Preparation method of iron-doped nickel phosphide composite nitrogen-doped reduced graphene oxide electro-catalytic material

An electrocatalytic material and graphene technology, applied in the field of material chemistry, can solve the problems of low electrocatalytic water splitting performance and slow electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

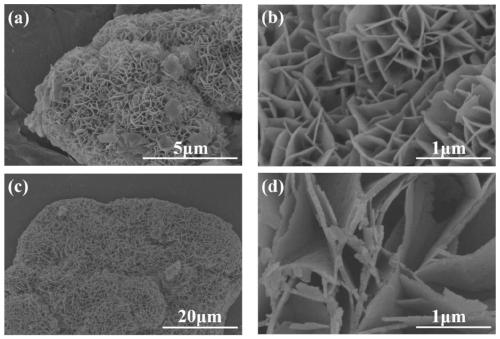

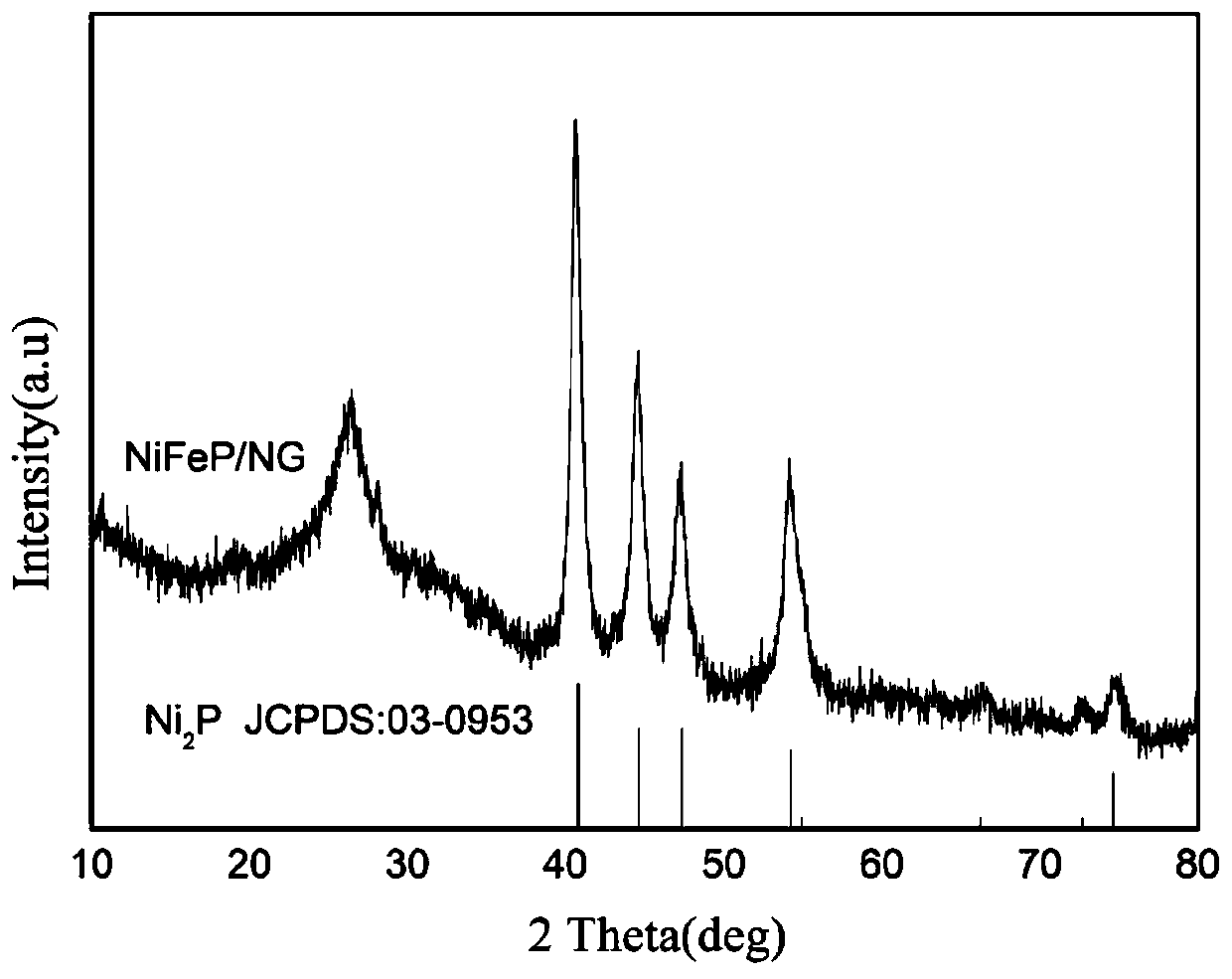

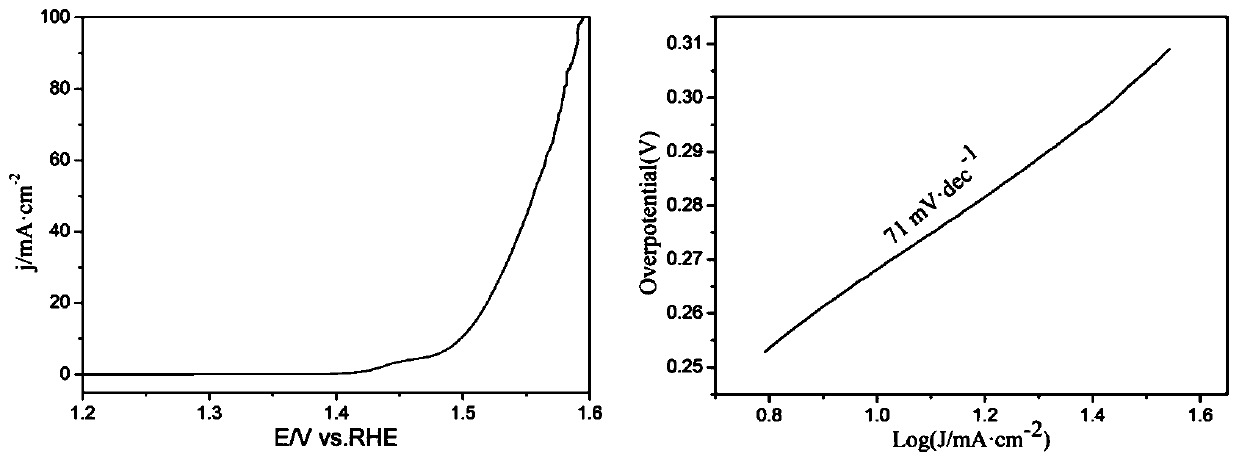

Image

Examples

Embodiment 1

[0021] (1) Preparation of nitrogen-doped reduced graphene oxide

[0022] (a) 300 mg of graphene oxide was dissolved in 300 mL of deionized water, 1.5 g of melamine was added after ultrasonication for 5 h, and a light black solid was obtained by stirring and evaporating;

[0023] (b) Place the light black solid obtained in (a) in a tube furnace, heat it to 800°C in an inert atmosphere, keep it warm for 1 hour, then cool it to room temperature with the furnace, wash and dry it, and obtain nitrogen-doped reduced graphene oxide.

[0024] (2) Preparation of NiFe-LDH / NG:

[0025] (a) Disperse the obtained 30 mg of nitrogen-doped reduced graphene oxide by ultrasound for 5 h in 35 mL of deionized water, and add 0.833 mmol of NiCl 2 ·6H 2 O, 0.166mmol FeSO 4 ·7H 2 O, 10mmol urea and 5mmol NH 4 F Stir to a homogeneously mixed solution;

[0026] (b) Transfer the solution in (a) to the reaction kettle, then react at 120°C for 8 hours, centrifuge to obtain a dark green precipitate, w...

Embodiment 2

[0031] (1) Preparation of nitrogen-doped reduced graphene oxide

[0032] (a) 300 mg of graphene oxide was dissolved in 300 mL of deionized water, 1.5 g of melamine was added after ultrasonication for 5 h, and a light black solid was obtained by stirring and evaporating;

