Preparation method and application of NiFe2O4/Cu2O magnetic composite nanometer catalyst

A magnetic composite nano-catalyst technology, applied in heterogeneous catalyst chemical elements, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex process, small specific surface area, large catalyst particles, etc., and achieve simple process. , The effect of high processing efficiency and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

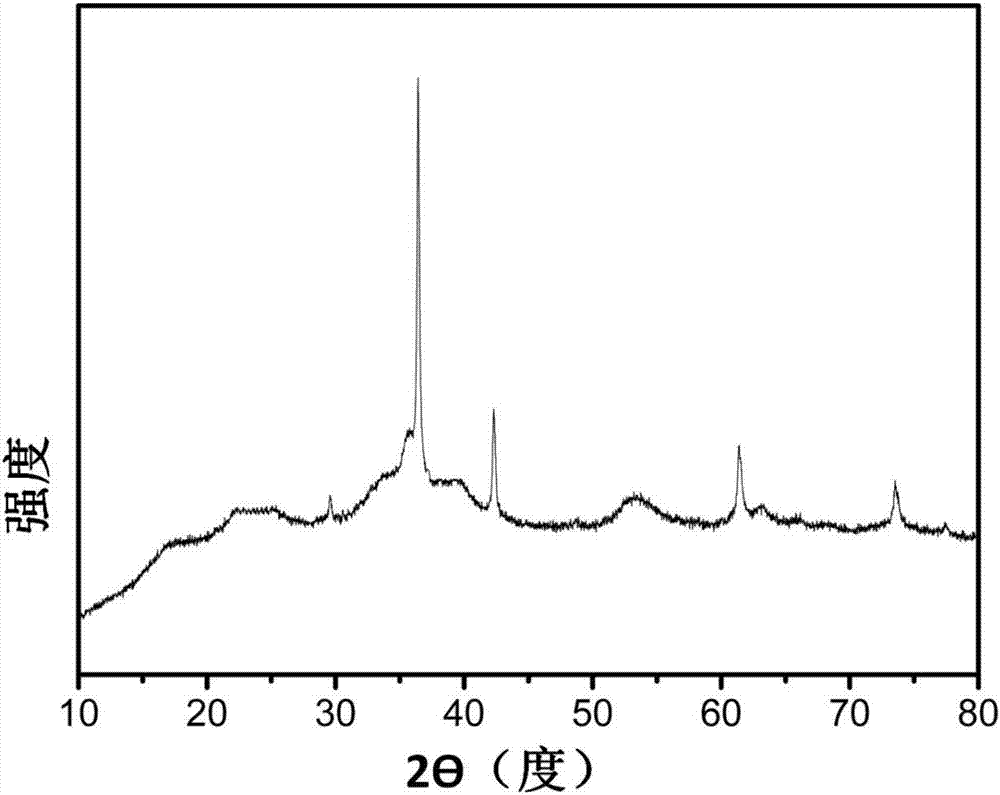

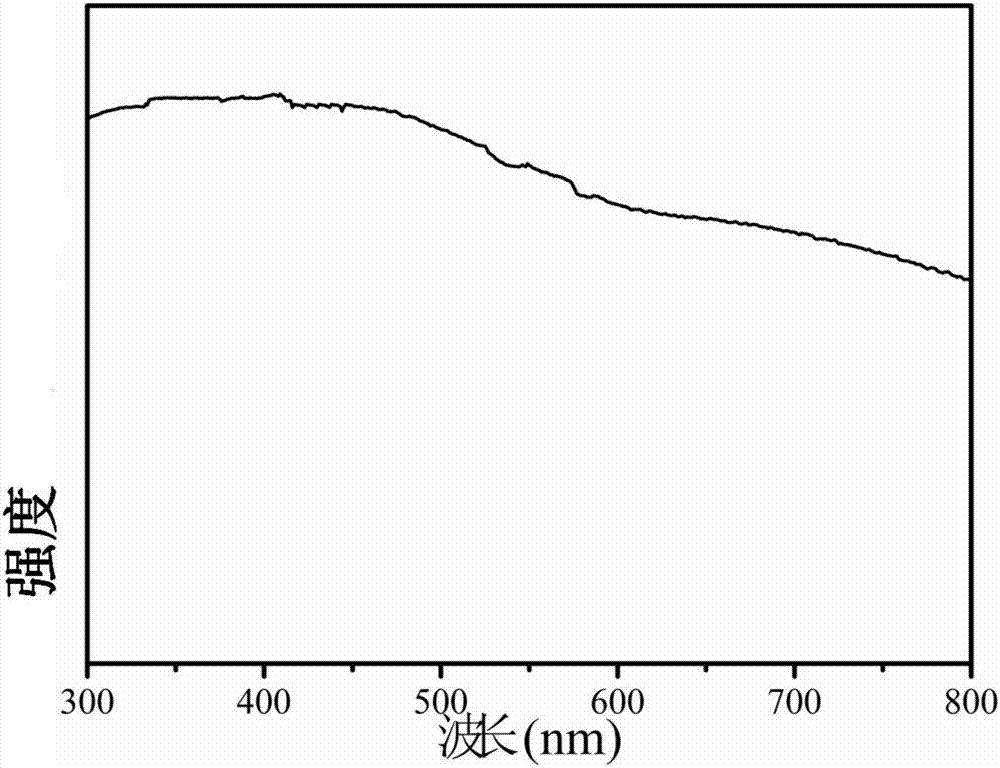

[0027] A NiFe 2 o 4 / Cu 2 The preparation method of O magnetic composite nano-catalyst, it may further comprise the steps:

