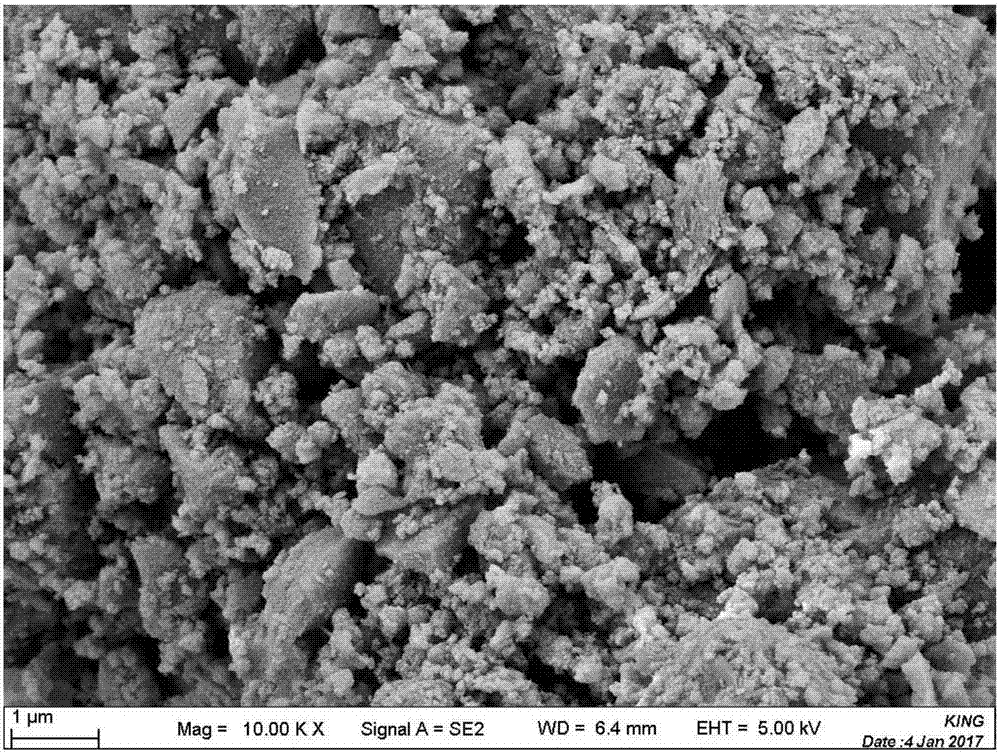

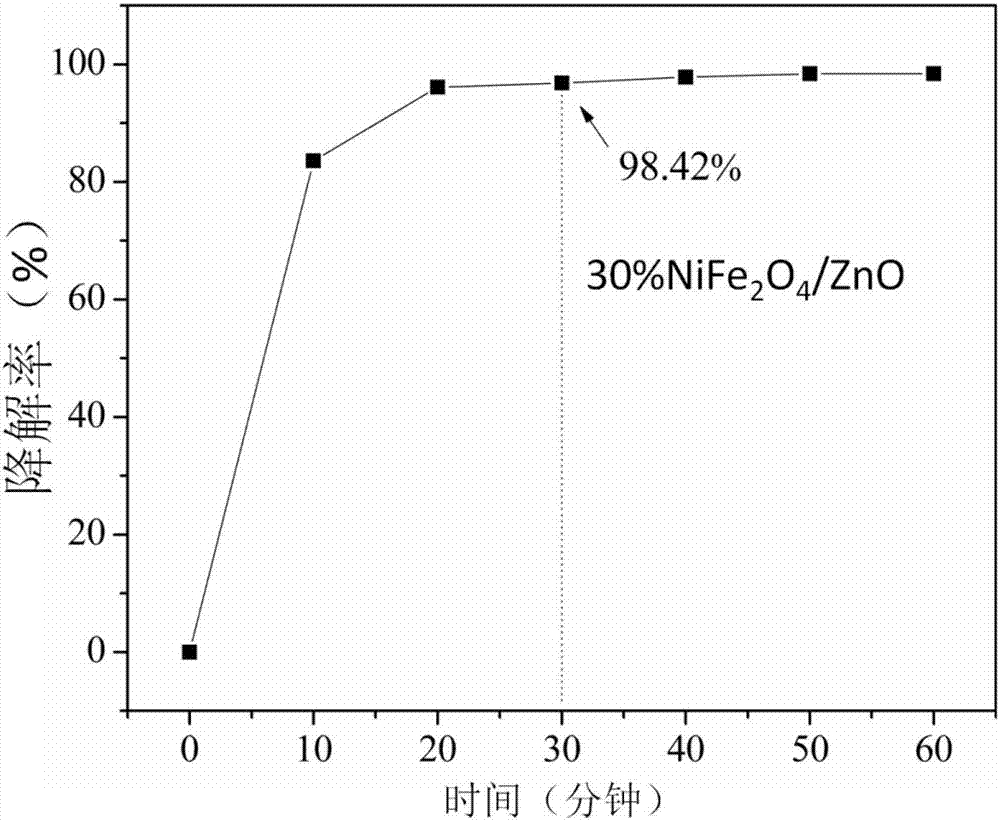

Preparation method and application of magnetic heterogeneous photo-Fenton NiFe2O4/ZnO composite nano material

A composite nanomaterial, magnetic technology, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc. , to achieve the effect of good reusability, short time-consuming and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A Magnetic Out-of-Phase Photo-Fenton NiFe 2 o 4 The preparation method of / ZnO composite nano material, it comprises the following steps:

[0026] Ⅰ)NiFe 2 o 4 Preparation of:

[0027] (1) Weigh nickel chloride hexahydrate and ferric chloride hexahydrate respectively according to the molar ratio of iron and nickel being 2:1, dissolve them in deionized water, and ultrasonically treat them for 60 minutes, and stir them magnetically for 30 minutes;

[0028] (2) Heating the mixed solution to 90° C. for 3 hours, adding dropwise sodium hydroxide solution to the mixed solution to adjust the pH value to 13;

[0029] (3) Transfer the heated solution to a polytetrafluoroethylene-lined stainless steel autoclave, put the autoclave into a muffle furnace, heat it up to 600°C in a sealed manner with a temperature increase of 3°C per minute, and keep it warm for 3h;

[0030] (4) The powder solid obtained after heating is separated in a magnetic field, and then the magnetic powder i...

Embodiment 2

[0039] Ⅰ)NiFe 2 o 4 Preparation of:

[0040] (1) Weigh nickel chloride hexahydrate and ferric chloride hexahydrate respectively according to the molar ratio of iron and nickel being 2:1.5, dissolve them in deionized water, and ultrasonically treat them for 60 minutes, and magnetically stir for 30 minutes;

