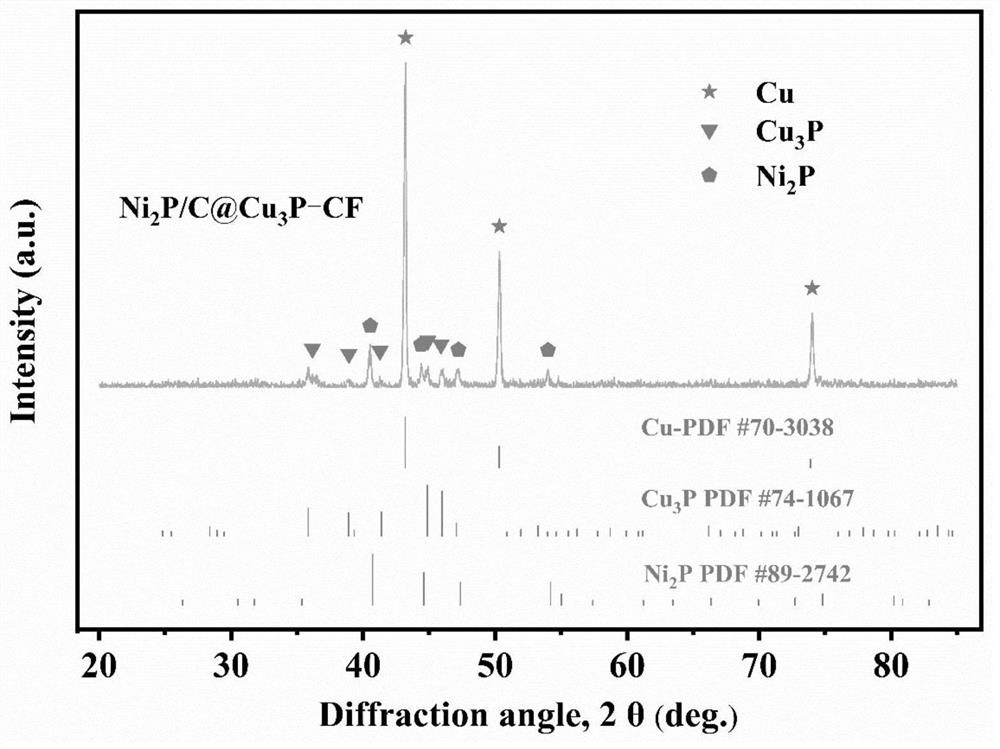

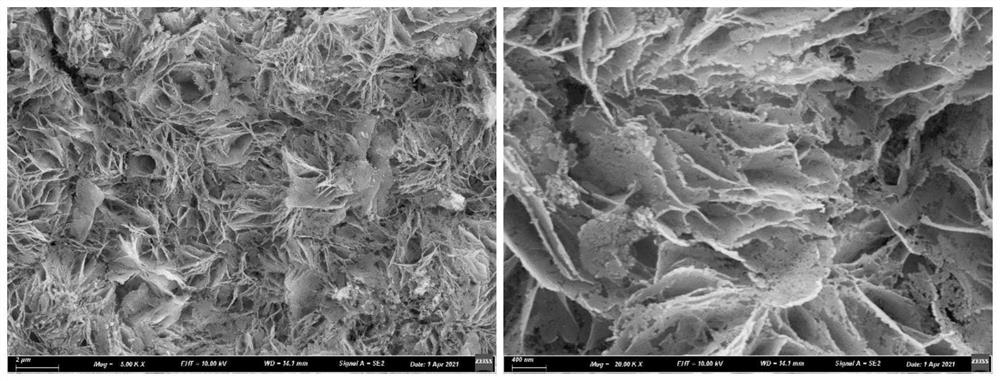

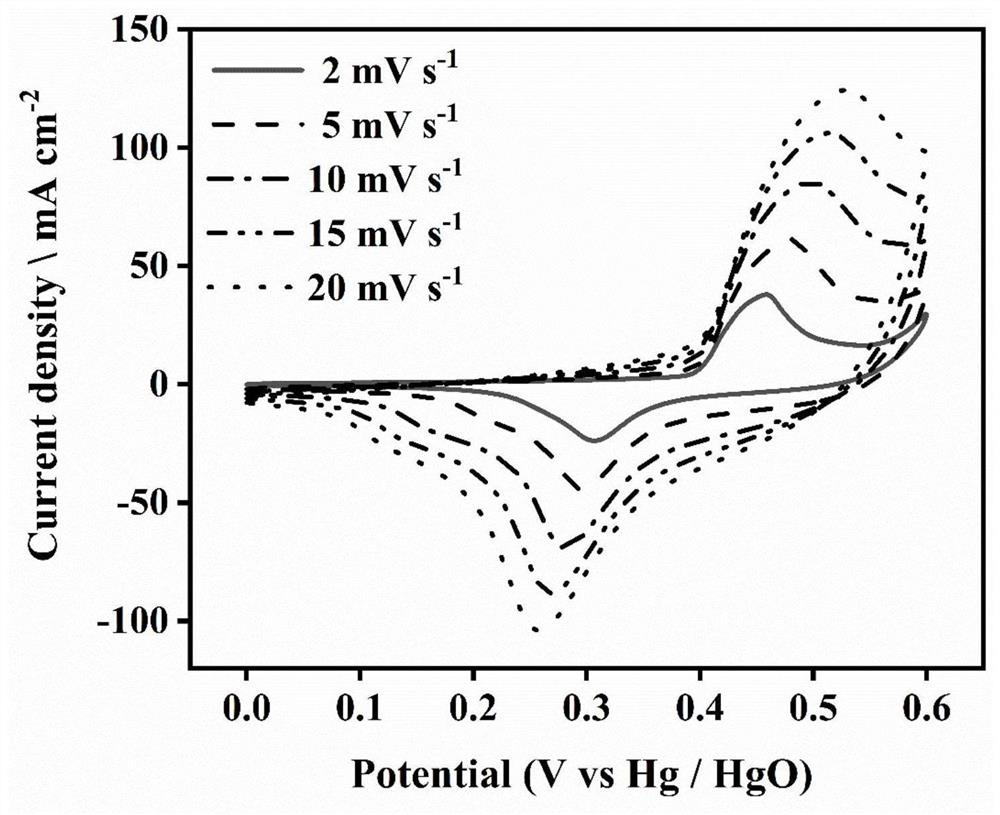

MOF-derived porous metal phosphide nanosheet array and application

An in-situ growth, foamed copper technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long charging time, large energy loss, low durability, etc., to achieve large capacity , good rate performance, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Cut the copper foam into a suitable size (1×3cm 2 ) Clean the surface with a degreasing liquid, the degreasing liquid is an acetone solution, and ultrasonically clean it in an ultrasonic cleaning machine at room temperature for 30 minutes to wash away the surface lipid. In order to wash away impurities such as oxides on the surface of foamed copper after degreasing, it needs to be transferred into an acid solution (2 M HCl), increase the active sites of foamed copper at the same time, and then ultrasonically clean at room temperature for 15 minutes to remove the copper oxide on the surface. After taking it out, wash it several times with a large amount of deionized water and dry it in a vacuum oven for use.

[0026] (2) 2mmol of NiCl 2 ·6H 2 O and 2mmol of terephthalic acid (PTA) were added to the Erlenmeyer flask, and then 40ml of N,N-dimethylformamide (DMF) was added to the magnetic sub and stirred on a magnetic stirrer for 30min. Use a burette to slowly add 2...

Embodiment 2

[0030] (1) Cut the copper foam into a suitable size (1×3cm 2 ) Clean the surface with a degreasing liquid, the degreasing liquid is an acetone solution, and ultrasonically clean it in an ultrasonic cleaning machine at room temperature for 30 minutes to wash away the surface lipid. In order to wash