Platinum monatomic catalyst and preparation method and application thereof

A catalyst and atomic technology, applied in the direction of electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of harsh preparation conditions, difficulty in mass production of catalysts, and low loading capacity, and achieve mild and simple preparation methods, high utilization of precious metals, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]A preparation method of a platinum single-atom catalyst, comprising the steps of:

[0040] Step S1, dissolving the oxidized carbon nanotubes in deionized water from which oxygen has been removed;

[0041] Specifically, the process for oxidation treatment of carbon nanotubes is as follows:

[0042] Dissolve carbon nanotubes, potassium nitrate, and potassium permanganate into concentrated sulfuric acid, add an appropriate amount of deionized water after a period of reaction, and ensure that the temperature does not exceed 80°C during the dropping process, and then add an appropriate amount of hydrogen peroxide, and the reaction will be stable. After a period of time, the solution is washed to neutrality, and then freeze-dried to obtain oxidized carbon nanotubes;

[0043] The amount of carbon nanotubes to be oxidized is to dissolve 0.2-1mg of carbon nanotubes in 1ml of deionized water, and adopt an ultrasonic dispersion process to obtain a uniformly dispersed carbon nanotu...

Embodiment 1

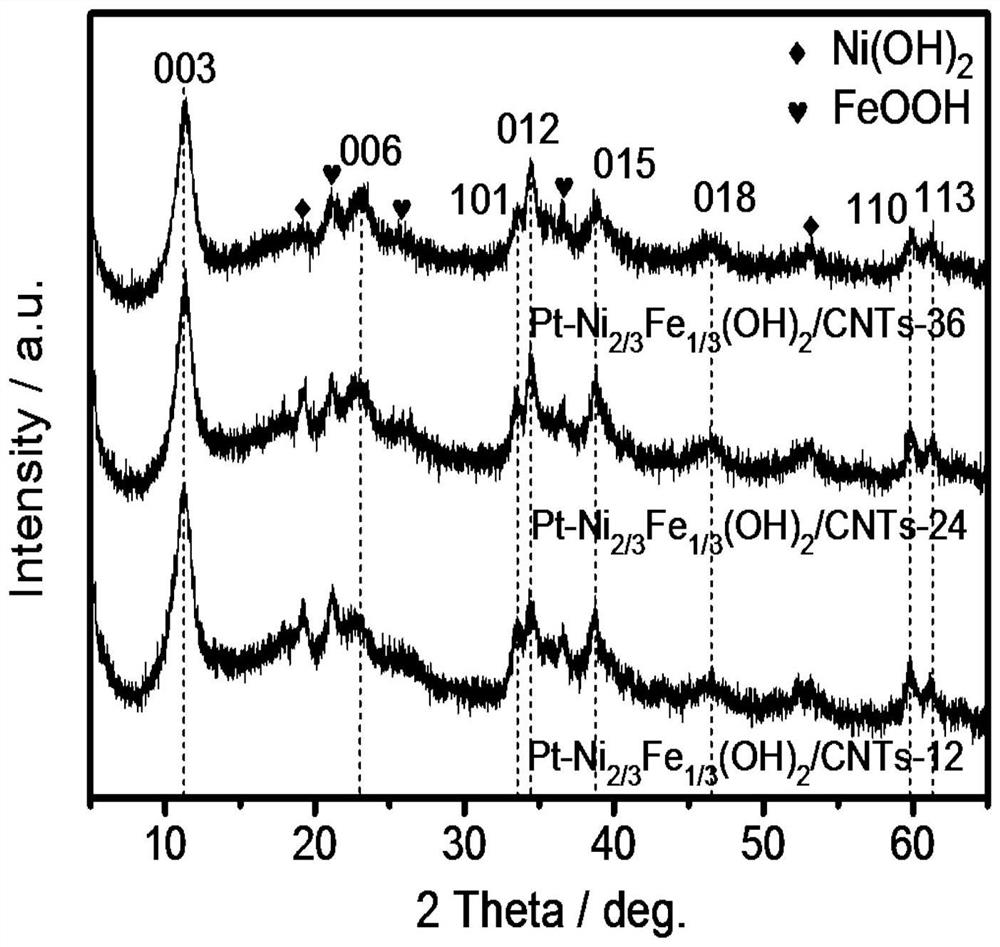

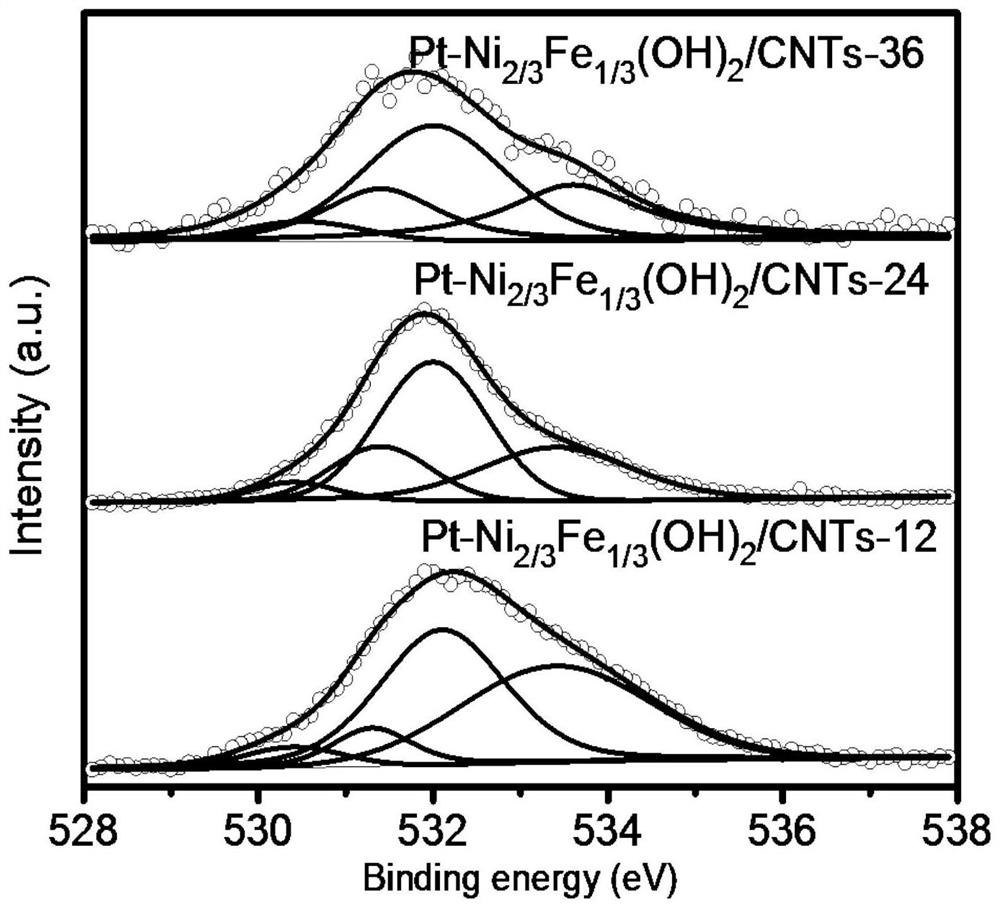

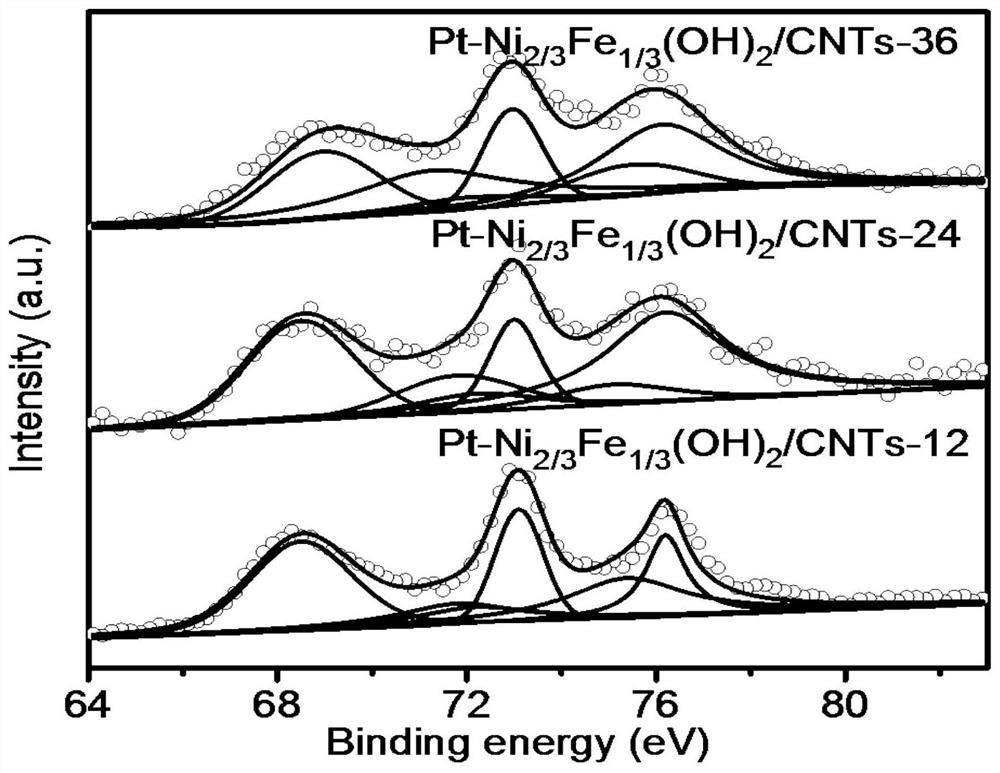

[0052] Weigh 1g of carbon nanotubes, 0.3g of potassium nitrate and 1g of potassium permanganate and dissolve them in 50ml of concentrated sulfuric acid. After reacting for 6 hours, add 230ml of deionized water. During the dropping process, ensure that the temperature does not exceed 80°C, and then add 2ml of hydrogen peroxide, reacted for 1 hour, washed the solution until neutral, and finally freeze-dried to obtain oxidized carbon nanotubes. Weigh 10 mg of oxidized carbon nanotubes and dissolve them in 40 ml of deionized water that has been passed through nitrogen gas for 30 minutes, and ultrasonically disperse for 30 minutes to obtain a uniformly dispersed carbon nanotube solution. Then weigh the hexamethylenetetramine of 2mmol, the ammonium fluoride of 0.6mmol, the nickel chloride hexahydrate of 0.2mmol, the ferrous chloride tetrahydrate of 0.1mmol, and the uniformly dispersed carbon nanotube solution are added together In a 100ml reactor, react at 120°C for 6h, filter and w...

Embodiment 2

[0054] Weigh 1g of carbon nanotubes, 0.3g of potassium nitrate and 1g of potassium permanganate and dissolve them in 50ml of concentrated sulfuric acid. After reacting for 6 hours, add 230ml of deionized water. During the dropping process, ensure that the temperature does not exceed 80°C, and then add 2ml of hydrogen peroxide, reacted for 1 hour, washed the solution until neutral, and finally freeze-dried to obtain oxidized carbon nanotubes. Weigh 10 mg of oxidized carbon nanotubes and dissolve them in 40 ml of deionized water that has been passed through nitrogen gas for 30 minutes, and ultrasonically disperse for 30 minutes to obtain a uniformly dispersed carbon nanotube solution. Then weigh the hexamethylenetetramine of 2mmol, the ammonium fluoride of 0.6mmol, the nickel chloride hexahydrate of 0.2mmol, the ferrous chloride tetrahydrate of 0.1mmol, and the uniformly dispersed carbon nanotube solution are added together In a 100ml reactor, react at 120°C for 6h, filter and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com