[0041] (2) Heating the mixed solution to 80° C. for 3.5 hours, adding sodium hydroxide solution dropwise to the mixed solution to adjust the pH value to 14;

[0042] (3) Transfer the heated solution to a polytetrafluoroethylene-lined stainless steel autoclave, put the autoclave into a muffle furnace, heat up to 800°C in a sealed manner with a temperature rise of 3°C per minute, and keep it warm for 2.5h;

[0043] (4) The powder solid obtained after heating is separated in a magnetic field, and then the magnetic powder is washed and dried to obtain a magnetic heterogeneous photo-Fenton catalyst NiFe 2 o 4 ;

[0044] Ⅱ)NiFe 2 o 4 / ZnO magnetic composite preparation:

...

Embodiment 3

[0050] Ⅰ)NiFe 2 o 4 Preparation of:

[0051] (1) Weigh nickel chloride hexahydrate and ferric chloride hexahydrate respectively according to the molar ratio of iron and nickel being 2:1, dissolve them in deionized water, and ultrasonically treat them for 60 minutes, and stir them magnetically for 30 minutes;

[0052] (2) Heating the mixed solution to 100° C. for 2.5 hours, adding sodium hydroxide solution dropwise to the mixed solution to adjust the pH value to 10;

[0053] (3) Transfer the heated solution to a polytetrafluoroethylene-lined stainless steel autoclave, put the autoclave into a muffle furnace, heat up to 700°C in a closed manner with a temperature increase of 3°C per minute, and keep it warm for 3h;

[0054] (4) The powder solid obtained after heating is separated in a magnetic field, and then the magnetic powder is washed and dried to obtain a magnetic heterogeneous photo-Fenton catalyst NiFe 2 o 4 ;

[0055] Ⅱ)NiFe 2 o 4 / ZnO magnetic composite preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com