[0033] (b) Place the light black solid obtained in (a) in a tube furnace, heat it to 800°C in an inert atmosphere, keep it warm for 1 hour, then cool it to room temperature with the furnace, wash and dry it, and obtain nitrogen-doped reduced graphene oxide.

[0034] (2) Preparation of NiFe-LDH / NG:

[0035] (a) Disperse the obtained 30 mg nitrogen-doped reduced graphene oxide ultrasonically for 5 h in 35 mL deionized water, add 0.667 mmol NiCl 2 ·6H 2 O, 0.333mmol FeSO4 7H 2 O, 10mmol urea and 5mmol NH F are stirred to a uniformly mixed solution;

[0036] (b) Transfer the solution in (a) to the reaction kettle, then react at 120°C for 8 hours, centrifuge to obtain a dark green precipitate, wash the precipi...

Embodiment 3

[0041] (1) Preparation of nitrogen-doped reduced graphene oxide

[0042] (a) 300 mg of graphene oxide was dissolved in 300 mL of deionized water, 1.5 g of melamine was added after ultrasonication for 5 h, and a light black solid was obtained by stirring and evaporating;

[0043] (b) Place the light black solid obtained in (a) in a tube furnace, heat it to 800°C in an inert atmosphere, keep it warm for 1 hour, then cool it to room temperature with the furnace, wash and dry it, and obtain nitrogen-doped reduced graphene oxide.

[0044] (2) Preparation of NiFe-LDH / NG:

[0045] (a) Disperse 30 mg of nitrogen-doped reduced graphene oxide obtained by ultrasonication for 5 h in 35 mL of deionized water, and add 0.889 mmol of NiCl 2 ·6H 2 O, 0.111mmol FeSO4 7H 2 O, 10mmol urea and 5mmol NH F are stirred to a uniformly mixed solution;

[0046] (b) Transfer the solution in (a) to the reaction kettle, then react at 120°C for 8 hours, centrifuge to obtain a dark green precipitate, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com