away impurities such as oxides on the surface of foamed copper after degreasing, it needs to be transferred into an acid solution (2 M HCl), increase the active sites of foamed copper at the same time, and then ultrasonically clean at room temperature for 15 minutes to remove the copper oxide on the surface. After taking it out, wash it several times with a large amount of deionized water and dry it in a vacuum oven for use.

[0031] (2) 2mmol of NiCl 2 ·6H 2 O and 2mmol of terephthalic acid (PTA) were added to the Erlenmeyer flask, and then 40ml of N,N-dimethylformamide (DMF) was added to the magnetic sub and stirred on a magnetic stirrer for 30min. Use a burette to slowly add 2...

Embodiment 3

[0035] (1) Cut the copper foam to 4 times the size (4×3cm 2 ) Clean the surface with a degreasing liquid, the degreasing liquid is an acetone solution, and ultrasonically clean it in an ultrasonic cleaning machine at room temperature for 30 minutes to wash away the surface lipid. In order to wash away impurities such as oxides on the surface of foamed copper after degreasing, it needs to be transferred into an acid solution (2 M HCl), increase the active sites of foamed copper at the same time, and then ultrasonically clean at room temperature for 15 minutes to remove the copper oxide on the surface. After taking it out, wash it several times with a large amount of deionized water and dry it in a vacuum oven for use.

[0036] (2) 2mmol of NiCl 2 ·6H 2 O and 2mmol of terephthalic acid (PTA) were added to the Erlenmeyer flask, and then 40ml of N,N-dimethylformamide (DMF) was added to the magnetic sub and stirred on a magnetic stirrer for 30min. Use a burette to slowly add 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com