Preparation method for Ni-Co/carbon nanotube aerogel catalyst of zinc-air battery

A carbon nanotube, zinc-air battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of restricting the application and development of zinc-air batteries, high price, poor stability, etc., and achieve high product quality and safety. , the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

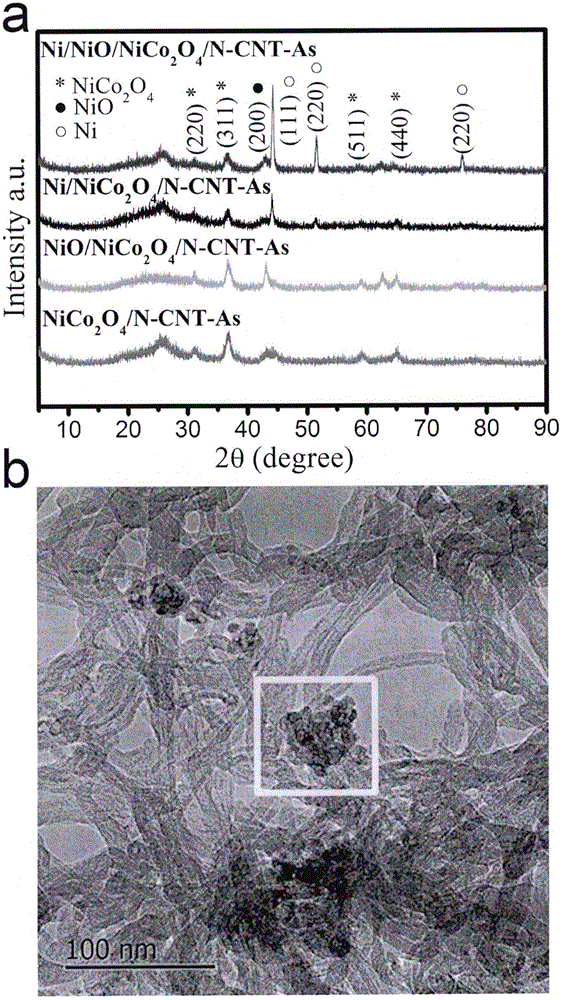

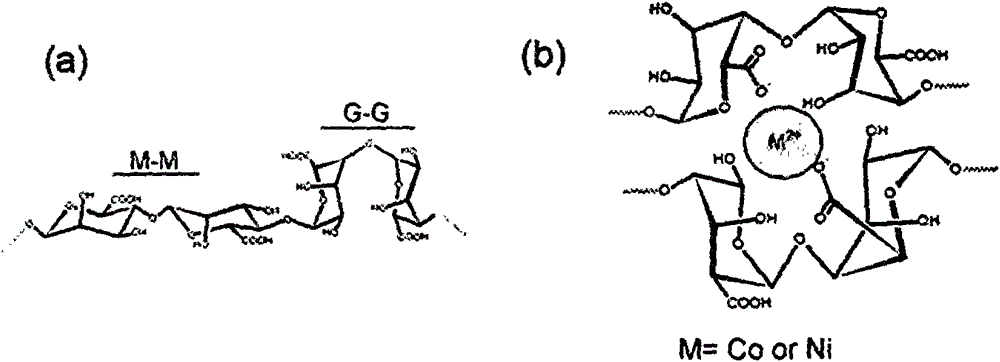

[0026] Dissolve 0.404 g of sodium alginate in 40 g of secondary deionized aqueous solution and stir for 6 hours to obtain a uniformly mixed 1 wt % sodium alginate solution, which is designated as solution 1. 0.0161 g of carbon nanotubes was mixed into the sodium alginate solution prepared above, and stirred for 6 hours to obtain a mixed solution of sodium alginate carbon nanotubes, which was designated as solution 2. Dissolve 1.3 g of nickel chloride hexahydrate and 1.3 g of cobalt chloride hexahydrate in 50 g of secondary deionized aqueous solution to obtain a mixed solution of nickel chloride and cobalt chloride, which is designated as solution 3. Drop solution 2 into the mixed solution of nickel chloride and cobalt chloride, that is, solution 3, to form a hydrogel of nickel-cobalt alginate carbon nanotubes. After the drop is completed, let it stand for 2 hours. The nickel-cobalt alginate carbon nanotube gel obtained above was separated, and washed with secondary deionized w...

Embodiment 2

[0028] In addition to mixing 0.1616g of carbon nanotubes into the sodium alginate solution prepared above and stirring for 6 hours, a mixed solution of sodium alginate carbon nanotubes was obtained, which was designated as solution 2. All the other steps are identical to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com