Phosphorus-modified nickel cobaltate-modified carbon nanotube electrode catalyst

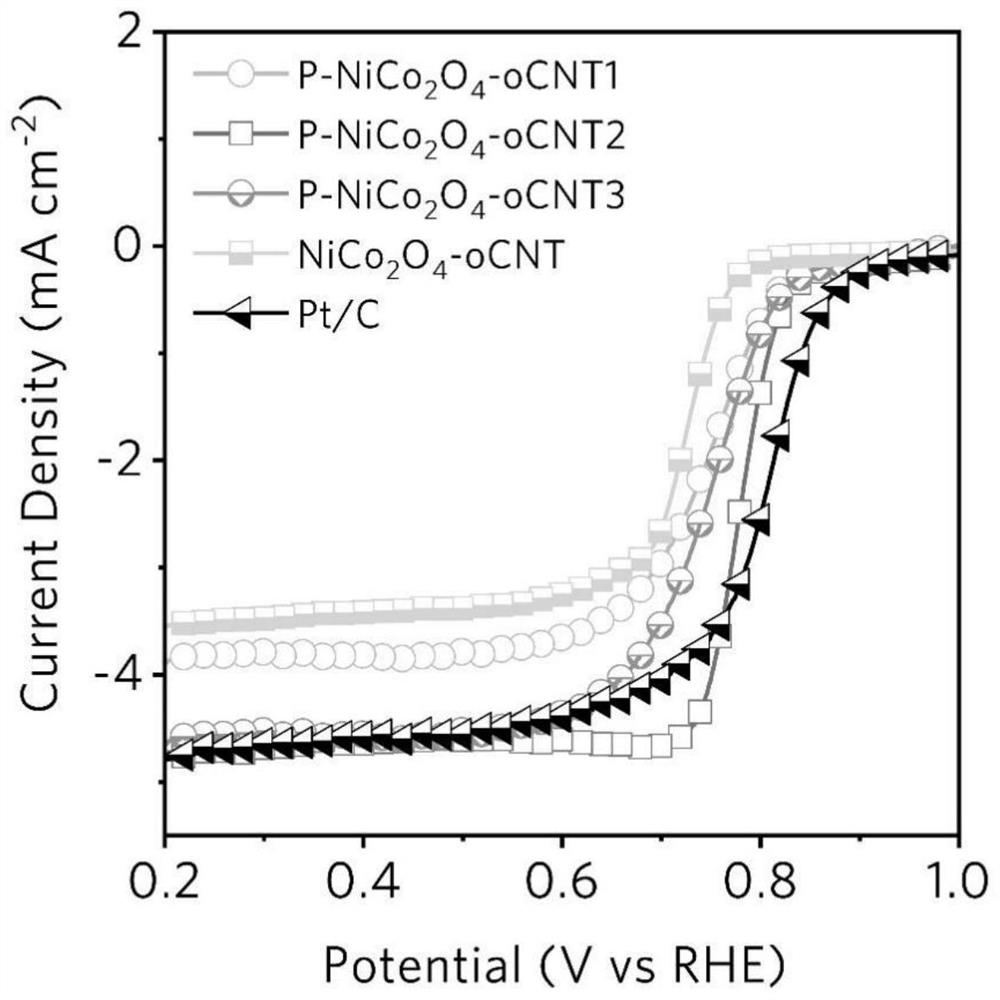

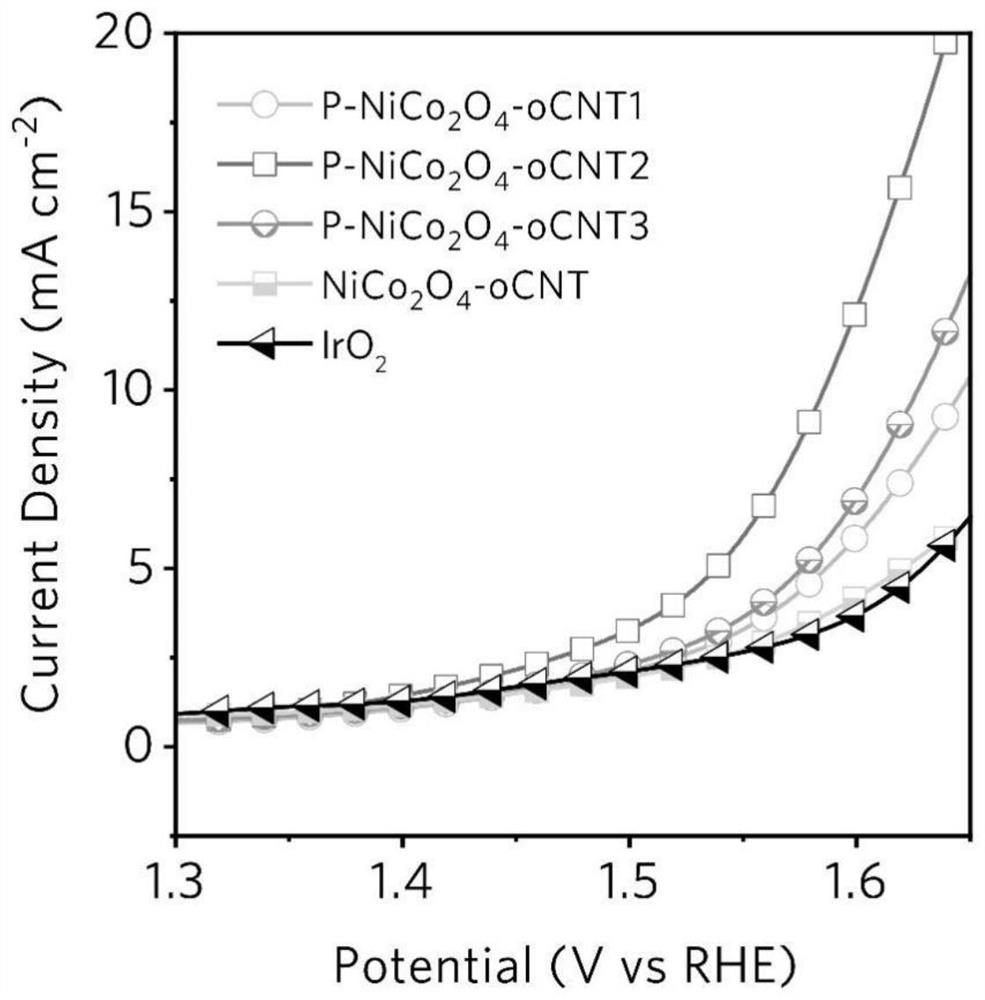

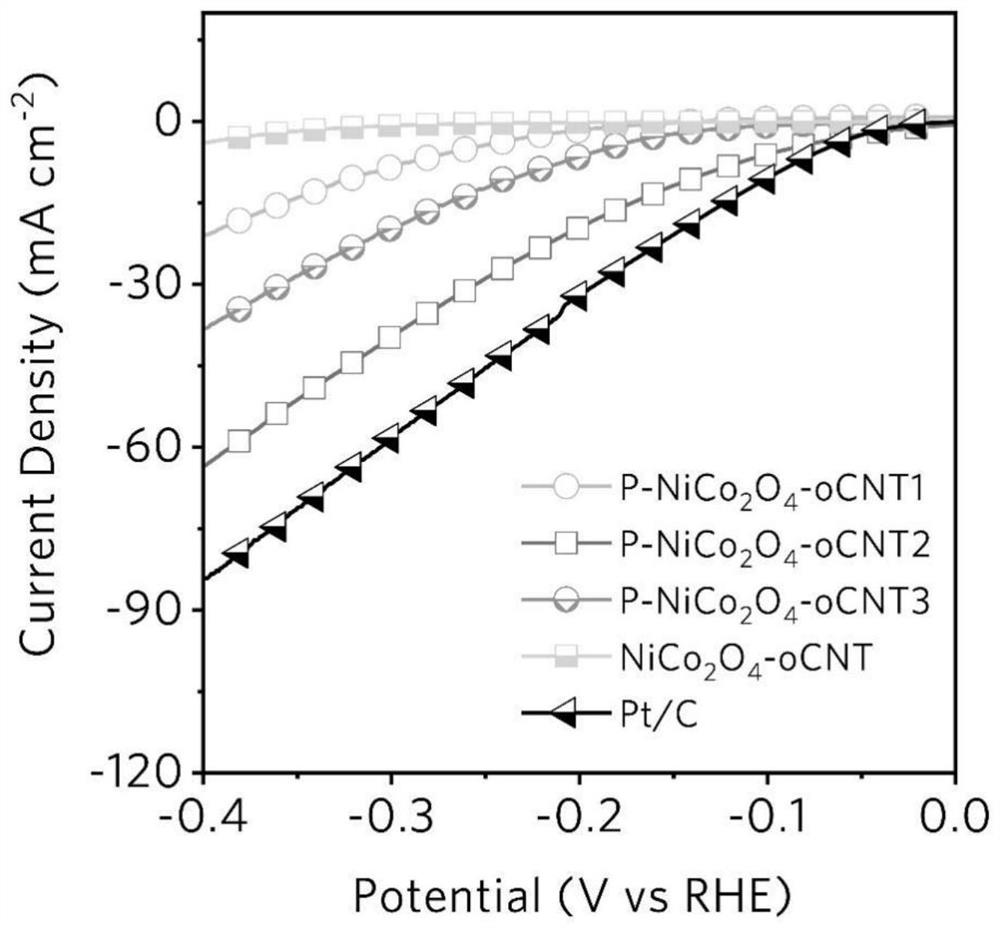

A technology of electrode catalysts and carbon nanotubes, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of low catalytic hydrogen evolution reaction activity and energy loss, and achieve efficient oxygen evolution reaction, high conductivity, and excellent long-term stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation of phosphorus-modified nickel cobaltate modified carbon nanotube electrode catalyst, comprises the following steps:

[0024] (1) Weigh 0.05g of hydroxyl carbon nanotube oCNT, 0.0476g (0.2mmol) of cobalt chloride hexahydrate and 0.0237g (0.1mmol) of nickel chloride hexahydrate in a 100mL reactor, then add 0.75mL of ammonia water and 70mL of absolute ethanol, followed by ultrasonication for 30min for dispersion and mixing.

[0025] (2) Put the reaction kettle in an oven at 140°C for 16 hours for heat treatment, then wait for room temperature, filter, wash and dry in an oven at 50°C for 4 hours to obtain a black powder.

[0026] (3) Put the above-mentioned black powder in a porcelain boat and move it to a tube furnace, place a porcelain boat filled with 100 mg of sodium hypophosphite at the air inlet, feed nitrogen as a protective gas, and heat up at a rate of 8°C / min The rate is increased to 600° C. and maintained for 2 hours, and the phosphorus-mod...

Embodiment 2

[0028] Place the porcelain boat that fills 200mg sodium hypophosphite at the air inlet; Other preparation process and parameter are identical with embodiment 1; Sample mark is P-NiCo 2 o 4 -oCNT-2.

Embodiment 3

[0030] Place the porcelain boat that fills 300mg sodium hypophosphite at the air inlet; Other preparation process and parameter are identical with embodiment 1; Sample mark is P-NiCo 2 o 4 -oCNT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com