Preparation method of supercapacitor electrode material

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. Effects of Diffusion and Transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]The preparation method of the supercapacitor electrode material of the present invention includes the following steps:

[0036]1. Preparation of active materials (Ni-MOF): 1 addition of hexahydraminated nickel chloride (NICL) in a mixed solution containing ethanol, deionized water and N, N-dimethylformamide (DMF).2• 6h2O) and terephthalic acid (PTA), then rapid addition of triethylamine (TEA) and stirred and stirred, forming a colloid suspension;

[0037]Further treatment of colloidal suspension chamber: Ultrasound treatment, centrifugal collection product, vacuum drying after ethanol, to obtain active materials, spare;

[0038]In mixed solution of ethanol, deionized water and N, N-dimethylformamide, the volume ratio of three components can be: 1: (0.8-1.5): (12-20), such as 2ml: 2ml: 30ml Wait.

[0039]2, the production of Ni-MOF electrodes: 1) Pretreatment foam nickel: Cropped foam nickel into rectangles that meet process requirements, such as 1 × 3 cm2After mixing with ethanol and deio...

Embodiment 1

[0053]A) Preparation of active materials (Ni-MOF): 0.75 mmol of hexahydrachlorinated nickel (NICL2• 6h2O) and 0.75 mmol of terephthalic acid (PTA) were dissolved in a mixed solution containing 2 mL ethanol, 2 mL deionized water and 30 ml n, N-dimethylformamide (DMF), and then 0.8 ML triethylamine (TEA) rapidly poured into the above mixed solution and stirred for a period of time, such as 5 min, resulting in a colloidal suspension. The final product was collected by centrifugation at room temperature, and the final product was collected by centrifugation; and the final product ethanol was washed with EtOAc. 12 h.

[0054]B) Production of Ni-MOF electrode: cut foam nickel to 1 × 3 cm2The rectangular infiltration into the HCl of 3 m, ethanol and deionized water multiple times, after drying, after drying at 60 ° C, it is dry after drying.

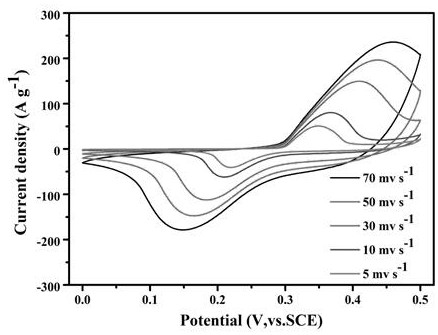

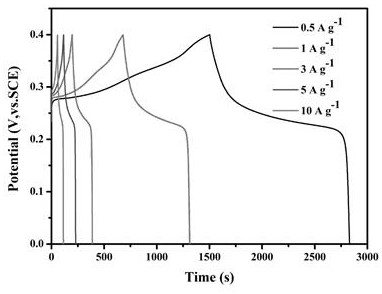

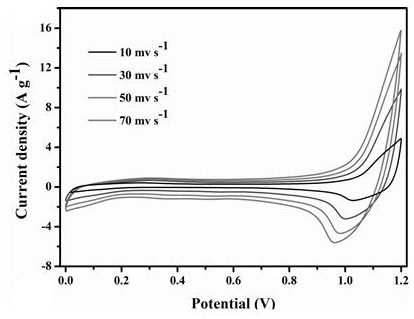

[0055]The preparation process of the electrode sheet is as follows: the active material, the conductive carbon black and polyvinylidene fluoride (PVDF) ar...

Embodiment 2

[0057]A) Preparation of active materials (Ni-MOF): 0.75 mmol of hexahydrachlorinated nickel (NICL2• 6h2O) and 0.75 mmol of terephthalic acid (PTA) were dissolved in a mixed solution containing 2 mL ethanol, 2 mL deionized water and 30 mL N, N-dimethylformamide (DMF). 0.8 ml of triethylamine (TEA) was quickly poured into the mixed solution and stirred for a period of time, such as 6min, resulting in a colloidal suspension. Ultrasonic treatment 4 h was collided at room temperature, and the final product was collected by centrifugation, and the final product ethanol was washed, and 12 h was dried in vacuo 80 ° C.

[0058]B) Production of Ni-MOF electrode: cut foam nickel to 1 × 3 cm2The rectangular infiltration into the HCl of 3 m, and then the amount is subjected to drying with ethanol and deionized water. The preparation flow of the electrode sheet is as follows: mixed the active material, the conductive carbon black, and the polyvinylidene fluoride (PVDF), and dissolved in N-methylpyrr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com