Nano-structure Ni-base composite electroplating solution containing nano Si3N4 particles and preparation method thereof

A composite electroplating and nanostructure technology, which is applied in the fields of electrochemistry and metal surface treatment, can solve the problems of high cost, high pollution hardness, etc., and achieve the effects of excellent corrosion resistance, reduced coating thickness, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

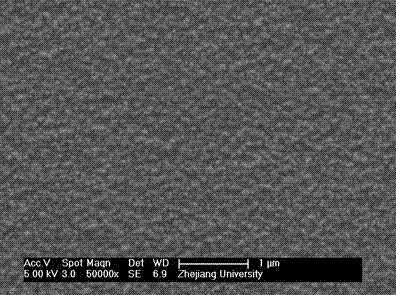

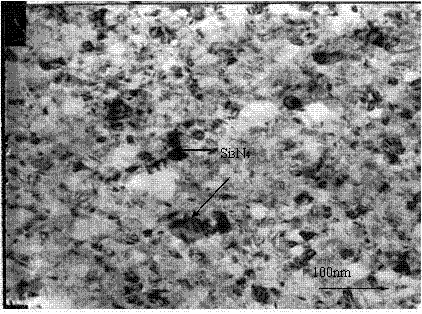

[0042] A nano-Si 3 N 4 The preparation method of the nanostructure Ni base composite thin film material of particle, this method comprises the following steps:

[0043] (1) Nano Si 3 N 4 Surface chemical modification before particle plating

[0044] Nano-Si 3 N 4 The particles were surface chemically modified in sodium lauryl sulfate solution at the following ratio: per 1 gram of Si 3 N 4 The particles were dispersed in 4 liters of sodium dodecyl sulfate solution with a concentration of 1.2 g / L, and then ultrasonically dispersed for 3 hours to carry out surface chemical modification before plating.

[0045] (2) Configuration of composite plating solution

[0046] The concentration of each component of the electroplating solution is as follows: nickel sulfate hexahydrate 200g / L; nickel chloride hexahydrate 48g / L; boric acid 45g / L; sodium lauryl sulfate 1.7g / L; 1-4 butynediol 0.4g / L; sodium allyl sulfonate is 0.6g / L, sodium propyne sulfonate is 0.8g / L; the above electro...

Embodiment 2

[0058] A nano-Si 3 N 4 The preparation method of the nanostructure Ni base composite thin film material of particle, this method comprises the following steps:

[0059] (1) Nano Si 3 N 4 Surface chemical modification before particle plating

[0060] Nano-Si 3 N 4 The particles were surface chemically modified in sodium lauryl sulfate solution at the following ratio: per 1 gram of Si 3 N 4 The particles were dispersed in 4 liters of sodium lauryl sulfate solution, the concentration of the sodium lauryl sulfate solution was 1.5 g / L, and then ultrasonic dispersion was used for 4 hours to carry out surface chemical modification before plating.

[0061] (2) Configuration of composite plating solution

[0062] The concentration of each component of the electroplating solution is as follows: nickel sulfate hexahydrate 180g / L; nickel chloride hexahydrate 55g / L; boric acid 50g / L; sodium lauryl sulfate 1.7g / L; 1-4 butynediol 0.4g / L; sodium allyl sulfonate is 0.8g / L, sodium prop...

Embodiment 3

[0074] A nano-Si 3 N 4 The preparation method of the nanostructure Ni base composite thin film material of particle, this method comprises the following steps:

[0075] (1) Nano Si 3 N 4 Surface chemical modification before particle plating

[0076] Nano-Si 3 N 4 The particles were surface chemically modified in sodium lauryl sulfate solution at the following ratio: per 1 gram of Si 3 N 4 The particles were dispersed in 6 liters of sodium lauryl sulfate solution, the concentration of the sodium lauryl sulfate solution was 0.8g / L, and then ultrasonic dispersion was used for 3 hours to carry out surface chemical modification before plating.

[0077] (2) Configuration of composite plating solution

[0078] The concentration of each component of the electroplating solution is as follows: nickel sulfate hexahydrate 220g / L; nickel chloride hexahydrate 45g / L; boric acid 50g / L; sodium lauryl sulfate 1.7g / L; 1-4 butynediol 0.4g / L; sodium allyl sulfonate is 1.2g / L, sodium propy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com