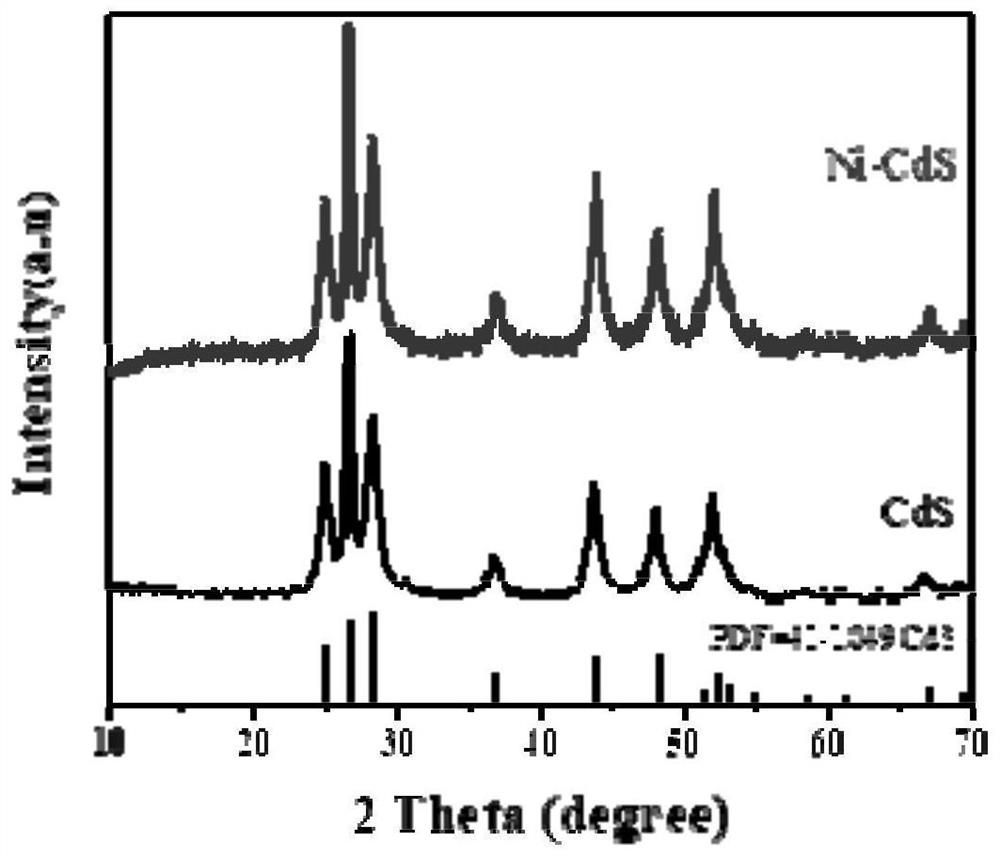

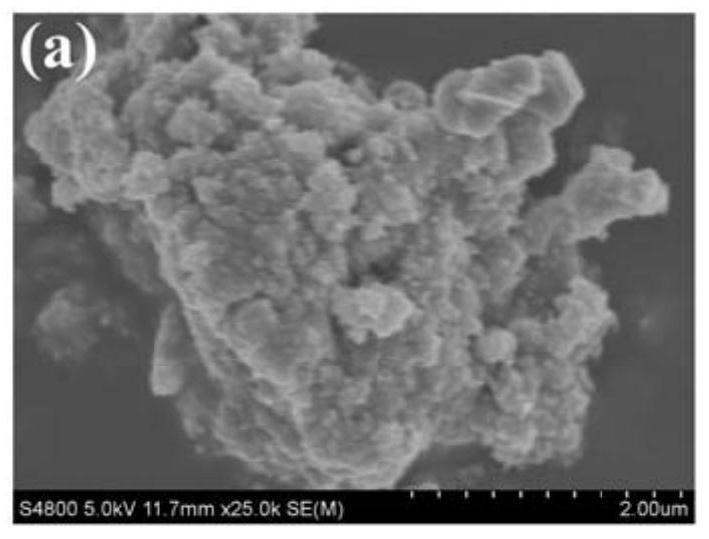

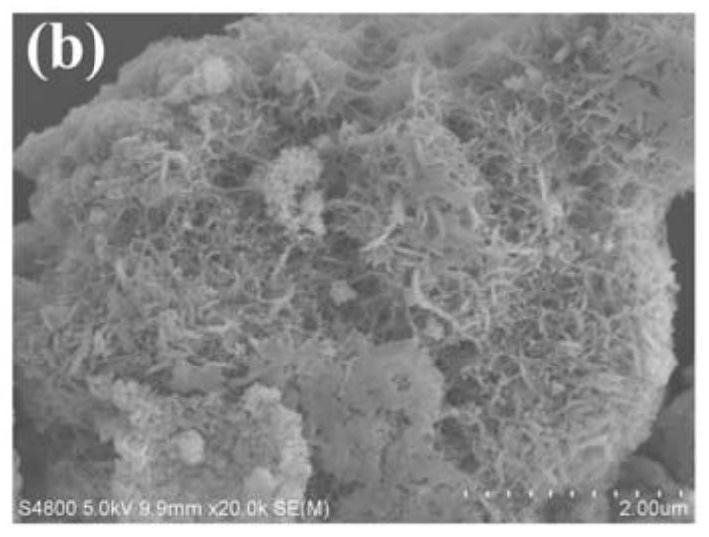

Hydrothermally synthesized Ni-doped CdS composite photocatalyst as well as preparation method and application thereof

A technology of hydrothermal synthesis and composite light, which is applied in the field of photocatalytic materials, can solve the problems of unfavorable large-scale promotion and expensive precious metals, and achieve the effects of inhibiting photocorrosion, uniform appearance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A hydrothermal synthesis of Ni-doped CDS composite photocatalysts and preparation methods thereof, including the following steps:

[0031] Step 1, first, raw materials such as cadmium acetate, thiramide are weighed in accordance with the following molar ratio. C 4 Hide 6 CDO 4· 2h 2 O: ch 3 CSNH 2 = (0.5 ~ 0.9): (0.6 ~ 1.0).

[0032] Step 2, the capacity ratio of 60 ml of ethylenediamine and ethylene glycol is added to: (1 to 5): 1 is then stirred at a magnetic stirrer at a speed of 500 r / min ~ 800r / min. Transparent solution A after 0.5H ~ 2H.

[0033] Step 3, the above solution A was poured into the inner liner of the polytetrafluoroethylene, followed by fixing the inner liner in an outer extrapylide, and the fill ratio was controlled at 60%. The temperature was controlled at 160 ° C to 180 ° C, and the reaction time was controlled at 5 to 8 h. The reactor is then naturally cooled to room temperature.

[0034] Step 4, the hydrothermal reaction ends, and the reactor is ...

Embodiment 1

[0039] 1) First, raw materials such as cadmium acetate, thiramide are weighed in accordance with the following molar ratio.

[0040] C 4 Hide 6 CDO 4· 2h 2 O: ch 3 CSNH 2 = 0.5: 0.6