[0028] Ⅰ)NiFe 2 o 4 Preparation of:

[0029] (1) taking by weighing nickel chloride hexahydrate and ferric chloride hexahydrate respectively as 2:1 by the mol ratio of iron and nickel and being dissolved in deionized water;

[0030] (2) Add sodium hydroxide solution dropwise to the mixed solution to adjust the pH value to 13, and heat the mixed solution to 90° C. for 3 hours;

[0031] (3) Transfer the heated solution to the reactor, and heat the reactor to 700° C. and keep it warm for 3 hours;

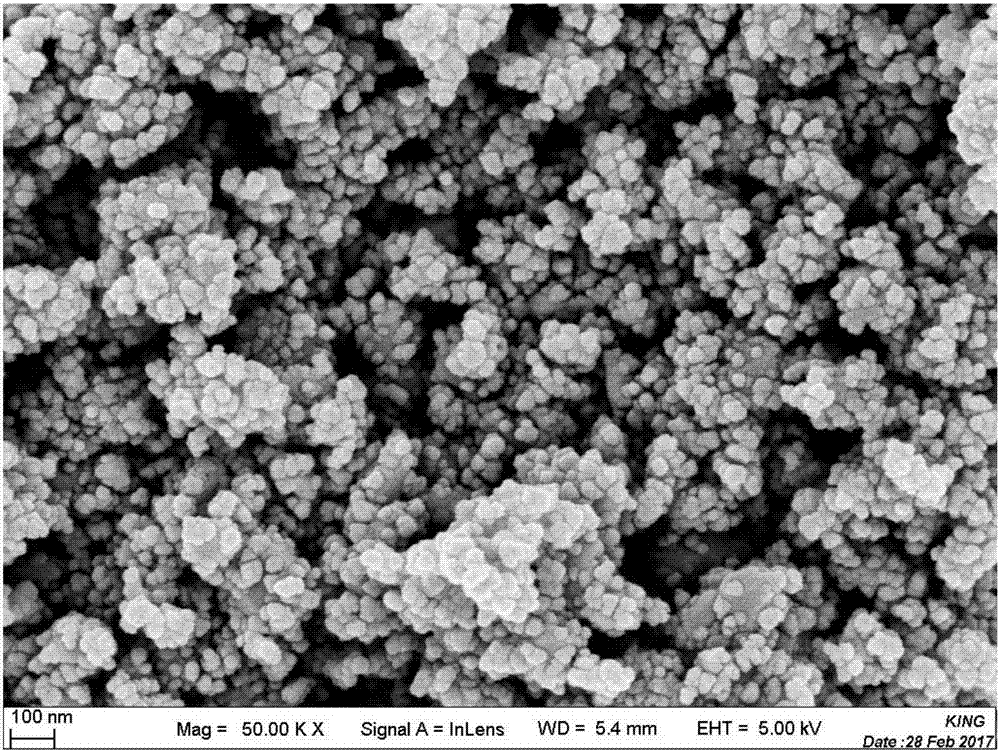

[0032] (4) The powder solid obtained after heating is separated in a magnetic field, and then the magnetic powder is washed and dried to obtain black NiFe 2 o 4 Catalyst particles, NiFe 2 o 4 The diameter is 20-30nm;

[0033] Ⅱ)NiFe 2 o 4 / Cu 2 Preparation of O magnetic composites:

[0034] (1) At 35°C, stir and dissolve 3.993g of copper acetate he...

Embodiment 2

[0040] A NiFe 2 o 4 / Cu 2 The preparation method of O magnetic composite nano-catalyst, it may further comprise the steps:

[0041] Ⅰ)NiFe 2 o 4 Preparation of:

[0042] (1) taking by weighing nickel chloride hexahydrate and iron trichloride hexahydrate respectively as 2:1.5 by the mol ratio of iron and nickel and being dissolved in deionized water;

[0043] (2) Add sodium hydroxide solution dropwise to the mixed solution to adjust the pH value to 10, and heat the mixed solution to 80° C. for 3.5 hours;

[0044] (3) Transfer the heated solution to the reactor, heat the reactor to 800°C and keep it warm for 2.5h;

[0045] (4) The powder solid obtained after heating is separated in a magnetic field, and then the magnetic powder is washed and dried to obtain black NiFe 2 o 4 Catalyst particles, NiFe 2 o 4 The diameter is 20-30nm;

[0046] Ⅱ)NiFe 2 o 4 / Cu 2 Preparation of O magnetic composites:

[0047] (1) At 35°C, stir and dissolve 3.993g of copper acetate hexahy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com