Flexible light and thin carbon cloth composite material with high electromagnetic shielding performance and preparation method thereof

A technology of electromagnetic shielding and composite materials, applied in the fields of magnetic field/electric field shielding, electrical components, heating/cooling fabrics, etc., can solve the problems of common conductivity, low hardness, and high hardness, and achieve low square resistance, good flexibility, and density. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Using impregnation method and carbonization process to prepare flexible, thin and high electromagnetic shielding performance carbon cloth composite material:

[0023] (a) Pretreatment of cotton fabric: soak the cotton fabric in 15g / L NaOH solution and boil for 1 hour to remove the pulp and impurities on the surface of the cotton fabric, then rinse it with ultrapure water for several times until it is neutral, then put it in an oven Dry at 60℃ for 1h;

[0024] (b) Surface modification of cotton fabrics: The cotton fabrics treated in (a) were immersed in 1 wt% hydroxypropyl-beta-cyclodextrin solution for 2 h, wherein hydroxypropyl-beta-cyclodextrin was dissolved in N-N - In dimethylformamide, the surface of the pretreated cotton fabric is further modified;

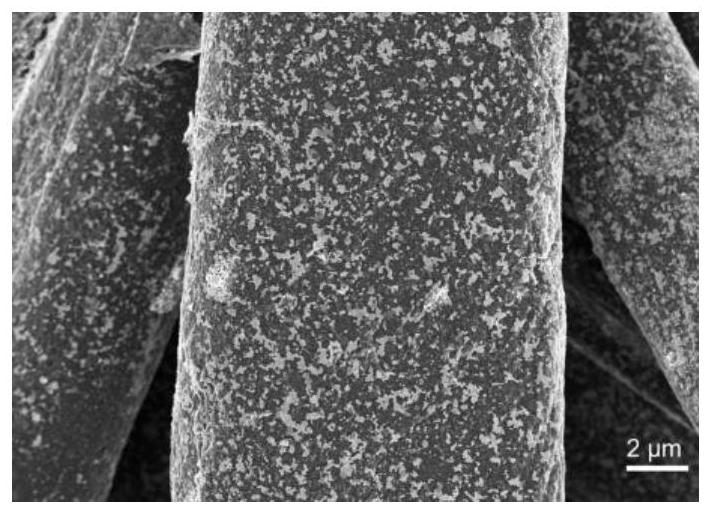

[0025] (c) Preparation of nickel-loaded carbonized cotton fabric: soak the modified cotton fabric in a solution of nickel chloride hexahydrate with a concentration of 1 mol / L for 24 h, and then dry it at 60 °C for...

Embodiment 2

[0040] a. Using carbonization process to prepare flexible and thin electromagnetic shielding material:

[0041] (a) Pretreatment of cotton fabric: soak the cotton fabric in 15g / L NaOH solution and boil for 1 hour to remove the pulp and impurities on the surface of the cotton fabric, then rinse it with ultrapure water for several times until it is neutral, then put it in an oven Dry at 60℃ for 1h;

[0042] (b) Preparation of carbonized cotton fabric: The treated cotton fabric was cut into 4*4 cm and calcined at 900 °C for 1 h in an argon atmosphere to prepare a flexible, light and thin composite carbon fabric.

[0043] b. Electromagnetic shielding performance test

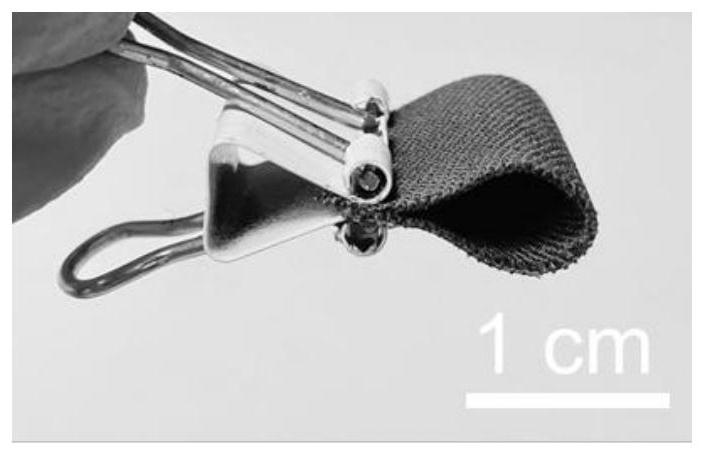

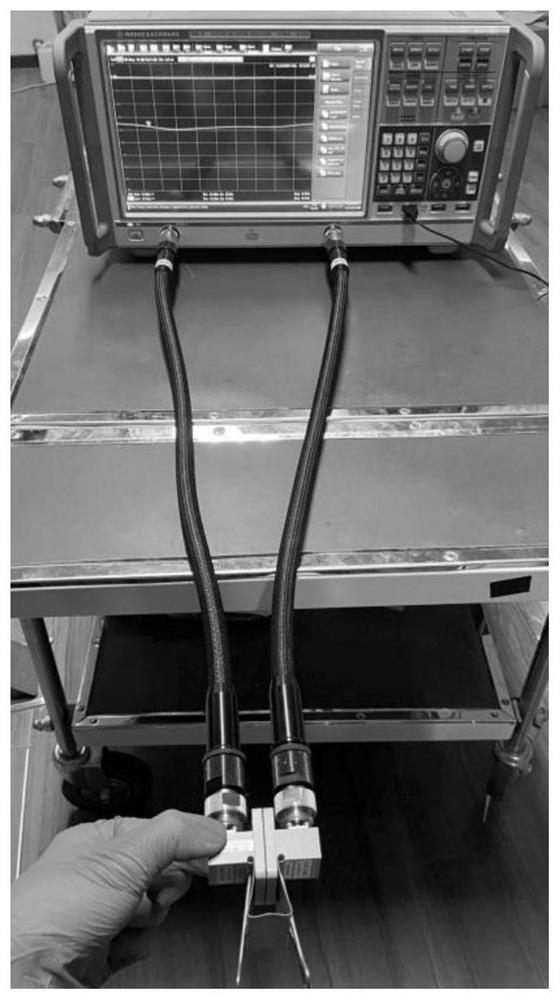

[0044]Based on the waveguide method, the S-parameter test of the carbon cloth is carried out with a vector network analyzer in the frequency range of 12GHz to 18GHz. The specific process of the test is as follows: figure 2 shown. Knowing the S-parameters can be calculated:

[0045] R=|S 11 | 2 =|S 22 | 2 (...

Embodiment 3

[0057] Change the loading of flexible electromagnetic shielding material nickel

[0058] a. Using impregnation method and carbonization process to prepare flexible, thin and high electromagnetic shielding performance carbon cloth composite material:

[0059] (a) Pretreatment of cotton fabric: soak the cotton fabric in 15g / L NaOH solution and boil for 1 hour to remove the pulp and impurities on the surface of the cotton fabric, then rinse it with ultrapure water for several times until it is neutral, then put it in an oven Dry at 60℃ for 1h;

[0060] (b) Surface modification of cotton fabrics: The cotton fabrics treated in (a) were immersed in 1 wt% hydroxypropyl-beta-cyclodextrin solution for 2 h, wherein hydroxypropyl-beta-cyclodextrin was dissolved in N-N - In dimethylformamide, the surface of the pretreated cotton fabric is further modified;

[0061] (c) Preparation of nickel-loaded carbonized cotton fabric: The modified cotton fabric was soaked in a solution of nickel ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com