[0041] 2) The capacity ratio of the above-mentioned mixed material is added to the amount of ethylenediamine and ethylene glycol is: 1: 1, then the magnetic stirrer is stirred at a magnetic stirrer at a rate of 500 r / min to obtain a transparent solution A.

[0042] 3) Pour the above solution A into the liner of the polytetrafluoroethylene, followed by fixing the inner liner in an outer extract, and the fill ratio is controlled at 60%. The temperature was controlled at 160 ° C, and the reaction time was controlled at 8 h. The reactor is then naturally cooled to room temperature.

[0043] 4) End of the hydrothermal reaction, the reaction kettle was naturally cooled to room temperature, and then the reaction was poured out of the reaction after the reaction, and the product was collected after three w...

Embodiment 2

[0048] 1) First, raw materials such as cadmium acetate, thiramide are weighed in accordance with the following molar ratio.

[0049] C 4 Hide 6 CDO 4· 2h 2 O: ch 3 CSNH 2 = 0.6: 0.7.

[0050] 2) The capacity ratio of 60 ml of ethylenediamine and ethylene glycol is added to: 2: 1 and then stirred at a magnetic stirrer at a rate of 600 r / min for 1 h, and the transparent solution A is obtained.

[0051] 3) Pour the above solution A into the liner of the polytetrafluoroethylene, followed by fixing the inner liner in an outer extract, and the fill ratio is controlled at 60%. The temperature was controlled at 170 ° C, and the reaction time was controlled at 7h. The reactor is then naturally cooled to room temperature.

[0052] 4) The hydrothermal reaction ends, and the reaction kettle is naturally cooled to room temperature, and then the reaction after the reaction is fed out, and the product was collected after three water and three alternately filtration, and the product was dried u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com