Preparation method of isolated thermoplastic elastomer composite microporous electromagnetic shielding material

A thermoplastic elastomer, electromagnetic shielding material technology, applied in the fields of magnetic/electric field shielding, electrical components, bulk chemical production, etc. The problem of increasing the stiffness of polymer matrix composites has achieved the effect of improving electromagnetic shielding efficiency, good application prospects, and simple and efficient preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing an isolated thermoplastic elastomer composite microporous electromagnetic shielding material of the present invention specifically comprises the following steps:

[0025] Step 1: Add 1-2g of MAX-phase ceramic powder with a mesh size of 200-400 to a mixed solution of 20-40mL hydrochloric acid and 1-2g lithium fluoride, stir at 35°C for 24 hours to obtain a black solution, wash, centrifuge and ultrasonicate Stripped to get dark green Ti 3 C 2 T x MXene aqueous dispersion; Ti 3 C 2 T x Ti in MXene aqueous dispersion 3 C 2 T x The size of the MXene sheet is 100-300nm, and the concentration of the dispersion is 5-20mg / mL;

[0026] Step 2, place the thermoplastic elastomer beads in a supercritical CO 2 Carry out saturated absorption in an autoclave for 3-6 hours, the saturation temperature is 35-60°C, the saturation pressure is 8-20MPa, and then the fully saturated thermoplastic elastomer beads are placed in a high-temperature foaming device...

Embodiment 1

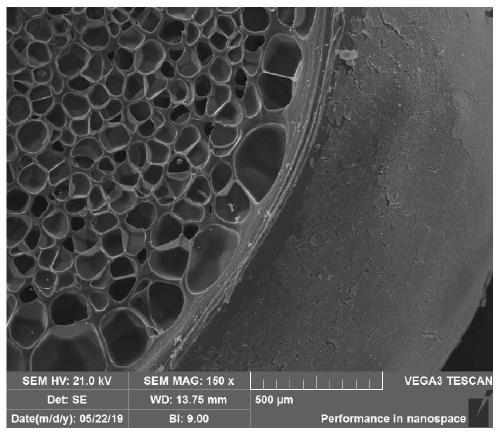

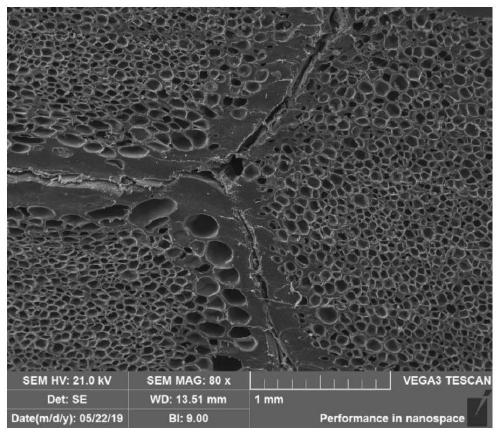

[0031] Weigh Ti with a concentration of 5 mg / mL 3 C 2 T x MXene aqueous dispersion 10mL, ultrasonic dispersion uniform; nylon 66 thermoplastic elastomer beads placed in a critical CO 2 Carry out saturated absorption in an autoclave for 3 hours, the saturation temperature is 35°C, and the saturation pressure is 8MPa, and then the fully saturated thermoplastic elastomer beads are placed in a high-temperature oil bath for microcellular foaming, and the foaming temperature is 100°C. The foaming time was 5s to obtain nylon 66 microporous foam beads; the microporous foam beads were immersed in Ti 3 C 2 T x MXene aqueous dispersion, after taking it out, place it in a 30°C oven for drying to obtain Ti 3 C 2 T x MXene-wrapped nylon 66 thermoplastic elastomer composite microporous beads; the resulting Ti 3 C 2 T x MXene-wrapped thermoplastic elastomer composite microporous beads were placed in the mold, poured formic acid at a temperature of 30°C to dissolve the surface of...

Embodiment 2

[0033] Weigh Ti at a concentration of 10mg / mL 3 C 2 T x MXene aqueous dispersion 10mL, ultrasonic dispersion uniform; nylon 66 thermoplastic elastomer beads placed in a critical CO 2 Carry out saturated absorption in an autoclave for 4 hours, the saturation temperature is 40°C, and the saturation pressure is 10MPa, and then the fully saturated thermoplastic elastomer beads are placed in a high-temperature oil bath for microcellular foaming, and the foaming temperature is 120°C. The foaming time was 15s to obtain nylon 66 microporous foam beads; the microporous foam beads were immersed in Ti 3 C 2 T x The aqueous MXene dispersion was taken out and placed in an oven at 40°C for drying to obtain Ti 3 C 2 T x MXene-wrapped nylon 66 thermoplastic elastomer composite microporous beads; the resulting Ti 3 C 2 T x MXene-wrapped thermoplastic elastomer composite microporous beads were placed in the mold, poured formic acid at a temperature of 40°C to dissolve the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com