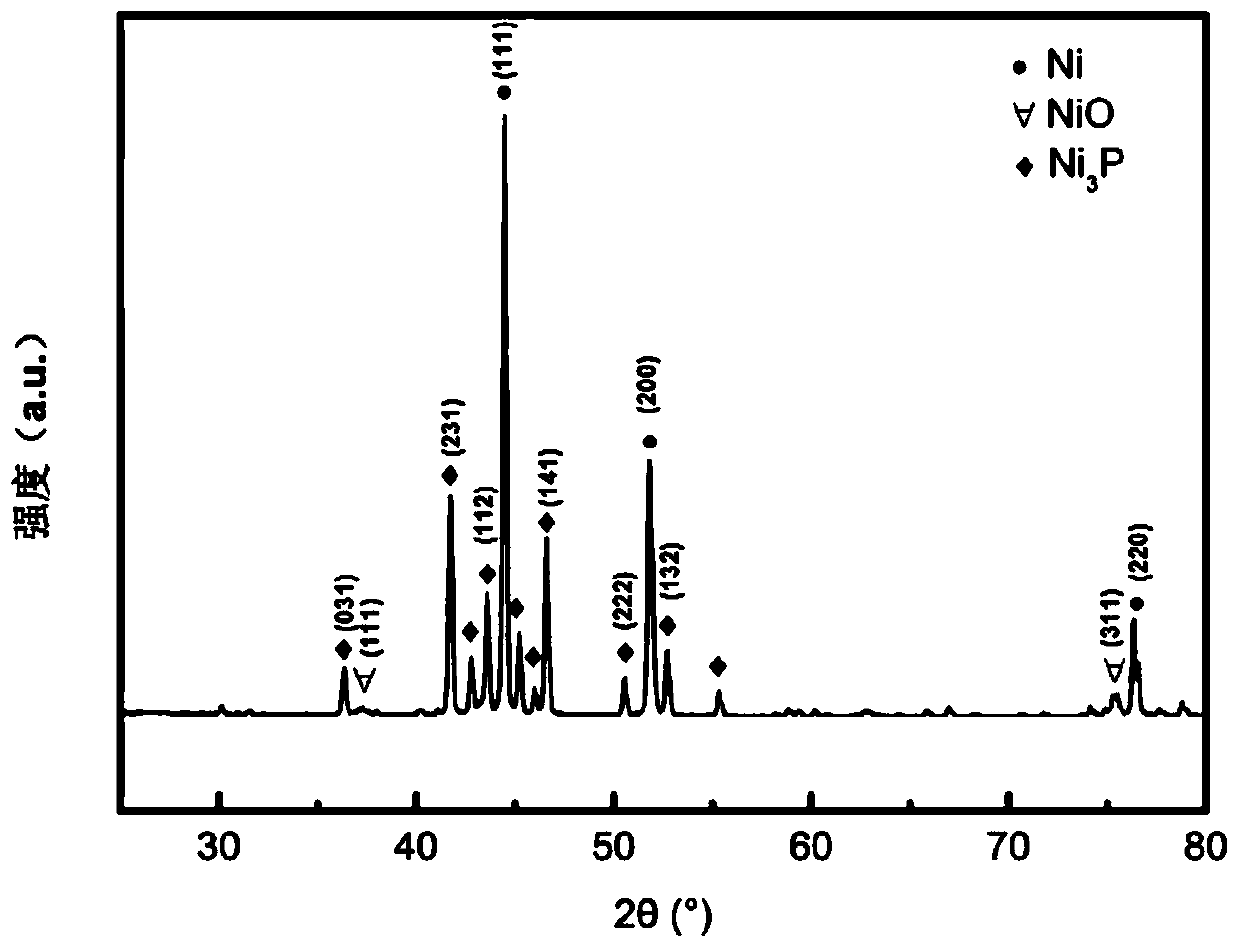

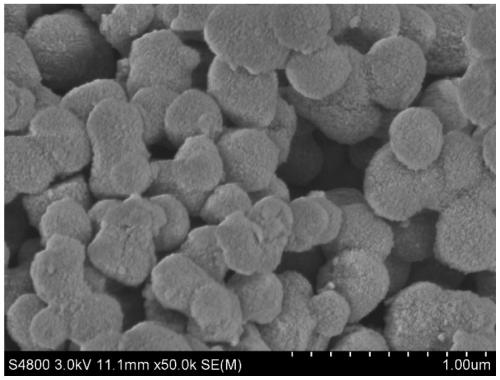

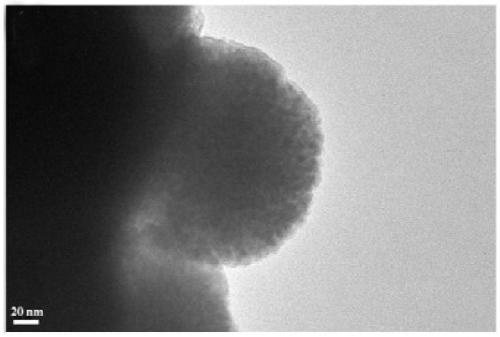

A nickel-phosphorus-oxygen micron-spherical lithium-ion battery negative electrode material and its preparation method and the prepared lithium-ion battery negative electrode

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low tap density and unfavorable performance of nanomaterials, and achieve the effects of low price, high yield and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of nickel phosphorus oxygen micron spherical lithium ion battery negative electrode material, comprising the following steps:

[0040] (1) Add 50g of choline chloride and 43.2g of urea into a 50ml three-necked flask, and stir at 80°C for 1 hour to obtain a deep eutectic solvent;

[0041] (2) Add 22g of dodecyltrimethylammonium bromide, ultrasonically dissolve, then add 0.47g of nickel chloride hexahydrate and 1.06g of sodium dihydrogen phosphate, and ultrasonically dissolve it for 1 hour to obtain a reaction precursor solution;

[0042] (3) Reflux the reaction precursor solution at 150°C for 3 hours. When the color changes from light green to black, stop the reflux, cool to room temperature, separate the precipitate by high-speed centrifugation, and wash it three times with deionized water and ethanol alternately, and finally , put the precipitate in a drying oven at 60° C., and dry it for 6 hours to obtain a black solid powder, which is the negativ...

Embodiment 2

[0051] A preparation method of nickel phosphorus oxygen micron spherical lithium ion battery negative electrode material, comprising the following steps:

[0052] (1) Add 50g of choline chloride and 43.2g of urea into a 50ml three-necked flask, and stir at 100°C for 1 hour to obtain a deep eutectic solvent;

