Photocurable adhesive film for organic electronic device seal, organic electronic device, and method for sealing same

一种有机电子装置、粘合膜的技术,应用在薄膜/薄片状的粘合剂、没有载体的薄膜/薄片、粘合剂类型等方向,能够解决有机发光元件损害等问题,达到粘性时间缩短、机械强度简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

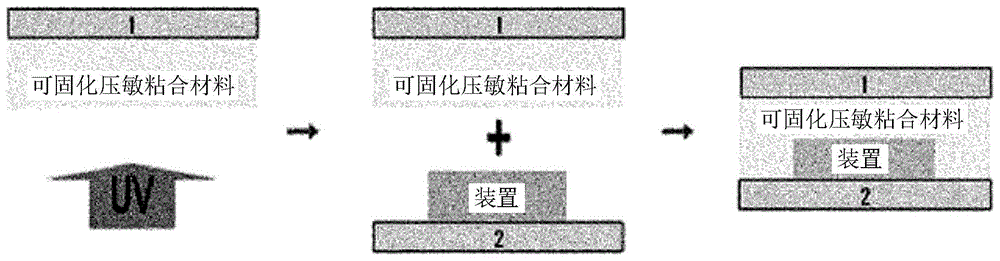

[0086] Example 1: Preparation of Curable Pressure Sensitive Adhesive Films and OEDs

[0087] By making a pressure sensitive adhesive containing 15 parts by weight of butyl acrylate, 40 parts by weight of methyl ethyl acrylate, 20 parts by weight of isobornyl acrylate, 15 parts by weight of methyl acrylate and 10 parts by weight of hydroxyethyl acrylate The mixture is polymerized to prepare an acrylic polymer with a glass transition temperature of about -20°C and a weight average molecular weight of 500,000.

[0088] With respect to 100 parts by weight of the above-mentioned acrylic polymer, 0.2 parts by weight of isocyanate crosslinking agent (xylyl diisocyanate, T-39M), 5 parts by weight of trimethylolpropane type epoxy resin (SR- TMP, SAKAMOTO) and 0.25 parts by weight of triaryl sulfonium salt type cationic photopolymerization initiator (CPI-110A, SAN-APRO Ltd.) add in this acrylic polymer, and add ethyl acetate as solvent, prepare solid content as 20% coating solution.

...

experiment example 1

[0099] Experimental Example 1: Measurement of Viscosity

[0100] The viscosities of the curable pressure-sensitive adhesive layers of the adhesive films according to Example 1 and Comparative Examples 1 to 4 before and after light irradiation were measured by ARES, and the results are listed in Table 1.

[0101] [Table 1]

[0102]

experiment example 2

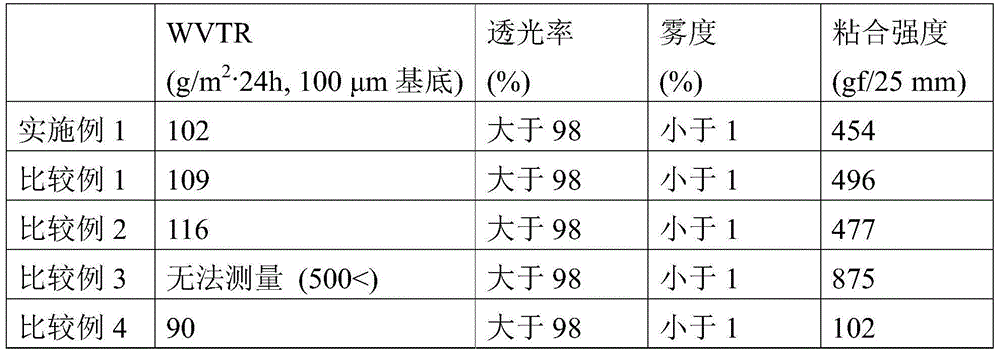

[0103] Experimental Example 2: Evaluation of WVTR

[0104] After thermally curing the curable pressure-sensitive adhesive films prepared in Example 1 and Comparative Examples 1 to 4, PERMATRAN-W Model3 / 61 manufactured by MOCON was used for 1cm 2 Area measurement WVTR. The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com