[0053] (2) Add 22g of dodecyltrimethylammonium bromide, ultrasonically dissolve, then add 0.47g of nickel chloride hexahydrate and 0.53g of sodium dihydrogen phosphate, and ultrasonically dissolve it for 0.5 hours to obtain a reaction precursor solution;

[0054] (3) Reflux the reaction precursor solution at 120°C for 3 hours. When the color changes from light green to black, stop the reflux, cool to room temperature, separate the precipitate by high-speed centrifugation, and wash it three times with deionized water and ethanol alternately; finally , put the precipitate in a drying oven at 60°C, and dry it for 3 hours to obtain a black solid powder, which is the negative ...

Embodiment 3

[0063] A preparation method of nickel phosphorus oxygen micron spherical lithium ion battery negative electrode material, comprising the following steps:

[0064] (1) Add 50g of choline chloride and 21.6g of urea into a 50ml three-necked flask, and stir at 80°C for 1 hour to obtain a deep eutectic solvent;

[0065] (2) Add 11g of dodecyltrimethylammonium bromide, ultrasonically dissolve, then add 0.69g of nickel chloride hexahydrate and 1.06g of sodium dihydrogen phosphate, and ultrasonically dissolve it for 1 hour to obtain a reaction precursor solution;

[0066] (3) Reflux the reaction precursor solution at 100°C for 1.5 hours. When the color changes from light green to black, stop the reflux, cool to room temperature, separate the precipitate by high-speed centrifugation, and wash it three times with deionized water and ethanol alternately. Put the precipitate in a drying oven at 60°C and dry it for 6 hours to obtain a black solid powder, which is the negative electrode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com